Blade tension – Woodstock M1013 User Manual

Page 20

-18-

M1013 Owner's Manual (Mfg. Since 6/09)

SE

TU

P

Blade Tension

Proper blade tension is essential to long blade life,

straight cuts, and efficient cutting.

Two major signs that you do not have proper blade

tension are: 1) the blade stalls in the cut and slips on the

wheels, and 2) the blade frequently breaks from being too

tight.

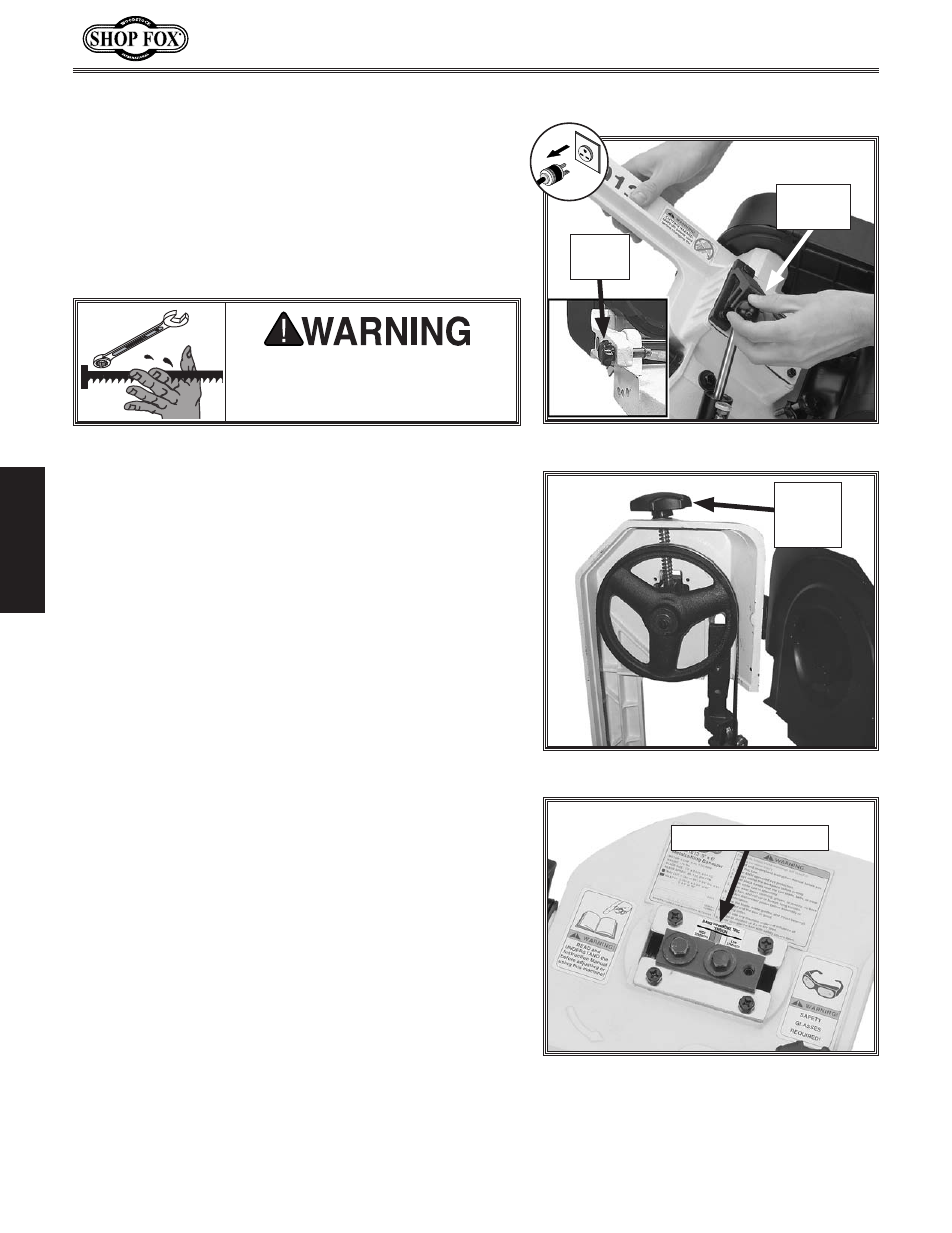

Figure 20. Typical blade tension scale.

Blade Tension Scale

Disconnect bandsaw from power

BEFORE making and adjustments

to the machine!

Figure 18. Raising and locking headstock.

Safety

Stop

Cylinder

Lock Pin

Figure 19. Blade tension adjustment knob.

Blade

Tension

Knob

To set the blade tension, do these steps:

1. Make sure the blade is tracking properly (refer

to

Blade Tracking on Page 29 for detailed

instructions).

2. Remove the cylinder lock pin, raise the headstock to

the full vertical position, and push the safety stop

inward to lock the headstock in the vertical position

(see

Figure 18).

3. Open the blade cover, as shown in Figure 19, slide

the blade guides as far apart as possible, then

secure them in place

4. Turn the blade tension knob until the blade is snug,

and the blade tension scale indicates "medium" (see

Figure 20).

5. Adjust the blade guides as instructed in the next

subsection

6. Close and secure the blade guard.