Warning, Upply, Iping – Goodman Mfg MVC95 User Manual

Page 34: Irculating, Ilters, Propane gas piping chart i, Propane gas piping chart ii

34

G

AS

S

UPPLY

AND

P

IPING

3/8"

1/2"

5/8"

3/4"

7/8"

1/2"

3/4"

10

730

1,700

3,200

5,300

8,300

3,200

7,500

20

500

1,100

220

3,700

5,800

2,200

4,200

30

400

920

2,000

2,900

4,700

1,800

4,000

40

370

850

1,700

2,700

4,100

1,600

3,700

50

330

770

1,500

2,400

3,700

1,500

3,400

60

300

700

1,300

2,200

3,300

1,300

3,100

80

260

610

1,200

1,900

2,900

1,200

2,600

100

220

540

1,000

1,700

2,600

1,000

2,300

125

200

490

900

1,400

2,300

900

2,100

150

190

430

830

1,300

2,100

830

1,900

175

170

400

780

1,200

1,900

770

1,700

200

160

380

730

1,100

1,800

720

1,500

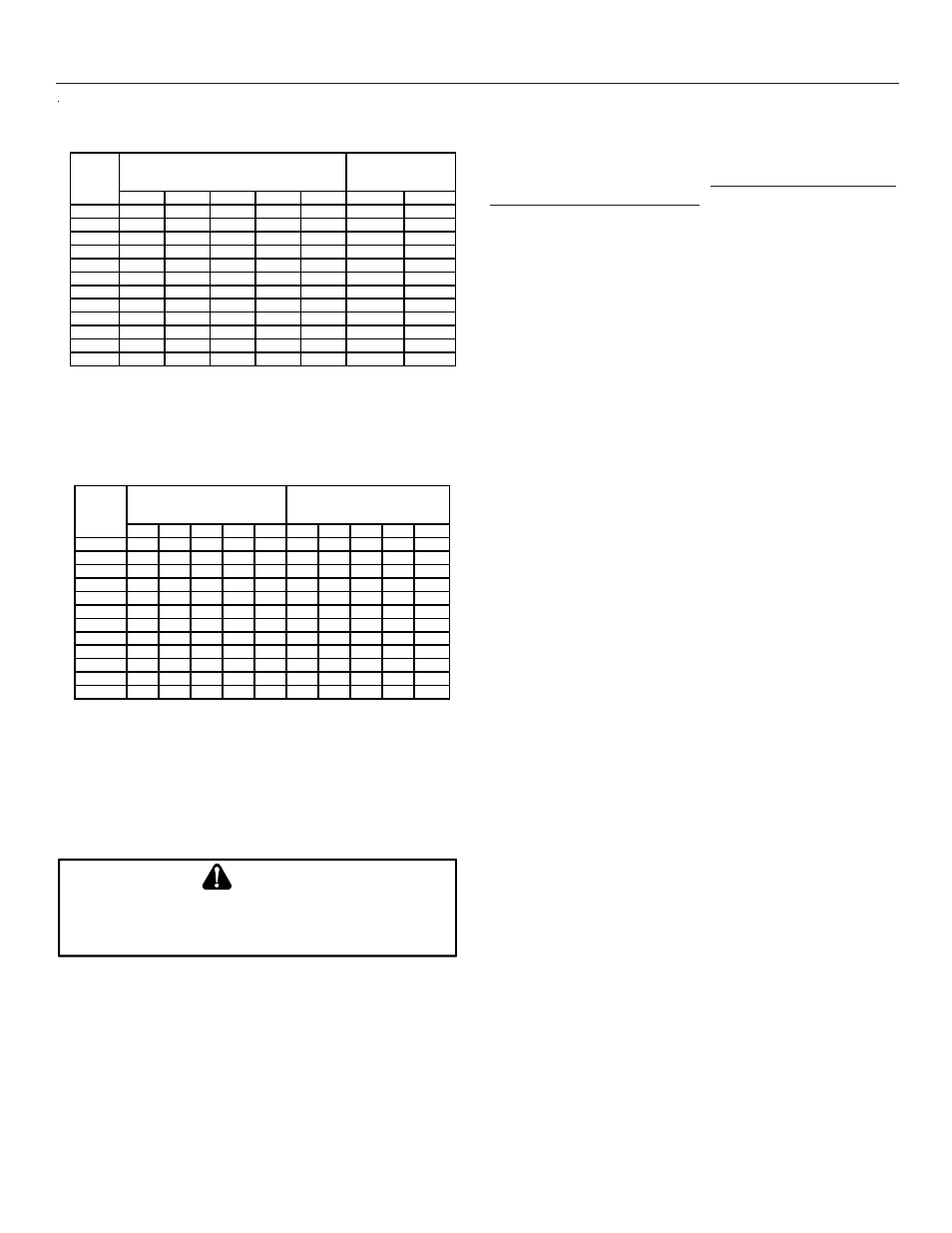

Pipe or

Tubing

Length

Feet

Tubing Size, O.D. Type L

Nominal Pipe Size

Schedule 40

Sizing Between First and Second Stage Regulator*

Maximum Propane Capacities listed are based on 2 psig pressure drop at 10 psig setting.

Capacities in 1,000 BTU/hour.

To convert to capacities at 15 psig settings - multiply by 1.130

To convert to capacities at 5 psig settings - multiply by 0.879

Propane Gas Piping Chart I

3/8"

1/2"

5/8"

3/4"

7/8"

1/2"

3/4"

1"

1-1/4" 1-1/2"

10

39

92

199

329

501

275

567

1,071 2,205 3,307

20

26

62

131

216

346

189

393

732

1,496 2,299

30

21

50

107

181

277

152

315

590

1,212 1,858

40

19

41

90

145

233

129

267

504

1,039 1,559

50

18

37

79

131

198

114

237

448

913

1,417

60

16

35

72

1,211

187

103

217

409

834

1,275

80

13

29

62

104

155

89

185

346

724

1,066

100

11

26

55

90

138

78

162

307

630

976

125

10

24

48

81

122

69

146

275

567

866

150

9

21

43

72

109

63

132

252

511

787

200

8

19

39

66

100

54

112

209

439

665

250

8

17

36

60

93

48

100

185

390

590

Tubing Size, O.D. Type L

Nominal Pipe Size

Schedule 40

Pipe or

Tubing

Length

Feet

*Data in accordance with NFPA pamphlet No. 54

Sizing Between Second or Second Stage Regulator & Appliance*

Maximum Propane Capacities listed are based on 1/2" W.C. pressure drop at 11" W.C. setting.

Capacities in 1,000 BTU/hour.

Propane Gas Piping Chart II

C

IRCULATING

A

IR

& F

ILTERS

D

UCT

WORK

- A

IR

F

LOW

N

EVER

ALLOW

THE

PRODUCTS

OF

COMBUSTION

,

INCLUDING

CARBON

MONOXIDE

,

TO

ENTER

THE

RETURN

DUCT

WORK

OR

CIRCULATION

AIR

SUPPLY

.

WARNING

Duct systems and register sizes must be properly designed for

the CFM and external static pressure rating of the furnace. Design

the ductwork in accordance with the recommended methods of

“Air Conditioning Contractors of America” Manual D.

Install the duct system in accordance with Standards of the Na-

tional Board of Fire Underwriters for the Installation of Air Condition-

ing, Warm Air Heating and Ventilating Systems. Pamphlets No.

90A and 90B.

A closed return duct system must be used, with the return duct

connected to the furnace. NOTE: Ductwork must never be at-

tached to the back of the furnace. For upflow installations requir-

ing 1800 CFM or more, use either two side returns or bottom

return or a combination of side /bottom. Flexible joints may be

used for supply and return connections to reduce noise transmis-

sion. To prevent the blower from interfering with combustion air or

draft when a central return is used, a connecting duct must be

installed between the unit and the utility room wall. Never use a

room, closet, or alcove as a return air chamber.

C

HECKING

D

UCT

S

TATIC

Refer to your furnace rating plate for the maximum ESP (ex-

ternal duct static) rating.

Total external static refers to everything external to the fur-

nace cabinet. Cooling coils, filters, ducts, grilles, registers

must all be considered when reading your total external static

pressure. The supply duct pressure must be read between

the furnace and the cooling coil. This reading is usually taken

by removing the “A” shaped block off plate from the end on the

coil; drilling a test hole in it and reinstalling the block off plate.

Take a duct static reading at the test hole. Tape up the test

hole after your test is complete. The negative pressure must

be read between the filter and the furnace blower.

Too much external static pressure will result in insufficient air

that can cause excessive temperature rise. This can cause

limit switch tripping and heat exchanger failure.

To determine total external duct static pressure, proceed as

follows;

1. With clean filters in the furnace, use a draft gauge (in-

clined manometer) to measure the static pressure of the

return duct at the inlet of the furnace. (Negative Pressure)

2. Measure the static pressure of the supply duct. (Positive

Pressure)

3. The difference between the two numbers is .4” w.c.

Example:

static reading from return duct = -.1" w.c.

static reading from supply duct = .3" w.c.

total external static pressure on this system = .4" w.c.

NOTE: Both readings may be taken simultaneously and read

directly on the manometer if so desired. If an air conditioner

coil or Electronic Air Cleaner is used in conjunction with the

furnace, the readings must also include theses components,

as shown in the following drawing.