Roubleshooting, Hart – Goodman Mfg MVC95 User Manual

Page 55

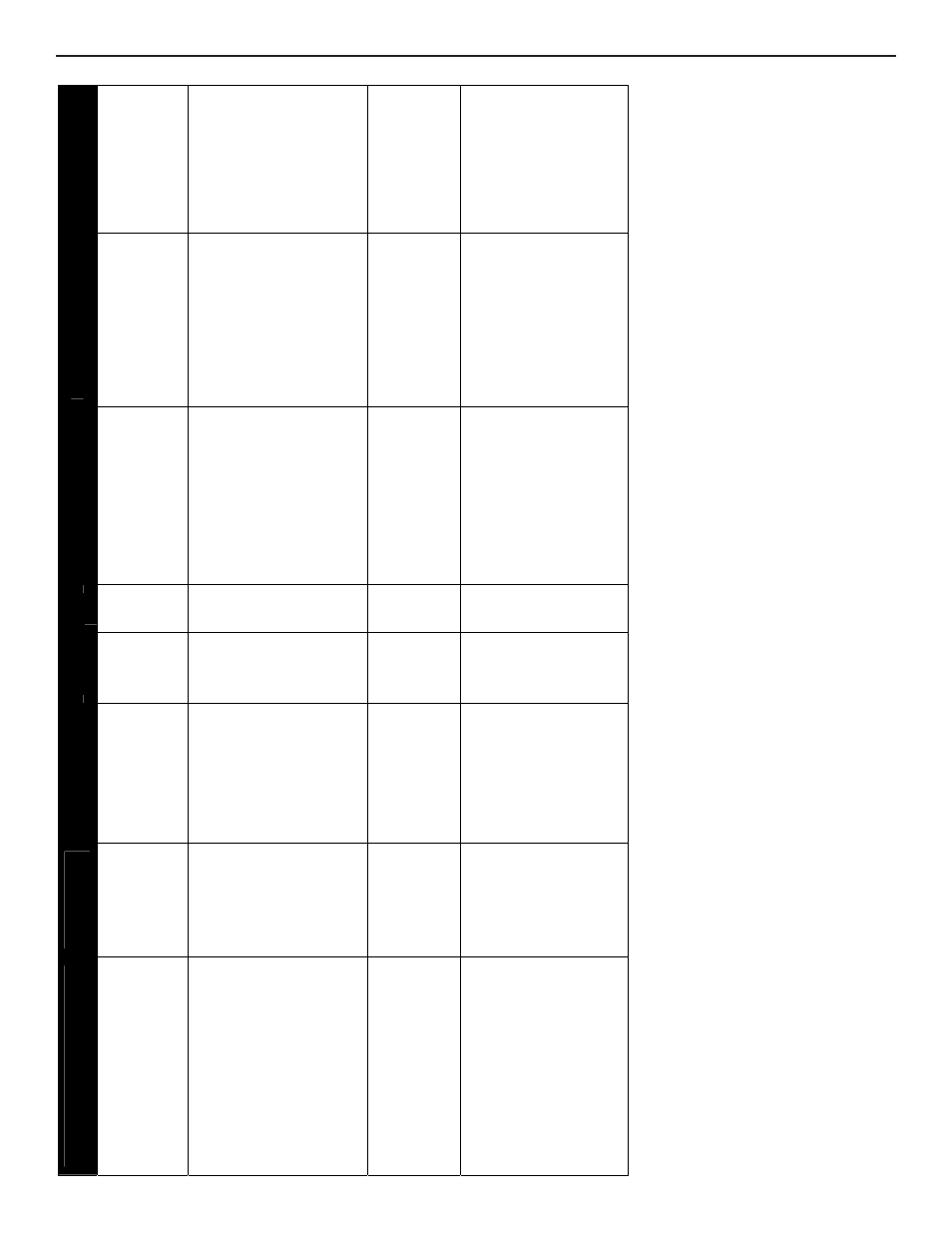

T

ROUBLESHOOTING

C

HART

55

Co

m

fo

r

tNet™

Therm

ost

at On

ly

Sym

ptom

s of A

bnor

m

al Opera

ti

on

(Leg

ac

y &

C

o

m

fort

N

et™ Therm

ost

at)

D

ia

g

no

st

ic

/St

atus

LED Codes

Fault De

scr

ipt

ion

Messa

ge

Code

P

o

ss

ib

le C

a

u

se

s

Correct

ive Action

s

No

tes

& Ca

utio

ns

x

Fur

nace fa

ils

to

opera

te on high

stage;

fur

nace

opera

tes

nor

m

ally

on low stage.

x

Int

egr

ate

d c

o

ntr

o

l m

o

du

le L

E

D

di

sp

lay

p

rovi

des

E8

err

o

r

code.

E8

x

Hi

gh

st

ag

e p

ressu

re

sw

it

ch c

irc

u

it

is c

lose

d at

sta

rt

of heating cy

cle.

x

In

du

ced

d

raft

blo

wer i

s

op

era

ti

ng.

x

Fur

nace is opera

ting

on

low

s

ta

g

e

on

ly

P

S2

CLOSED

E8

x

Hi

gh

st

ag

e p

ressu

re swi

tc

h

con

tacts

st

ickin

g

.

x

Sh

orts

in

pressu

re s

w

it

ch

ci

rcu

it

w

iri

ng.

x

Replace

high sta

g

e pr

essure

sw

it

ch.

x

Repa

ir s

h

or

t i

n

w

ir

in

g

x

T

u

rn

pow

er

O

FF pr

io

r to

repa

ir.

x

Replace pre

ssure switch

with cor

rec

t re

pla

cem

ent

par

t.

x

Fur

nace fa

ils

to

opera

te on high

stage;

fur

nace

opera

tes

nor

m

ally

on low stage.

x

Int

egr

ate

d c

o

ntr

o

l m

o

du

le L

E

D

di

sp

lay

p

rovi

des

E9

err

o

r

code.

E9

x

Hi

gh

st

ag

e p

ressu

re

sw

it

ch

ci

rc

u

it is no

t

close

d.

x

In

du

ced

d

raft

blo

wer i

s

op

era

ti

ng.

x

Fur

nace is opera

ting

on

low

s

ta

g

e

on

ly

PS

2

OPEN

E9

x

Pres

su

re sw

it

ch

h

o

se

bl

oc

ke

d

pi

nc

he

d,

or c

o

nne

cte

d

im

proper

ly

.

x

Bl

ocked

fl

ue and/

o

r

in

le

t ai

r pip

e,

bl

oc

ke

d dr

ai

n sy

stem

or w

ea

k

in

d

u

ce

d dr

aft

bl

ow

er.

x

Inc

orrec

t pre

ssure switc

h

set

p

oin

t o

r

m

al

fu

n

cti

onin

g

s

w

it

ch

conta

cts.

x

Loose or im

properly

conne

cte

d

w

iri

ng.

x

In

sp

ect

p

res

su

re s

w

itch

hos

e.

Repa

ir

/re

pla

ce if

nec

essa

ry

.

x

Ins

pe

ct f

lu

e an

d

/or

in

let a

ir

p

ipi

ng

fo

r bl

ockag

e,

p

rop

er

len

g

th,

e

lbow

s,

an

d te

rm

inat

ion.

Chec

k

drain

sy

stem

. Corre

ct

as

nece

ss

ary

.

x

Chec

k i

n

d

u

ce

d

dra

ft

bl

ow

er

perf

orm

ance. Corr

ect as

nece

ss

ary

.

x

Co

rrect

p

res

su

re s

w

itch

set

p

oin

t

or c

o

n

tac

t m

o

tio

n.

x

Tighte

n

or c

o

rrec

t wiring

co

nne

ct

ion.

x

T

u

rn

pow

er

O

FF pr

io

r to

repa

ir.

x

Replace pre

ssure switch

with cor

rec

t replac

em

ent

par

t.

x

Replace induce

d

draf

t

blower with

corr

ec

t

replacem

ent part.

x

Fur

nace

fa

ils to opera

te.

x

Int

egr

ate

d c

o

ntr

o

l m

o

du

le L

E

D

di

sp

lay

p

rovi

des

EA

err

o

r

code.

x

Com

fortNet™ therm

os

ta

t “

C

all for

Service” ic

on illum

inate

d.

x

Com

fortNet™ therm

os

ta

t scr

o

lls “

C

heck

Fur

nace” m

essa

ge.

EA

x

Pol

ari

ty

of 11

5

vo

lt

A

C

is re

ver

se

d

REVERS

ED

PLTY

EA

x

Pol

ari

ty

of 11

5

vo

lt

A

C

pow

er

to

fur

nace or

in

te

g

rat

ed m

odule

is

rever

ed.

x

Po

or un

it

groun

d

x

Revi

ew wi

ri

ng

di

ag

ram t

o

corre

ct polar

it

y

.

x

Veri

fy

p

rop

er groun

d. Co

rrect

i

f

nece

ss

ary

.

x

Chec

k a

nd c

o

rr

ect w

irin

g.

x

T

u

rn

pow

er

O

FF pr

io

r to

repa

ir.

x

Fur

nace

fa

ils to opera

te.

x

Int

egr

ate

d c

o

ntr

o

l m

o

du

le L

E

D

di

sp

lay

p

rovi

des

d

0

err

o

r c

o

de.

x

Com

fortNet™ therm

os

ta

t “

C

all for

Service” ic

on illum

inate

d.

x

Com

fortNet™ therm

os

ta

t scr

o

lls “

C

heck

Fur

nace” m

essa

ge.

d0

x

D

ata n

o

t y

et on

netw

ork.

NO NET

DATA

d0

x

Fur

nace does not

co

ntain

an

y

sh

ar

ed

d

at

a.

x

Po

pul

at

e sh

ared

d

ata s

et

us

in

g

m

e

m

o

ry

card.

x

T

u

rn

pow

er

O

FF pr

io

r to

repa

ir

x

Use m

e

m

o

ry

card for

the

spe

cif

ic m

odel.

x

Insert m

e

m

o

ry

card

BEFORE t

u

rn

ing

power

O

N

. Mem

ory

card

m

ay

be

rem

oved af

ter

dat

a i

s

loa

de

d.

x

T

u

rn

pow

er

O

FF bef

ore

rem

oving m

e

m

o

ry

ca

rd.

x

Error c

ode w

ill be cle

ared

once

data is loaded.