Internal component heights – Grizzly G1033X User Manual

Page 36

-34-

Model g1033X (Mfg. since 4/12)

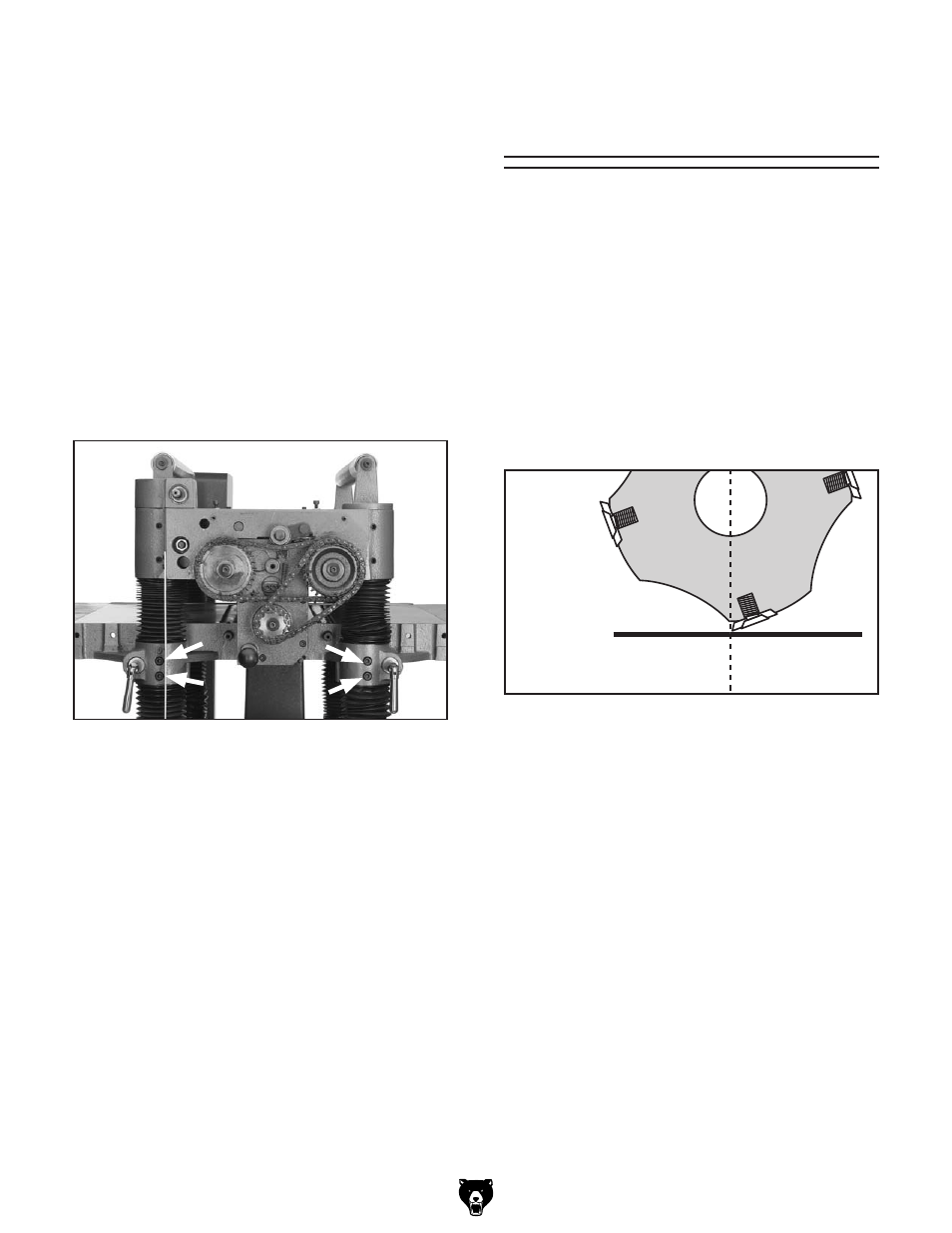

figure 29. table micro-adjustment screws.

7. repeat Steps 4–6 with each sprocket that

needs to be adjusted until the table-to-

cutterhead clearance is within 0.016" from

one side to the other.

8. Make sure the chain is properly fitted on the

sprockets, and tighten the idler sprocket and

lock bolts.

9. Micro-adjust the table position by loosening

the cap screws shown in

figure 29 and lifting

the table upward or downward until the table

and cutterhead are in alignment.

Note: This process may require adjusting the

columns on both the left and right hand sides

until you find the correct combination.

Internal Component

Heights

Distance below Cutter Edge at *bDC

infeed roller .............................................. 0.040"

Chip Breaker .............................................. 0.040"

pressure Bar .............................................. 0.040"

outfeed roller ........................................... 0.040"

Tools Needed:

Qty

hex Wrench 3mm .............................................. 1

hex Wrench 5mm .............................................. 1

Wrench or socket 10mm ................................... 1

rotacator (optional,

Page 26) ........................... 1

*BdC = Bottom dead Center (see

figure 30).

to ensure accurate results and make the adjust-

ment process quicker and easier, we recommend

using a rotacator (see

Page 26) for these adjust-

ments.

if a rotacator is not available, a 6' 2x4 cut into two

even sized pieces and a 0.40" feeler gauge can

be used, but care must be taken when jointing the

blocks to achieve accurate results.

To set the height of the infeed and outfeed

rollers, chip breaker, and pressure bar using

a Rotacator:

1. disConnECt thE plAnEr FroM thE

poWEr soUrCE!

figure 30. Carbide insert at bottom dead center

Ide9ZVY

8ZciZg

7diidb9ZVY

8ZciZg