Notice – Grizzly G1033X User Manual

Page 35

Model g1033X (Mfg. since 4/12)

-33-

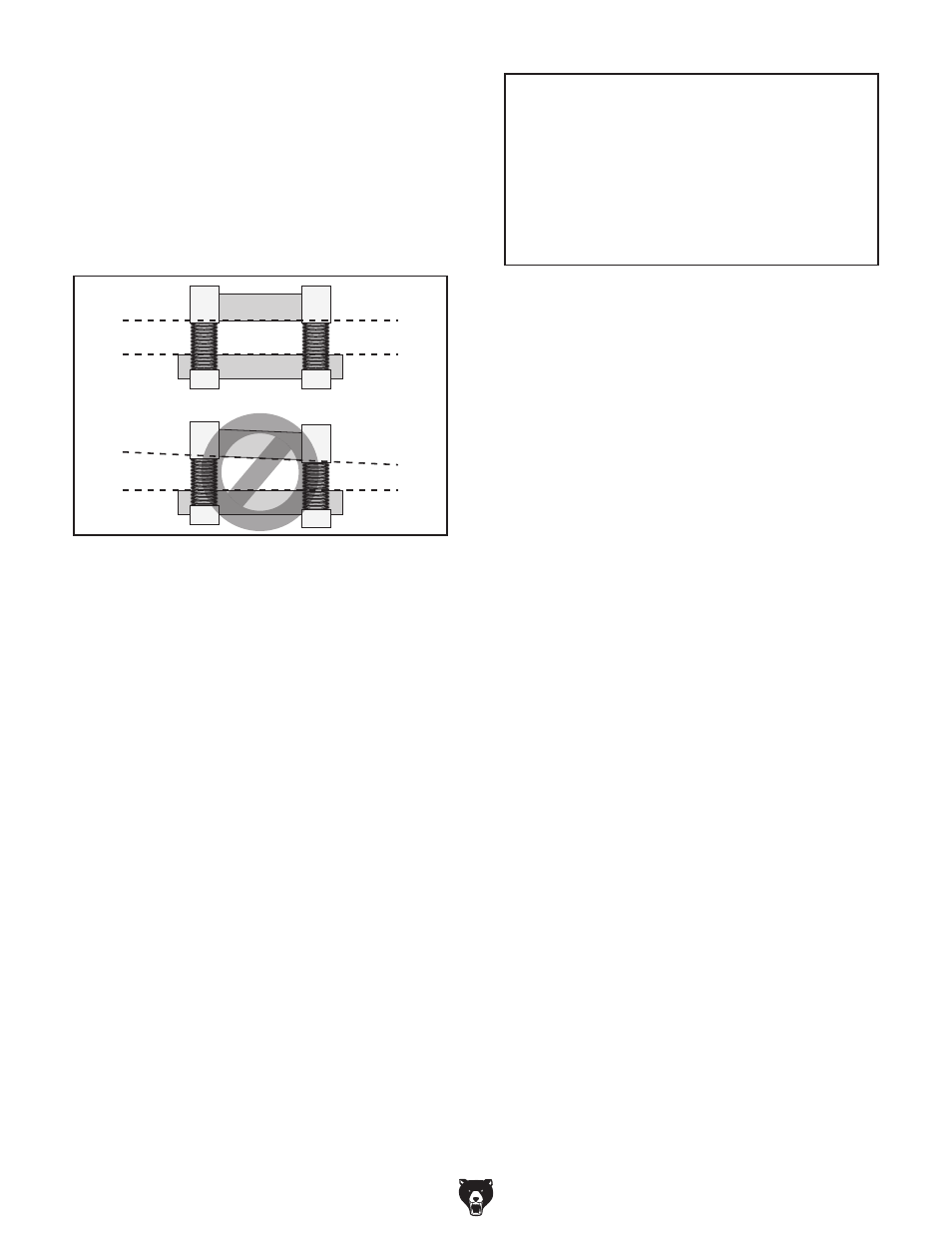

figure 28. Front-to-back parallelism.

IVWaZ

IVWaZ

=ZVY

=ZVY

EVgVaaZa

EVgVaaZa

Cdi"EVgVaaZa

Cdi"EVgVaaZa

&2/.4

"!#+

how the table sits in relation to the head casting

from front-to-back is also important (see

figure

28). Because the feed rollers, pressure bar, and

chip breaker will be adjusted off the table position,

the tolerances on the front-to-back positioning are

not as critical as the cutterhead/table side-to-side

positioning. therefore, the maximum allowable

tolerance for the front-to-back parallelism is not

more than 0.020".

Table Parallelism Inspection

the easiest way to determine if your head casting

has a parallelism problem is to plane a workpiece

and measure the thickness in multiple locations. if

the workpiece is tapered from left-to-right or from

front-to-back, then parallelism may be a problem.

Use your rotacator to further inspect the table

parallelism. if you do not have a rotacator, a

wood block and feeler gauges may be used, but

extra care must be taken to ensure accuracy. if

the table is not within the maximum allowable

tolerances, it must be adjusted.

Table Parallelism Adjustments

the table is adjusted by turning the chain sprock-

ets underneath the table for movements over

0.016" or by adjusting how the table is mounted

on the columns for movements under 0.016".

To adjust the table parallelism:

1. disConnECt thE plAnEr FroM thE

poWEr soUrCE!

2. remove the motor access panel and locate

the chain on the underside of the table.

3. loosen the lock bolts and idler sprocket (see

Chain Tension instructions on Page 32).

4. Mark the location of one tooth in the sprocket

that you are adjusting.

5. Move the chain away from only the sprocket

you want to adjust so only that sprocket can

be turned independent of the chain.

Note: If the left side of the table is too high,

the left two sprockets will need to be adjusted.

Each tooth on the sprocket represents 0.016"

of vertical movement as the cogs are turned.

Make sure, as you turn the sprockets, to keep

an accurate tooth count to ensure that the

table is adjusted equally.

6. Carefully turn the sprocket (clockwise to

raise the table; counterclockwise to lower the

table) just enough to position the next tooth at

the marked location, then fit the chain around

sprocket again.

NOTICE

When making adjustments, tighten fasten-

ers after each step to ensure the accuracy

of your tests. When adjusting the chain

sprockets, keep in mind that if the chain

becomes too loose, it will fall off of all the

sprockets. Returning it to its proper loca-

tion can be frustrating.