Lakeshore Learning Materials 622 User Manual

Page 21

Lake Shore Model 620/622/623/647 Magnet Power Supply User’s Manual

Setup & Connections

2-5

2.5.6

MPS Analog Current And Voltage Monitoring Connections

The MPS provides amplified and buffered

current and voltage monitor output signals

at the terminal block on the back panel.

Connect these signals to external meters

to indicate output current and voltage.

Obtain the Current Monitor signal through

connections to terminals 9 (Im) and 11 (m)

with positive output currents producing a

positive monitor voltage of 10 mV/A from

Im to m.

Obtain the Voltage Monitor signal through

connections to terminals 10 (Vm) and

11 (m) with positive terminal voltages

producing a positive monitor voltage of

10 mV/V from Vm to m.

2.5.7

External Current Programming

Remotely program MPS output current by

an external voltage or potentiometer.

Enable external analog programming via

the rear panel I MODE switch. When the I

MODE switch is in the INT I position,

external current mode is disabled. When

the I MODE switch is in the EXT I position,

the external programming voltage is

summed with the internal programming

voltage. Set the internal programming to

zero for external programming only. Apply

an external voltage from lp to m of 0 to

1.25 volts or use a 10 K

Ω

potentiometer to

control the output current over the entire

range. Make connections to rear panel

detachable terminal block defined in

Tables 2-3 and 2-4 and Figures 2-1 and 2-

2. The MPS produces 100 A of output

current for 1 V at the current programming

input.

NOTE: MPS protection circuits reduce the

effect of open external programming leads.

An open external programming lead forces

external programming voltage to

approximately 0 volts.

2.5.8

Remote Sense Connections

The factory configures the MPS to sense, but not control remote voltage. Call Lake Shore to reconfigure the

MPS to control voltage at the load. When using remote sense, the MPS measures voltage at the magnet

instead of at the MPS output terminals allowing a more accurate reading of magnet voltage by eliminating

voltage drops in the leads connecting the MPS to the magnet. If using remote sense, the MPS bases the

voltage at the voltage monitor output on the remote sense voltage instead of the MPS terminal voltage.

Use AWG #24, shielded, twisted pair wiring for sense leads to minimize pickup of external noise. Any noise

on the sense leads may appear at the unit output. Ground sense shield to the MPS back panel.

Make Remote Sense Connections to the rear panel detachable terminal block defined in Table 2-3 and

Figure 2-2.

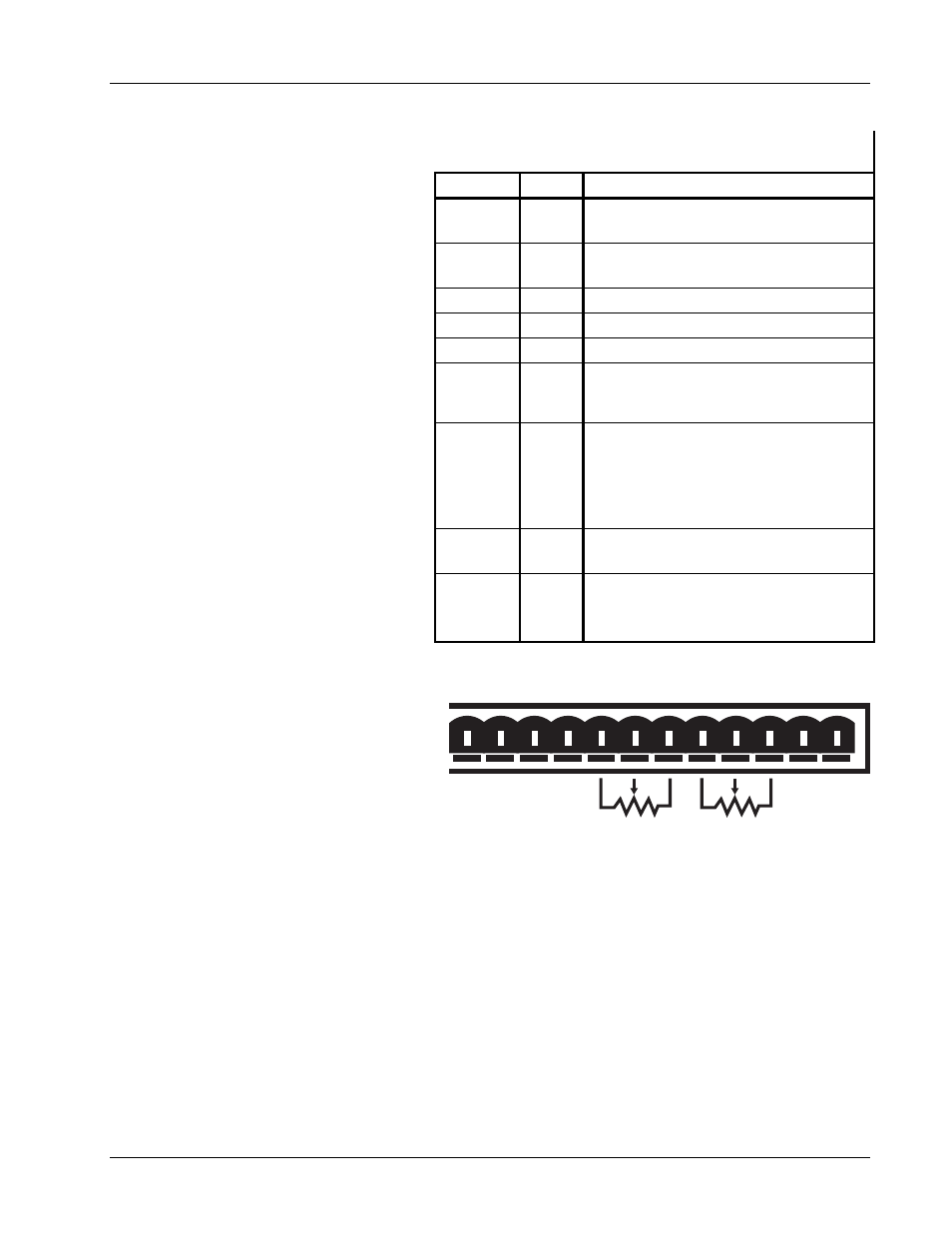

Table 2-2. Analog Monitoring, Programming,

and Remote Sense Connections

TERMINAL LABEL

DEFINITION

9

Im

Output Current Monitor – Voltage output

from Im to GND(M) is ±10 mV/A.

10

Vm

Output voltage monitor – Voltage output

from Vm to GND(M) is ±10 mV/V.

11

m

Monitor and program ground. GND(m).

12

Vp

Not Used.

13

+Vs

Not Used.

14

–Is

Negative voltage supply for

programming external current with a

potentiometer

15

Ip

Current programming input voltage.

Voltage input from Ip to GND(m)

produces ±100 A/V. Voltage may come

from a voltage source or from the center

tap of a potentiometer connected from -

Is to +Is.

16

+Is

Positive voltage supply for programming

external current with a potentiometer.

17

18

–S

+S

Remote voltage sense correction.

Correction for load lead drops of up to

0.5 V per lead.

10K

10K

7

8

9

10 11 12 13 14 15 16 17 18

OVP Im Vm m Vp +Vs -ls

lp +ls -S +S

Figure 2-2. Analog Monitoring , Programming,

and Remote Sense Connections