Kohler Aegis TP-2509 User Manual

Page 32

5.6

Section 5

Fuel System and Governor

Troubleshooting Checklist

When the engine starts hard, runs roughly or stalls at

low idle speed, check the following areas before

adjusting or disassembling the carburetor.

•

Make sure the fuel tank is filled with clean, fresh

gasoline.

•

Make sure the fuel tank cap vent is not blocked

and that it is operating properly.

•

Make sure fuel is reaching the carburetor. This

includes checking the fuel shut-off valve, fuel tank

filter screen, in-line fuel filter, fuel lines and fuel

pump for restrictions or faulty components as

necessary.

•

Make sure the air cleaner base and carburetor

are securely fastened to the engine using gaskets

in good condition.

•

Make sure the air cleaner element is clean and all

air cleaner components are fastened securely.

•

Make sure the ignition system, governor system,

exhaust system, and throttle and choke controls

are operating properly.

If the engine is hard-starting or runs roughly, or stalls at

low idle speed, it may be necessary to service the

carburetor.

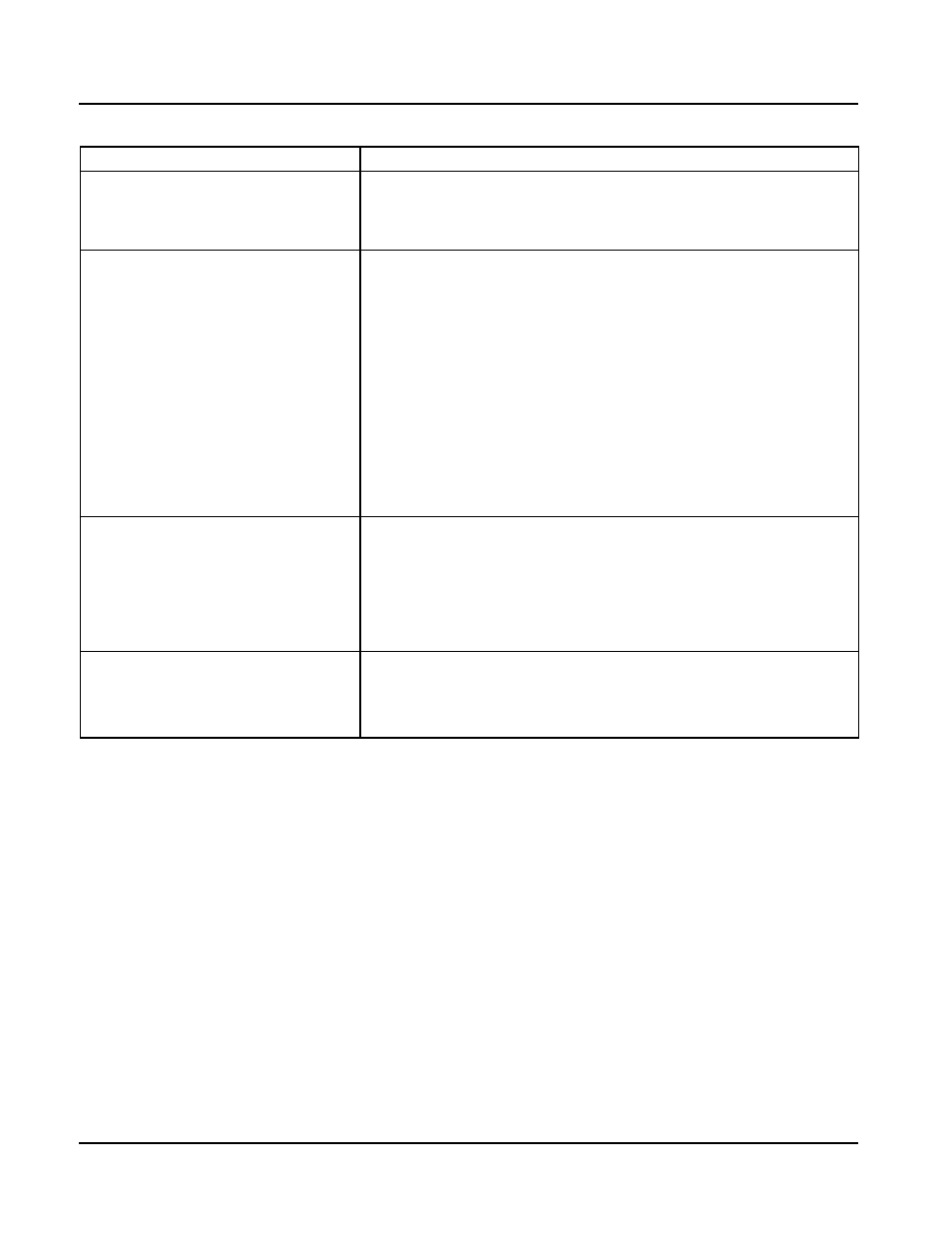

Troubleshooting – Carburetor Related Causes

Condition

Possible Cause/Probable Remedy

1a. Low idle speed improperly adjusted. Adjust the low idle speed

screw.

b. Low idle fuel mixture circuit blocked/restricted. Clean carburetor as

required.

1. Engine starts hard, runs roughly or

stalls at idle speed.

2. Engine runs rich (indicated by

black, sooty exhaust smoke,

misfiring, loss of speed and power,

governor hunting, or excessive

throttle opening).

2a. Clogged air cleaner. Clean or replace.

b. Choke partially closed during operation. Check the choke lever/

linkage to ensure choke is operating properly.

c. Float level too high. Separate fuel bowl from carburetor body. Free

(if stuck), or replace float.

d. Dirt under the fuel inlet needle. Remove needle; clean needle and

seat and blow with compressed air.

e. Bowl vent or air bleeds plugged. Clean vent, ports, and air bleeds.

Blow out all passages with compressed air.

f. Leaky, cracked, or damaged float. Submerge float to check for

leaks.

3. Engine runs lean (indicated by

misfiring, loss of speed and power,

governor hunting, or excessive

throttle opening).

3a. Float level too low. Separate fuel bowl from carburetor body. Free

(if stuck), or replace float.

b. Idle holes plugged; dirt in fuel delivery channels. Clean main fuel

jet and all passages; blow out with compressed air.

4. Fuel leaks from carburetor.

4a. Float stuck. See Remedy 2d.

b. Dirt under fuel inlet needle. See Remedy 2e.

c. Bowl vents plugged. Blow out with compressed air.

d. Carburetor bowl gasket leaks. Replace gasket.