Comfortnet™ system – Goodman Mfg MVC95 User Manual

Page 42

42

COMFORTNET™ SYSTEM

7. Select the heating speed for your model from the heating

speed chart in the Specification Sheet. The adjust setting

(already established by the cooling speed selection)

determines which set of speeds are available. The selected

speed must provide a temperature rise within the rise range

listed with the particular model.

Example:

The *MVC950704CX is set for 990 CFM on

cooling, the “ADJUST” is set to “+” (plus). The

four heating speeds available are “A Plus”, “B

Plus”, “C Plus”, and “D Plus”. “A Plus” has a

rise of 46°F for both stages which is within

the 30-60°F rise range for the *MVC950704CX.

This setting will keep electrical consumption

to a minimum. Set the “Heat” speed DIP

switches to “A”.

7

8

A

OFF

OFF

B*

ON

OFF

C

OFF

ON

D

ON

ON

Sw itch Bank : S4

Heating Speed

Taps

DIP Sw itch No.

(*Indicates f actory setting)

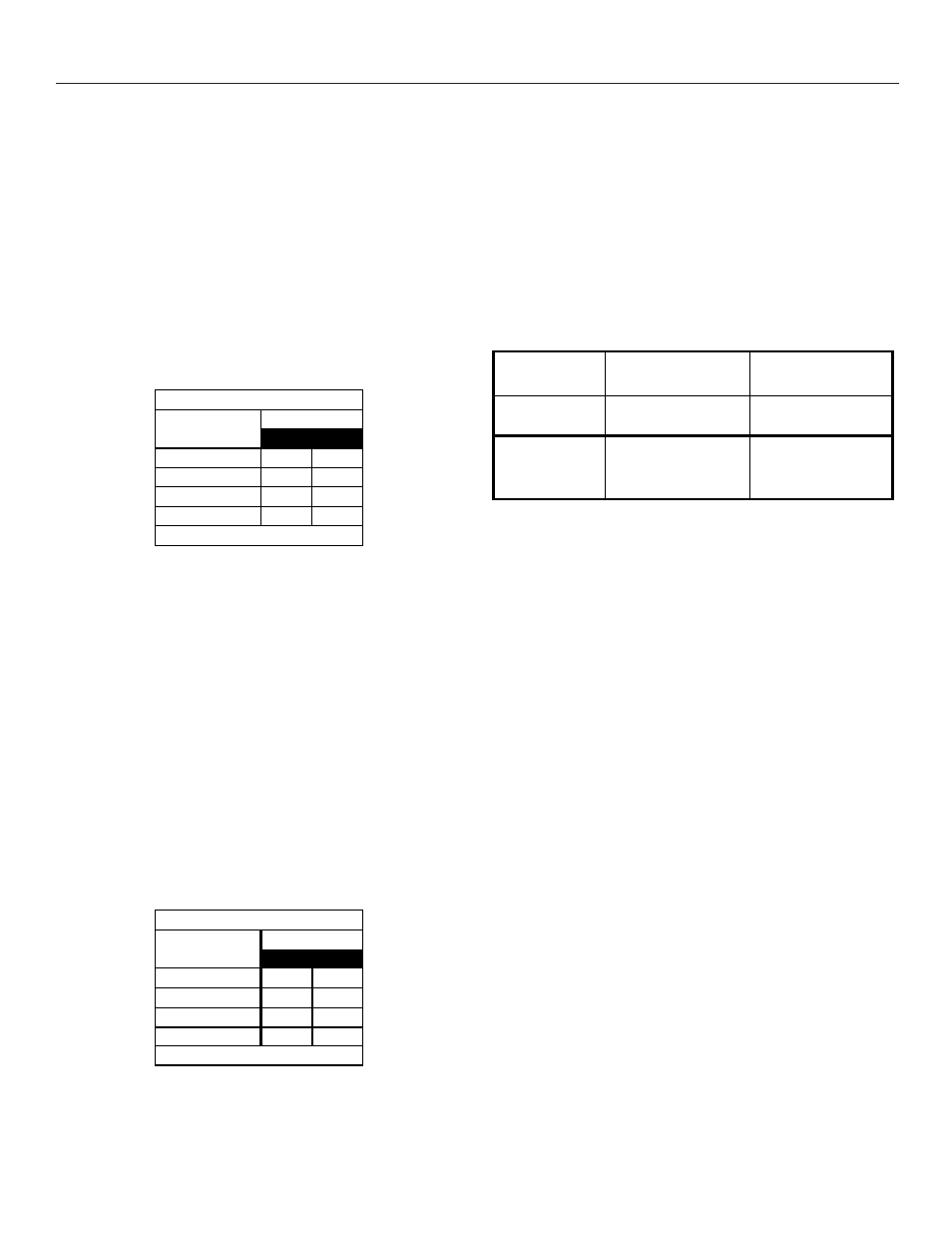

8. Select the desired “heating” speed tap by positioning

switches 7 and 8 appropriately. Refer to figure above. Verify

CFM by noting the number displayed on the dual 7-segment

LED display.

In general lower heating speeds will: reduce electrical consump-

tion, lower operating sound levels of the blower, and increase the

outlet air temperature delivered to the home. The speeds avail-

able allow the blower performance to be optimized for the particu-

lar homeowner’s needs.

B

LOWER

H

EAT

O

FF

D

ELAY

T

IMINGS

The integrated control module provides a selectable heat off delay

function. The heat off delay period may be set to 90, 120, 150, 180

seconds using the DIP switches or jumper provided on the control

module. The delay is factory shipped at 150 seconds but may be

changed to suit the installation requirements and/or homeowner

preference. Refer to the following figures for switch positions and

corresponding delay times.

1

2

90 seconds

OFF

OFF

120 seconds

ON

OFF

150 seconds*

OFF

ON

180 seconds

ON

ON

Heat OFF Delay

DIP Switch No.

Switch Bank: S1

(*Indicates factory setting)

Heat Off Delay Dipswitches

C

OMFORT

N

ET

™ S

YSTEM

O

VERVIEW

The ComfortNet system (or CT™ system) is a system that in-

cludes a ComfortNet compatible furnace and air conditioner or

heat pump with a CTK01AA thermostat. A valid ComfortNet sys-

tem could also be a compatible furnace, CTK01AA thermostat

and non-compatible, single stage air conditioner. Any other sys-

tem configurations are considered invalid ComfortNet systems and

must be connected as a traditional (or legacy) system (see Elec-

trical Connections for wiring connections). The table below com-

pares the valid CT systems.

CT compatible

Furnace

CT compatible

Air Conditioner

Full CT system

benefits and features

CT compatible

Furnace

CT compatible

Heat Pump

Full CT system

benefits and features

CT compatible

Furnace

Non-CT compatible

Single Stage

Air Conditioner

CT system

benefits and features

for furnace only

A ComfortNet heating/air conditioning system differs from a legacy/

traditional system in the manner in which the indoor unit, outdoor

unit and thermostat interact with one another. In a traditional sys-

tem, the thermostat sends commands to the indoor and outdoor

units via analog 24 VAC signals. It is a one-way communication

path in that the indoor and outdoor units typically do not return

information to the thermostat.

On the other hand, the indoor unit, outdoor unit, and thermostat

comprising a ComfortNet system “communicate” digitally with one

another. It is now a two-way communications path. The thermo-

stat still sends commands to the indoor and outdoor units. How-

ever, the thermostat may also request and receive information from

both the indoor and outdoor units. This information may be dis-

played on the CT thermostat. The indoor and outdoor units also

interact with one another. The outdoor unit may send commands

to or request information from the indoor unit. This two-way digital

communications between the thermostat and subsystems (indoor/

outdoor unit) and between subsystems is the key to unlocking the

benefits and features of the ComfortNet system.

Two-way digital communications is accomplished using only two

wires. The thermostat and subsystem controls are power with 24

VAC. Thus, a maximum of 4 wires between the equipment and

thermostat is all that is required to operate the system.

A

IRFLOW

C

ONSIDERATIONS

Airflow demands are managed differently in a fully commu-

nicating system than they are in a legacy wired system.

The system operating mode (as determined by the thermo-

stat) determines which unit calculates the system airflow

demand. If the indoor unit is responsible for determining

the airflow demand, it calculates the demand and sends it

to the ECM motor. If the outdoor unit or thermostat is

responsible for determining the demand, it calculates the