Maintenance, Cleaning, General – Woodstock M1013 User Manual

Page 28: Lubrication

-26-

M1013 Owner's Manual (Mfg. Since 6/09)

M

A

INTE

N

A

N

CE

MAINTENANCE

Keeping metal chips away from bandsaw mechanisms is

important to ensure that your bandsaw lasts a long time.

Use a shop vacuum or brush-off metal chips frequently.

Cleaning

Regular periodic maintenance on your machine will

ensure its optimum performance. Make a habit of

inspecting your machine each time you use it.

Check for the following conditions and repair or

replace when necessary:

• Loose mounting bolts.

• Missing or leaking rubber toggle switch boots.

• Worn or damaged cords, switches, or plugs.

• Damaged V-belt.

• Any other condition that could hamper the safe

operation of this machine.

General

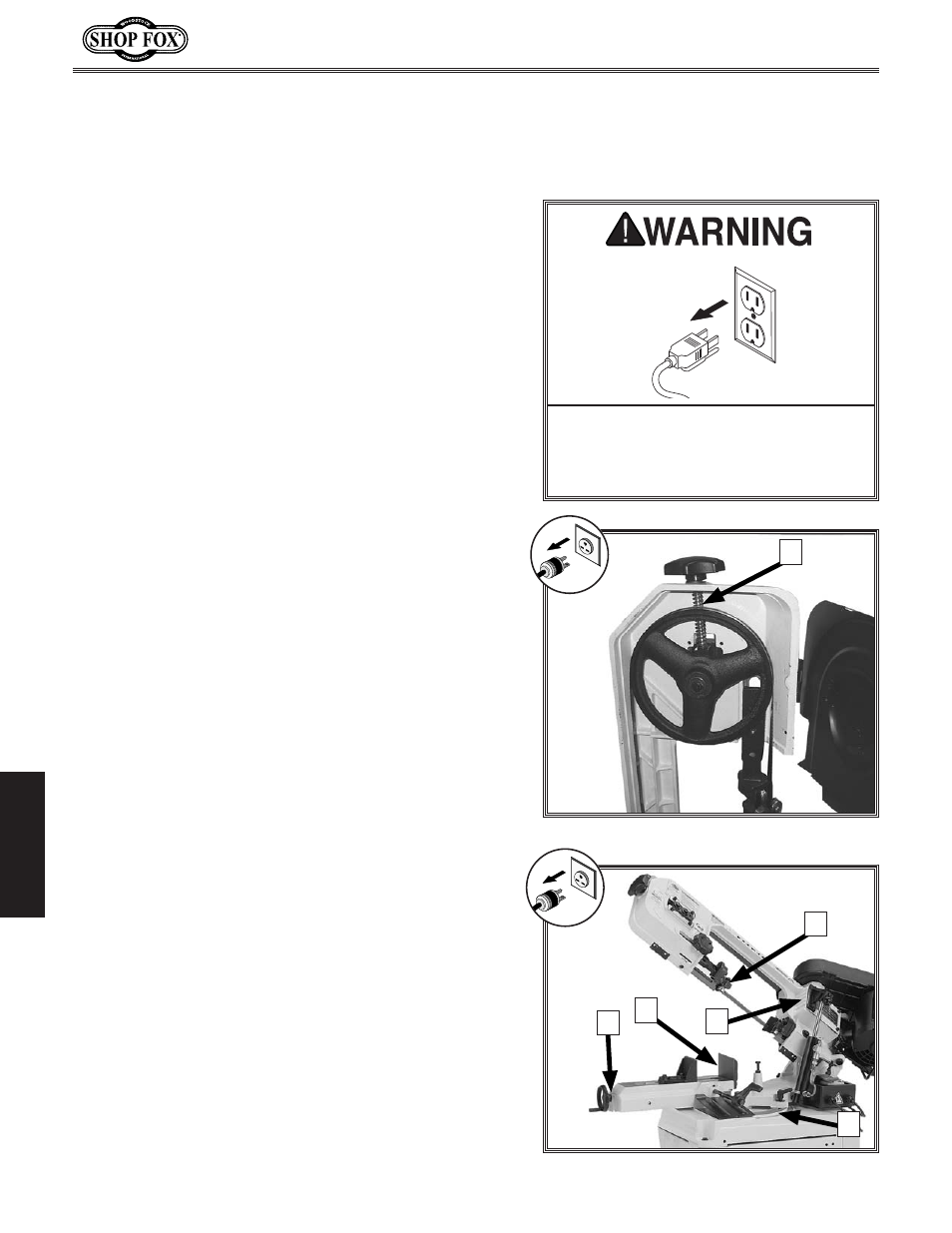

MAKE SURE that your machine is

unplugged during all maintenance pro-

cedures! If this warning is ignored, seri-

ous personal injury may occur.

The gearbox and all bearings are sealed and permanently

lubricated and no scheduled lubrication is needed.

However, you must periodically lubricate adjustment

locations and bare metal surfaces. Refer to

Figures

29—30 for lubrication points.

Lubricate the following areas listed below:

A. Blade Tension Mechanism: Open the main blade

guard, and drop a few drops of oil on the tension

knob lead screw.

B. Blade and Guides: Drop a few drops of light machine

oil on the blade and the blade guides daily.

C. Gear Box: Is packed with grease and should only be

changed if you suspect contamination.

D. Table and Machined Surfaces: Keep bare metal

surfaces rust-free with regular applications of

products like SLIPIT

®

. For long term storage you may

want to consider products like Boeshield T-9™.

E. Vise Lead Screw: Drop a few drops of light machine

oil on the vise lead screw weekly.

Lubrication

Figure 29. Lubrication points.

A

Figure 30. Lubrication points.

B

D

C

D

E