Workpiece inspection, Wood hardness – Grizzly G1033X User Manual

Page 25

Model g1033X (Mfg. since 4/12)

-23-

Workpiece

Inspection

some workpieces are not safe to plane or may

require modification before they are safe to pass

through the planer.

before cutting, inspect all

workpieces for the following:

•

Material Type: this machine is only intend-

ed for planing workpieces of natural wood.

Attempting to plane workpieces of any other

material, including wood composites, could

lead to serious personal injury and property

damage.

•

foreign Objects: inspect lumber for defects

and foreign objects (nails, staples, imbedded

gravel, etc,). if you have any question about

the quality of your lumber, do not use it.

remember, wood stacked on a concrete floor

can have small pieces of stone or concrete

pressed into the surface.

•

Large/Loose Knots: loose knots can

become dislodged during the planing opera-

tion. large knots can cause kickback and

machine damage. Choose workpieces that

do not have large/loose knots when planing.

•

Wet or "Green" Stock: Avoid planing wood

with a high water content. Wood with more

than 20% moisture content or wood exposed

to excessive moisture (such as rain or snow),

will plane poorly and cause excessive wear

to the cutterhead and motor. Excess mois-

ture can also hasten rust and corrosion of the

planer and/or individual components.

•

Excessive Warping: Workpieces with exces-

sive cupping, bowing, or twisting are danger-

ous to cut because they are unstable and

often unpredictable when being planed. do

not use workpieces with these characteris-

tics!

•

Minor Cupping: Workpieces with slight cup-

ping can be safely supported if the cupped

side is facing the planer table. on the con-

trary, a workpiece supported on the bowed

side will rock during planing and could cause

severe injury from kickback.

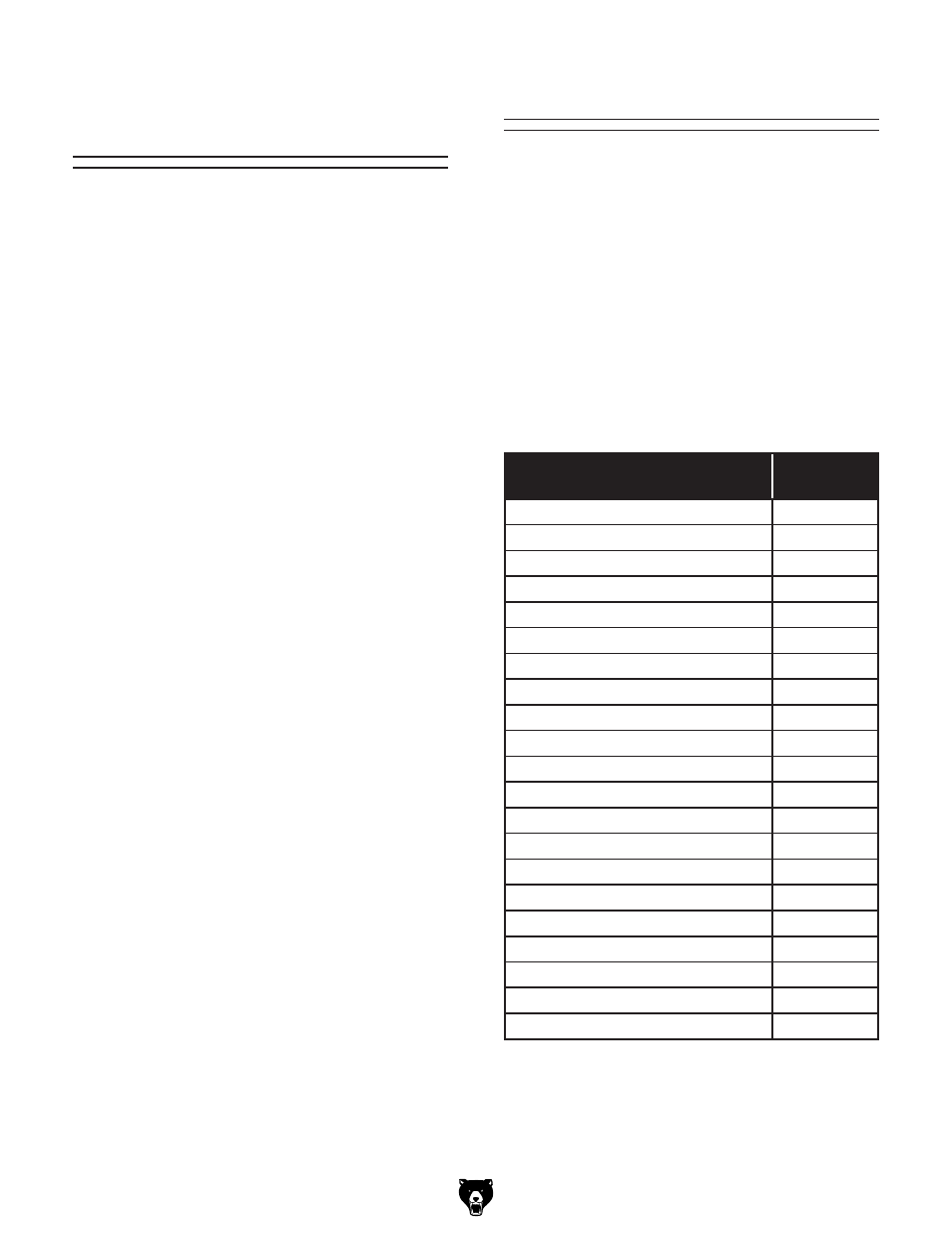

Wood Hardness

the species of wood, as well as its condition,

greatly affects the depth of cut the planer can

effectively take with each pass.

the chart in

figure 14 shows the Janka hardness

rating for a number of commonly used species.

the larger the number, the harder the workpiece,

and the less material to be removed in any one

pass for good results.

Note: The Janka Hardness Rating is expressed in

pounds of force required to embed a 0.444" steel

ball into the surface of the wood to a depth equal

to half the ball's diameter.

Species

Janka

Hardness

Ebony

3220

red Mahogany

2697

rosewood

1780

red pine

1630

sugar Maple

1450

White oak

1360

White Ash

1320

American Beech

1300

red oak

1290

Black Walnut

1010

teak

1000

Black Cherry

950

Cedar

900

sycamore

770

douglas Fir

660

Chestnut

540

hemlock

500

White pin

420

Basswood

410

Eastern White pine

380

Balsa

100

figure 14. Janka hardness rating for some

common wood species.