Chain tension notice, Table parallelism – Grizzly G1033X User Manual

Page 34

-32-

Model g1033X (Mfg. since 4/12)

Tools Needed:

Qty

phillips screwdriver #2 ...................................... 1

Wrench or socket 14mm ................................... 1

the chain drive transfers movement from the

handwheel to elevate the table. the chain drive

can be adjusted to remove slack if the chain

stretches over time or is loosened during table

leveling procedures.

To adjust the chain tension:

1. disConnECt thE plAnEr FroM thE

poWEr soUrCE!

2. remove the motor access panel.

Chain Tension

NOTICE

During the next step, DO NOT let the chain

fall off the sprockets—returning it to its

proper location without changing the table

adjustments can be very difficult.

4. re-tighten the two locking bolts.

5. Check chain lubrication. refer to SECTION

6: MAINTENANCE on Page 27 for further

details.

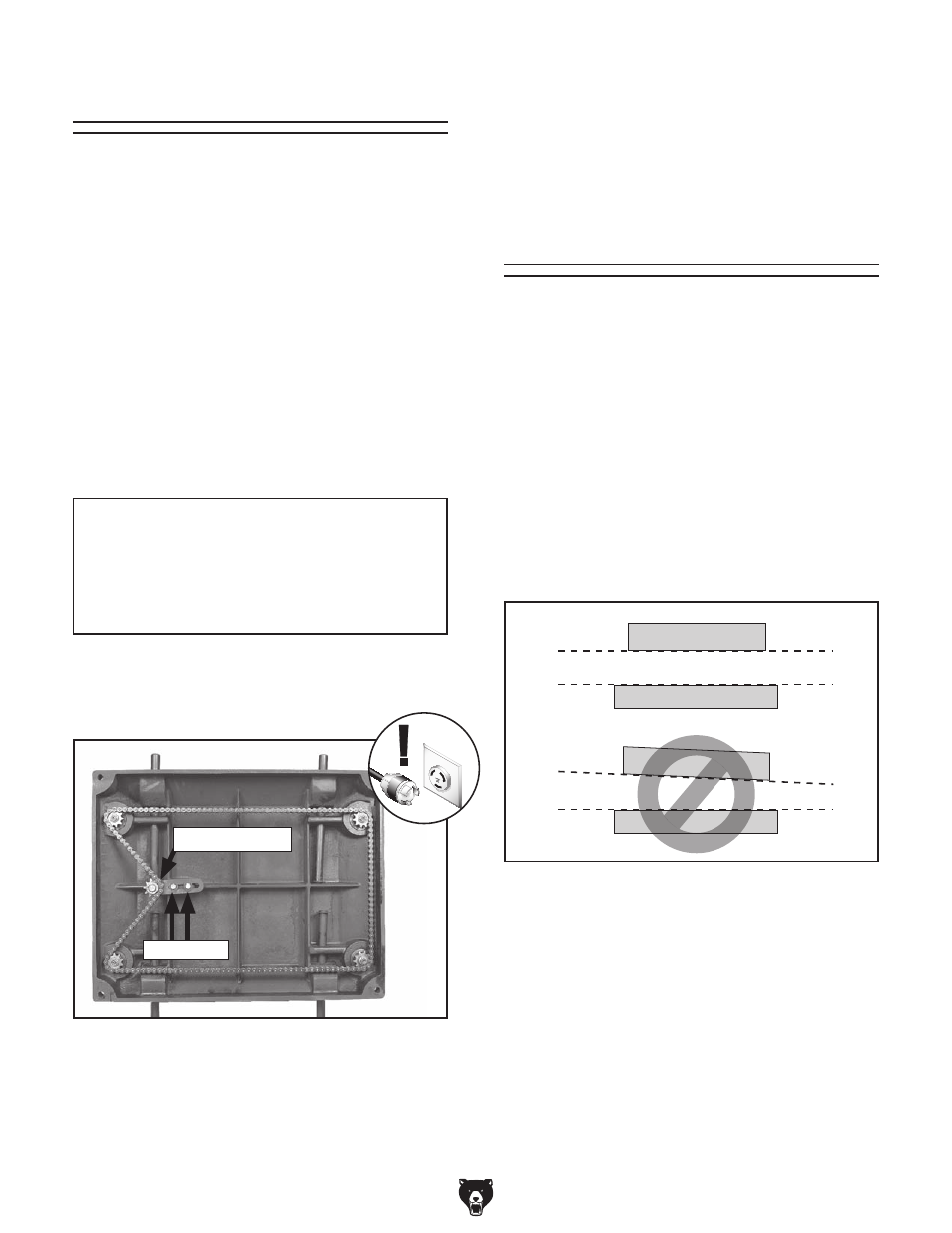

figure 26. Underside of table.

lock Bolts

idler sprocket

3. loosen the two lock bolts and move the

idler sprocket against the chain to tighten it

(

figure 26).

Table Parallelism

Maximum Allowable Tolerances:

Cutterhead/table side-to-side ..................0.002"

head Casting/table Front/Back ................ 0.020"

Tools Needed:

Qty

rotacator ........................................................... 1

phillips screwdriver #2 ...................................... 1

Wrench or socket 14mm ................................... 1

hex Wrench 6mm .............................................. 1

table parallelism is critical to the operation of the

machine. As such, it is essential that the table is

parallel with the cutterhead (within 0.002") from

side-to-side, as illustrated in

figure 27.

figure 27. side-to-side parallelism of table and

cutterhead.

8jiiZg]ZVY

8jiiZg]ZVY

IVWaZ

IVWaZ

EVgVaaZa

EVgVaaZa

Cdi"EVgVaaZa

Cdi"EVgVaaZa

&2/.4

6)%7

3)$% 4/ 3)$%