24 v, 115 v, High voltage – Goodman Mfg MVC95 User Manual

Page 29

29

E

LECTRICAL

C

ONNECTIONS

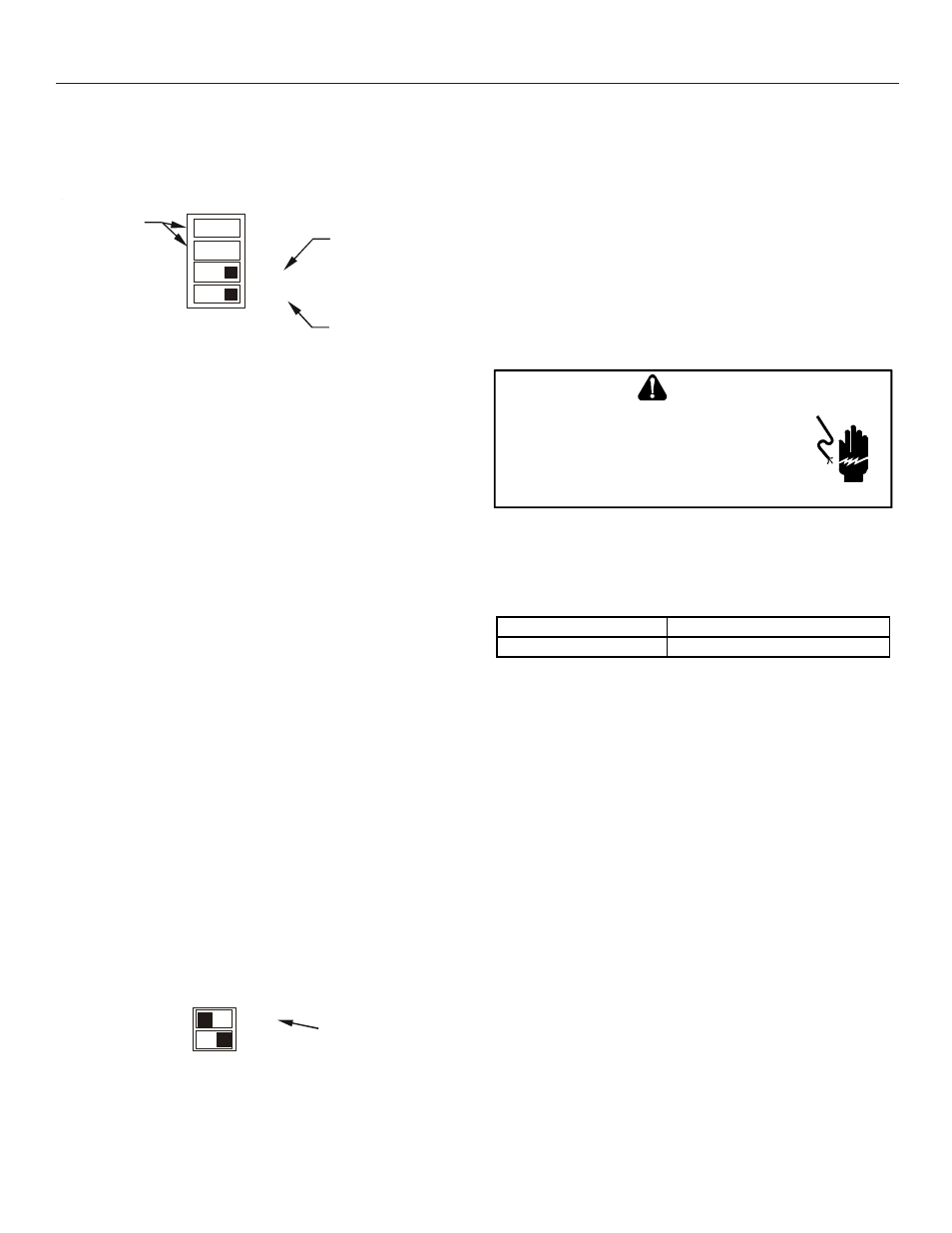

To use a single-stage thermostat, turn off power to the furnace,

move the thermostat selection DIP switch to the OFF position.

Set the desired transition time by setting the transition delay DIP

switch to the desired ON/OFF position. Turn power back on. Refer

to the following figure.

3

4

Thermostat

Stage Delay

Move to the ON position

to select two-stage

thermostat or OFF to

select single stage

thermostat

Move to the ON position

to select Auto transition

delay or OFF for 5 minute

transition delay

Heat OFF Delay

DIP Switches

ON

OFF

S1

24 V

OLT

D

EHUMIDISTAT

W

IRING

The optional usage of a dehumidistat allows the furnace’s circula-

tor blower to operate at a slightly lower speed (85% of desired

speed) during a combined thermostat call for cooling and dehumi-

distat call for dehumidification. This can be done through an inde-

pendent dehumidistat or through a thermostat’s DEHUM terminal

(if available). This lower blower speed enhances dehumidification

of the conditioned air as it passes through the AC coil. For proper

function, a dehumidistat applied to this furnace must operate on

24 VAC and utilize a switch which opens on humidity rise. Refer

to the “Thermostat Wiring Diagrams” figure for additional wir-

ing details.

To install/connect a dehumidistat:

1. Turn OFF power to furnace.

2. Secure the dehumidistat neutral wire (typically the white

lead) to the terminal marked “DEHUM” on the furnace

integrated control module.

3. Secure the dehumidistat hot wire (typically the black lead)

to the terminal marked “R” on the furnace integrated control

module.

4. Secure the dehumidistat ground wire (typically the green

lead) to the ground screw on the furnace junction box.

NOTE: Ground wire may not be present on all

dehumidistats.

5. Turn ON power to furnace.

To enable the dehumidify function on the integrated control mod-

ule, set the dehumidification ENABLE dipswitch from OFF to ON.

Once the switch is set, the dehumidify function is enabled during a

combination call for cooling (T-Stat) and dehumidification (DEHUM-

Stat).

9

10

DEHUM

Unused

Move to the ON position

to enable dehumidification

ON

OFF

S5

F

OSSIL

F

UEL

A

PPLICATIONS

This furnace can be used in conjunction with a heat pump in a

fossil fuel application. A fossil fuel application refers to a combined

gas furnace and heat pump installation which uses an outdoor

temperature sensor to determine the most cost efficient means of

heating (heat pump or gas furnace).

A heat pump thermostat with three stages of heat is required to

properly use a two-stage furnace in conjunction with a heat pump.

Refer to the fossil fuel kit installation instructions for additional

thermostat requirements.

Strictly follow the wiring guidelines in the fossil fuel kit installation

instructions. All furnace connections must be made to the furnace

two-stage integrated control module and the “FURNACE” terminal

strip on the fossil fuel control board.

115 V

OLT

L

INE

C

ONNECTION

OF

A

CCESSORIES

(H

UMIDIFIER

AND

E

LECTRONIC

A

IR

C

LEANER

)

HIGH VOLTAGE !

T

O

AVOID

PERSONAL

INJURY

OR

DEATH

DUE

TO

ELECTRICAL

SHOCK

,

DISCONNECT

ELECTRICAL

POWER

BEFORE

SERVICING

OR

CHANGING

ANY

ELECTRICAL

WIRING

.

WARNING

The furnace integrated control module is equipped with line voltage

accessory terminals for controlling power to an optional field-sup-

plied humidifier and/or electronic air cleaner.

The accessory load specifications are as follows:

Humidifier

1.0 Amp maximum at 120 VAC

Electronic Air Cleaner

1.0 Amp maximum at 120 VAC

Turn OFF power to the furnace before installing any accessories.

Follow the humidifier or air cleaner manufacturers’ instructions for

locating, mounting, grounding, and controlling these accessories.

Accessory wiring connections are to be made through the 1/4"

quick connect terminals provided on the furnace integrated control

module. The humidifier and electronic air cleaner hot terminals are

identified as HUM and EAC. The humidifier and electronic air

cleaner neutral terminals are identified as NEUTRAL. All field wir-

ing must conform to applicable codes. Connections should be

made as shown.