Troubleshooting, Se rv ic e – Woodstock M1013 User Manual

Page 34

-32-

M1013 Owner's Manual (Mfg. Since 6/09)

SE

RV

IC

E

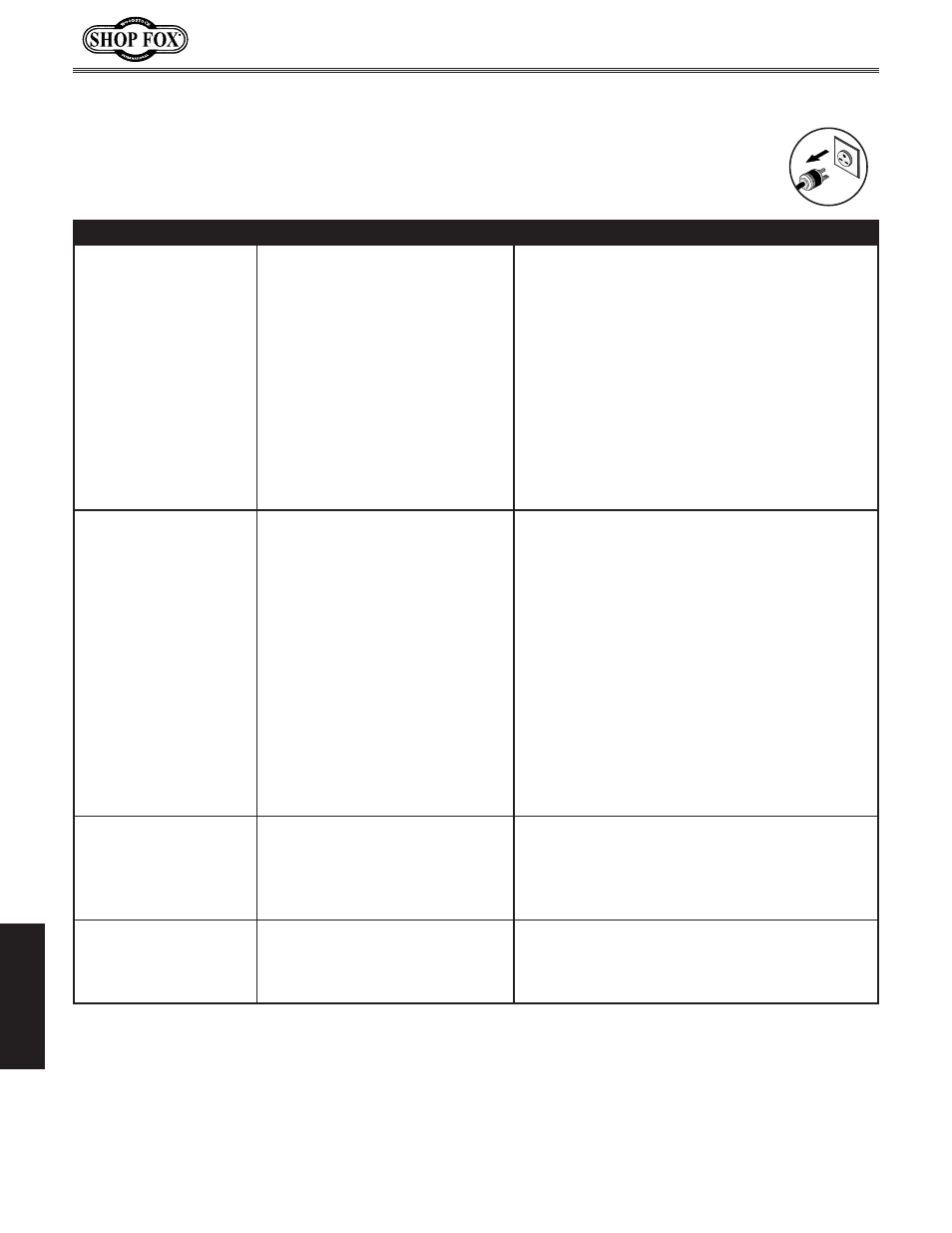

Troubleshooting

This section covers the most common problems and corrections with this type of

machine.

WARNING! DO NOT make any adjustments until power is disconnected and

moving parts have come to a complete stop!

PROBLEM

POSSIBLE CAUSE

CORRECTIVE ACTION

Machine does not start or a

breaker trips.

1. Plug/receptacle is at fault or wired

incorrectly.

2. Start capacitor is at fault.

3. Wall fuse/circuit breaker is blown/

tripped.

4. Motor connection wired incorrect-

ly.

5. Power supply is at fault/switched

OFF.

6. Motor ON/OFF switch is at fault.

7. Wiring is open/has high resistance.

8. Motor is at fault.

1. Test for good contacts; correct the wiring.

2. Test/replace if faulty.

3. Ensure correct size for machine load; replace weak

breaker.

4. Correct motor wiring connections.

5. Ensure hot lines have correct voltage on all legs and

main power supply is switched ON.

6. Replace faulty ON/OFF switch.

7. Check for broken wires or disconnected/corroded

connections, and repair/replace as necessary.

8. Test/repair/replace.

Machine stalls or is under-

powered.

1. Wrong blade for the workpiece

material.

2. Wrong workpiece material.

3. Feed rate/cutting speed too fast

for task.

4. Blade is slipping on wheels.

5. Low power supply voltage.

6. Motor bearings are at fault.

7. Plug/receptacle is at fault.

8. Motor connection is wired incor-

rectly.

9. Motor has overheated.

10. Motor is at fault.

1. Use blade with correct properties for your type of

cutting.

2. Use metal with correct properties for your type of

cutting.

3. Decrease feed rate/cutting speed.

4. Adjust blade tracking and tension.

5. Ensure hot lines have correct voltage on all legs.

6. Test by rotating shaft; rotational grinding/loose

shaft requires bearing replacement.

7. Test for good contacts; correct the wiring.

8. Correct motor wiring connections.

9. Clean off motor, let cool, and reduce workload.

10. Test/repair/replace.

Machine has vibration or

noisy operation.

1. Motor fan is rubbing on fan cover.

2. Blade is at fault.

3. Gearbox is at fault.

4. Wrong blade & too slow of speed.

1. Replace dented fan cover; replace loose/damaged

fan.

2. Replace/resharpen blade.

3. Rebuild gearbox for bad gear(s)/bearing(s).

4. Change blade and or speed.

Machine is loud when cut-

ting or bogs down in the

cut.

1. Excessive feed rate.

2. The blade TPI is too great, or the

material is too coarse.

1. Refer to

Feed Rate on Page 25, or Blade Speed on

Page 23, and adjust as required.

2. Refer to

Blade Selection on Page 24 and adjust as

required.