Bed rollers – Grizzly G1033X User Manual

Page 27

Model g1033X (Mfg. since 4/12)

-25-

To adjust the bed rollers:

1. disConnECt plAnEr FroM poWEr!

2. lower the table to give yourself at least 4" of

working room below the cutterhead.

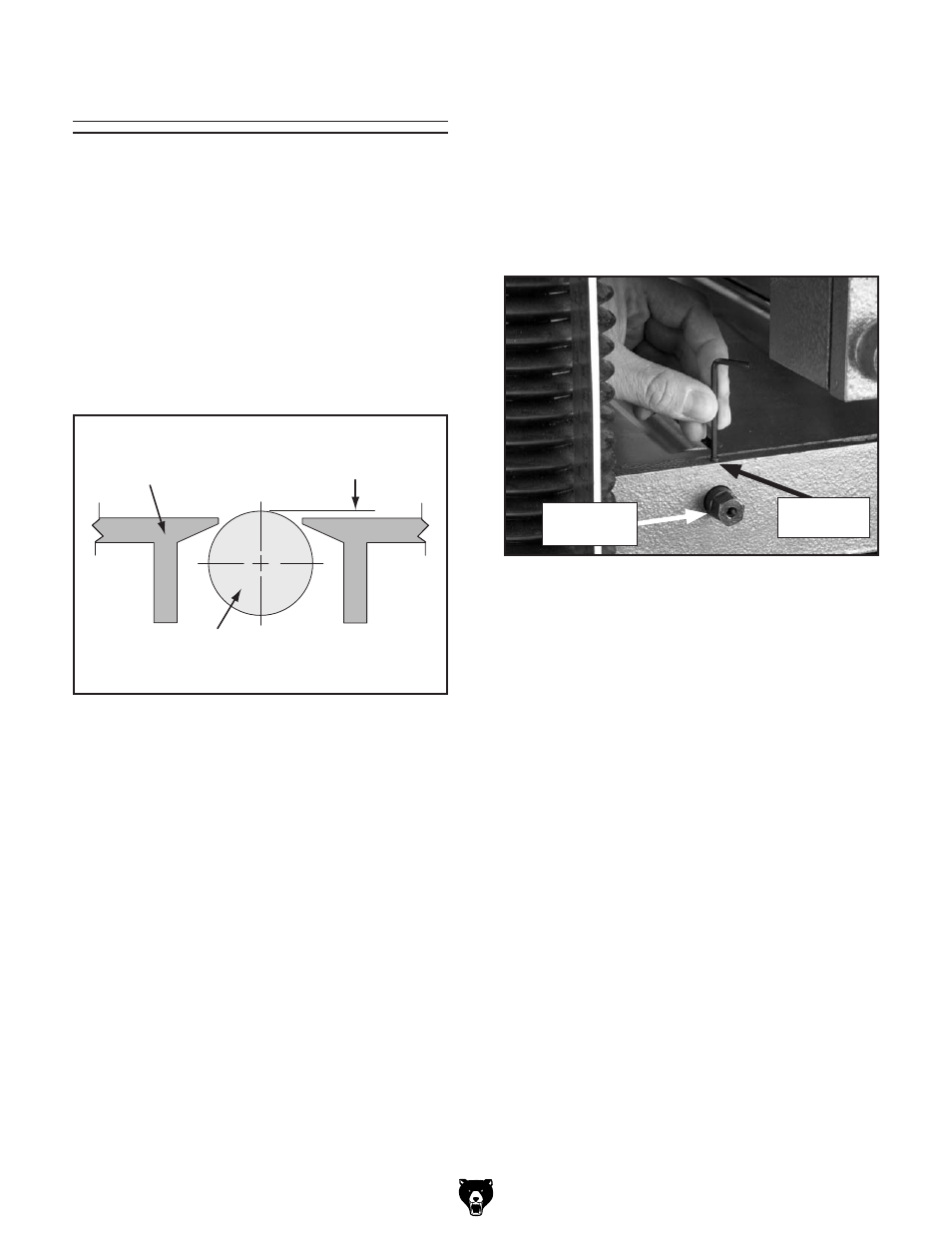

3. loosen the locking set screws (figure 18)

above the roller adjusters (4 total).

4. raise or lower the rollers by rotating the

adjusters to reach your desired height.

5. verify both sides of the bed roller are at the

same height and lock them in position with

the locking set screws.

6. double check the roller heights to make sure

they did not move when you locked them (if

they did, repeat the procedure).

figure 18. Bed roller controls (only one side

shown).

locking

set screw

roller

Adjuster

bed Rollers

Bed roller height range ..............0.002"–0.020"

Tools Needed:

Qty

hex Wrench 3mm .............................................. 1

open End Wrench 14mm .................................. 1

rotacator (optional,

Page 26) ........................... 1

the height of the bed rollers will vary, depend-

ing on the type of material you intend to plane,

however, as a general rule, keep the roller height

within 0.002"–0.020" above the table surface, as

illustrated in

figure 17.

figure 17. Bed roller height range.

GdaaZg

IVWaZ

%#%%'¶%#%'%

to ensure accurate results and make the adjust-

ment process quicker and easier, we recommend

using a rotacator (see

Page 26) to gauge the bed

roller height from the table. if a rotacator is not

available, a straightedge and feeler gauges can

be used, but extra care must be taken to achieve

satisfactory results.

Note: Misaligned bed rollers can cause workpiece

chatter, a washboard surface, uneven workpiece

feeding, or binding.

When planing rough stock, set the rollers high

to keep the lumber from dragging along the bed.

When planing milled lumber, set the rollers low to

help minimize snipe.