Spring tension, Chip deflector positioning – Grizzly G1033X User Manual

Page 39

Model g1033X (Mfg. since 4/12)

-37-

Spring Tension

Tools Needed:

Qty

hex Wrench 6mm .............................................. 1

roller spring tension must be adjusted so that

feed roller pressure is uniform. roller spring ten-

sion will vary, depending on the type of wood you

plane. this is usually determined from trial-and-

error.

generally speaking, less spring tension is more

forgiving on workpieces. therefore, if you primar-

ily plane milled lumber with relatively consistent

surfaces, you can get away with having less

spring tension. likewise, if you primarily plane

rough lumber with inconsistent surface heights,

more spring tension is a must to keep the

workpiece feeding through the planer without

stopping.

if workpieces regularly stop feeding during opera-

tion, it may be a sign of weak spring tension.

To adjust feed roller spring tension:

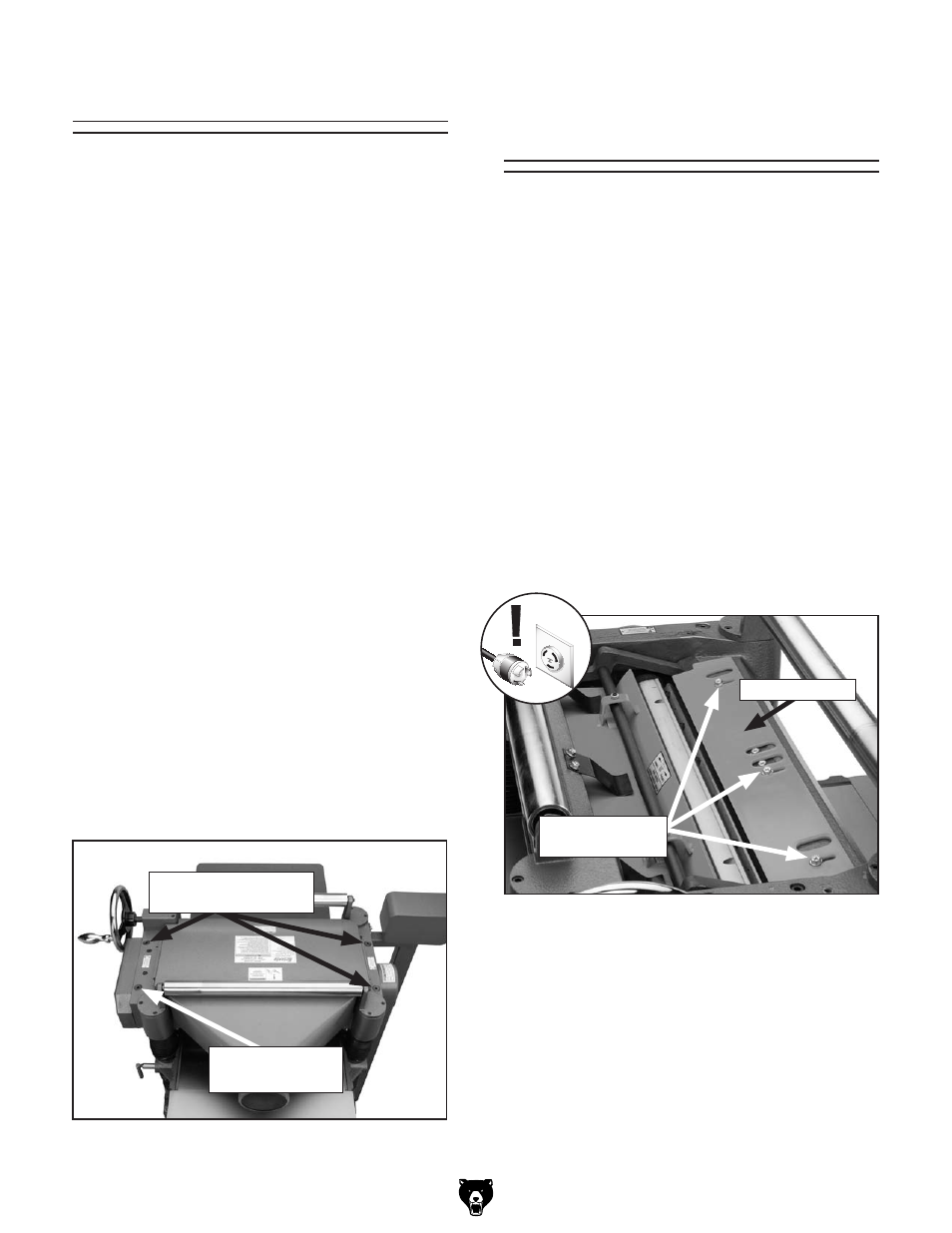

1. locate the four adjustment screws located

on the top of the planer, as shown in

figure

36.

2. Adjust tension screws #1–#3 so that they

protrude

1

⁄

8

" above the head casting.

3. Adjust tension screw #4 so that it protrudes

5

⁄

16

" above the head casting.

figure 36. tension screw locations and

adjustments.

tension screws

#1 - #3 Adjust to

1

⁄

8

"

tension screw

#4 Adjust to

5

⁄

16

"

Chip Deflector

Positioning

Chip Deflector Gap Setting

if planer Used w/dust Collector ......................

1

⁄

4

''

if planer Used w/o dust Collector .................

1

⁄

16

''

Tools Needed:

Qty

Wrench or socket 10mm ................................... 1

hex Wrench 5mm .............................................. 1

the chip deflector keeps chips from falling onto

the outfeed roller.

To adjust the deflector position:

1. disConnECt thE plAnEr FroM thE

poWEr soUrCE!

2. remove the dust port and top cover.

3. loosen the chip deflector mounting bolts

(see

figure 37).

Chip deflector

figure 37. Chip deflector and mounting bolts.

4. Make sure the deflector is beveled toward the

cutterhead. Move the deflector until the edge

is the correct distance (given above) from the

closest carbide insert. Use the cutterhead

pulley to rotate the cutterhead to ensure

clearance.

5. re-tighten the mounting bolts and return the

top cover to the planer.

Chip deflector

Mounting Bolts