Ombustion – Goodman Mfg MVC95 User Manual

Page 19

19

V

ENT

/F

LUE

P

IPE

& C

OMBUSTION

A

IR

P

IPE

1

2

3

4

5

6

7

8

Standard

2 or 2 1/2

71

68

65

62

59

56

53

50

Alternate

2 or 2 1/2

58

55

52

49

46

43

40

37

2 or 2 1/2

49

46

43

40

37

34

31

28

3

71

68

65

62

59

56

53

50

2 or 2 1/2

36

33

30

27

24

21

18

15

3

57

54

51

48

45

42

39

36

Standard

3

71

68

65

62

59

56

53

50

Alternate

3

57

54

51

48

45

42

39

36

Standard

3

49

46

43

40

37

34

31

28

Alternate

3

35

32

29

26

23

20

17

14

*Maximum allowable limits listed are individual lengths for inlet & flue and NOT a combination.

1

2

3

4

5

6

7

8

2 or 2 1/2

49

46

43

40

37

34

31

28

3

71

68

65

62

59

56

53

50

2 or 2 1/2

36

33

30

27

24

21

18

15

3

57

54

51

48

45

42

39

36

2 or 2 1/2

61

58

55

52

49

46

43

40

3

71

68

65

62

59

56

53

50

2 or 2 1/2

48

45

42

39

36

33

30

27

3

57

54

51

48

45

42

39

36

Standard

3

71

68

65

62

59

56

53

50

Alternate

3

57

54

51

48

45

42

39

36

*Maximum allowable limits listed are individual lengths for inlet & flue and NOT a combination.

115,000

Number of Elbows

(1)(2)(3)(5)

Direct Vent (Dual Pipe) Maximum Allowable Length*

of Vent/Flue & Combustion Air Intake Pipe

(ft)

UPFLOW

Pipe

(4)

(inch)

Termination

Style

Unit Input

(Btu)

45,000

Standard

Alternate

70,000

90,000

115,000

COUNTERFLOW

Direct Vent (Dual Pipe) Maximum Allowable Length*

of Vent/Flue & Combustion Air Intake Pipe

(ft)

Unit Input

(Btu)

Termination

Style

Pipe

(4)

(inch)

Number of Elbows

(1)(2)(3)(5)

90,000

Standard

Alternate

70,000

Standard

Alternate

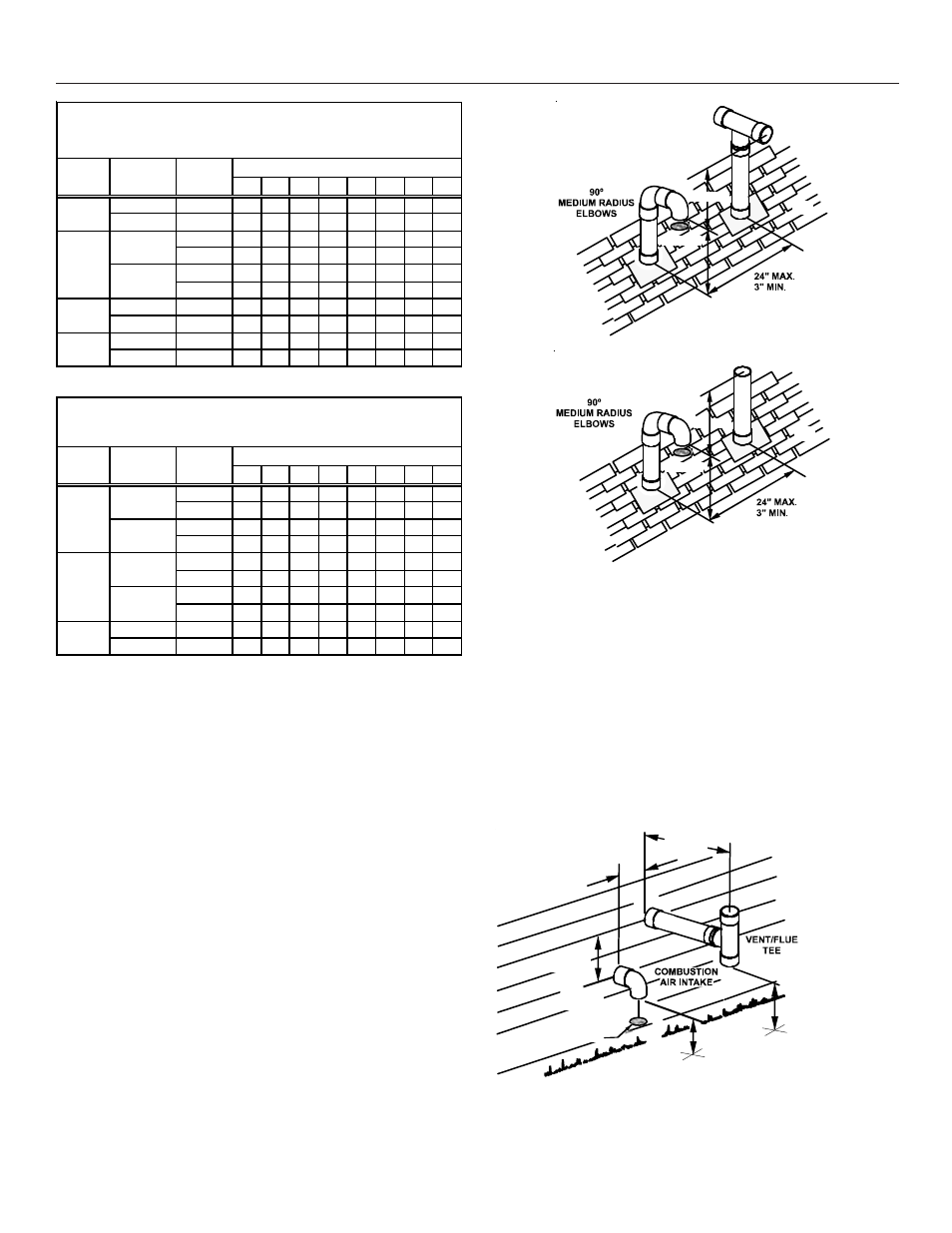

1) Elbows and/or tees used in terminations must be included when determin-

ing quantity of allowable elbows in the system.

2) Number of elbows tabulated are for each (Vent/Flue & Combustion Air

Intake) pipe.

3) Minimum requirements for each Vent/Flue & Combustion Air Intake pipe is

five (5) feet in length and one elbow/tee.

4) 2 1/2” or 3” diameter pipe can be used in place of 2” diameter pipe.

5) Increased Clearance Configurations using (2) 45 deg. Long Sweep el-

bows should be considered equivalent to one 90 deg. elbow.

Vertical pipe terminations should be as shown in the following

figure. Refer to Vent/Flue Pipe and Combustion Pipe - Termina-

tion Locations for details concerning location restrictions. The

penetrations through the roof must be sealed tight with proper

flashing such as is used with a plastic plumbing vent.

VENT/FLUE

COMBUSTION

AIR INTAKE

SCREEN

12" MIN. TO ROOF

OR HIGHEST ANTICIPATED

SNOW LEVEL

12" MIN.

TEE (OPTIONAL)

SCREEN

12" MIN. TO ROOF

OR HIGHEST ANTICIPATED

SNOW LEVEL

12" MIN.

VENT/FLUE

Vertical Terminations (Dual Pipe)

Horizontal terminations should be as shown in the following figure.

Refer to Vent/Flue Pipe and Combustion Pipe - Termination Loca-

tion for location restrictions. A 2 3/8” diameter wall penetration is

required for 2” diameter pipe. A 3” diameter hole is required for a 2

1/2” pipe and a 3 1/2” diameter hole is required for 3” diameter

pipe. To secure the pipe passing through the wall and prohibit

damage to piping connections, a coupling should be installed on

either side of the wall and solvent cemented to a pipe connecting

the two couplings. The pipe length should be the wall thickness

plus the depth of the socket fittings to be installed on the inside

and outside of the wall. The wall penetration should be sealed with

silicone caulking material.

90º

MEDIUM RADIUS

ELBOW

3" MIN

24" MAX

SCREEN

12" MIN. TO ROOF OR

HIGHEST ANTICIPATED

SNOW LEVEL

12" MIN. TO ROOF OR

HIGHEST ANTICIPATED

SNOW LEVEL

12" MIN

3" MIN

24" MAX

Standard Horizontal Terminations (Dual Pipe)