Kohler Aegis TP-2509 User Manual

Page 107

11.3

Section 11

Reassembly

11

Figure 11-5. Proper Piston Connecting Rod

Orientation.

1. Stagger the piston rings in the grooves. The end

gaps of the top two rings should be 180° apart and

perpendicular to the rail end gaps, which should

also be 180° apart.

2. Lubricate cylinder bore, piston, and piston rings

with engine oil. Compress the rings using a piston

ring compressor.

3. Lubricate the crankshaft journals and connecting

rod bearing surfaces with engine oil.

4. Make sure ‘‘Fly’’ stamping on piston is facing

towards the flywheel side of the engine. Using the

grip end of a rubber grip hammer, bump the piston

down into the bore. Do not pound on piston.

5. Install the inner rod cap to the connecting rod

using the two 6 mm straight shank hex. flange

screws. Torque the screws in increments to

11.3 N·m (100 in. lb.). Illustrated instructions

are also provided in the service rod package.

NOTE: Make sure to align the chamfer of the

connecting rod with the chamfer of its

mating end cap. The chamfer should be

toward the outside.

6. Repeat the above procedure for the other

connecting rod and piston assembly.

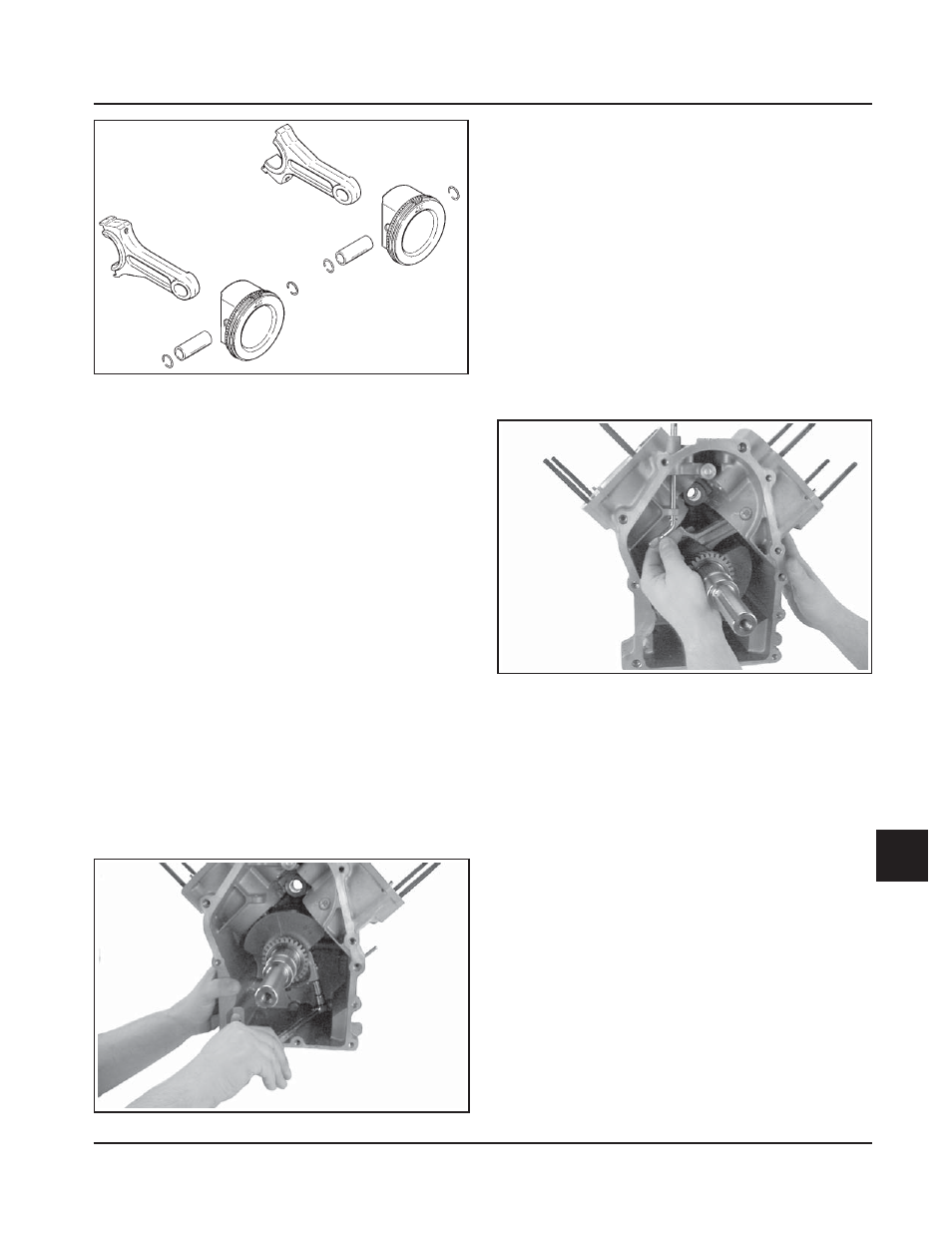

Install Governor Cross Shaft

1. Lubricate the governor cross shaft bearing

surfaces in the crankcase with engine oil.

2. Slide the small lower washer onto the governor

cross shaft and install the cross shaft from the

inside of the crankcase. See Figure 11-7.

Cylinder #1

Cylinder #2

Figure 11-6. Torquing Rod Cap Bolts.

Figure 11-7. Installing Governor Cross Shaft from

the Inside.

3. Install the nylon washer onto the governor cross

shaft, then start the push-on retaining ring. Hold

the governor shaft up in position, place a 0.25

mm (0.010 in.) feeler gauge on top of the nylon

washer, and push the retaining ring down the

shaft to secure. Remove the feeler gauge, which

will have established the proper end play. See

Figure 11-8.