Bryant ASPAS1BBA015 User Manual

Page 43

Page 43

SECTION 2.4

DIAGNOSTIC TESTS

AC GENERATORS

3. Start the generator; let it stabilize and warm up at no-

load.

4. Connect a frequency meter across the generators AC

output leads.

5. Turn the primary adjust screw to obtain a frequency

reading of 61.5 Hertz. Turn the secondary adjust screw

to obtain a frequency of 62.5 Hz.

6. When frequency is correct at no load, check the AC

voltage reading. If voltage is incorrect, the voltage

regulator may require adjustment.

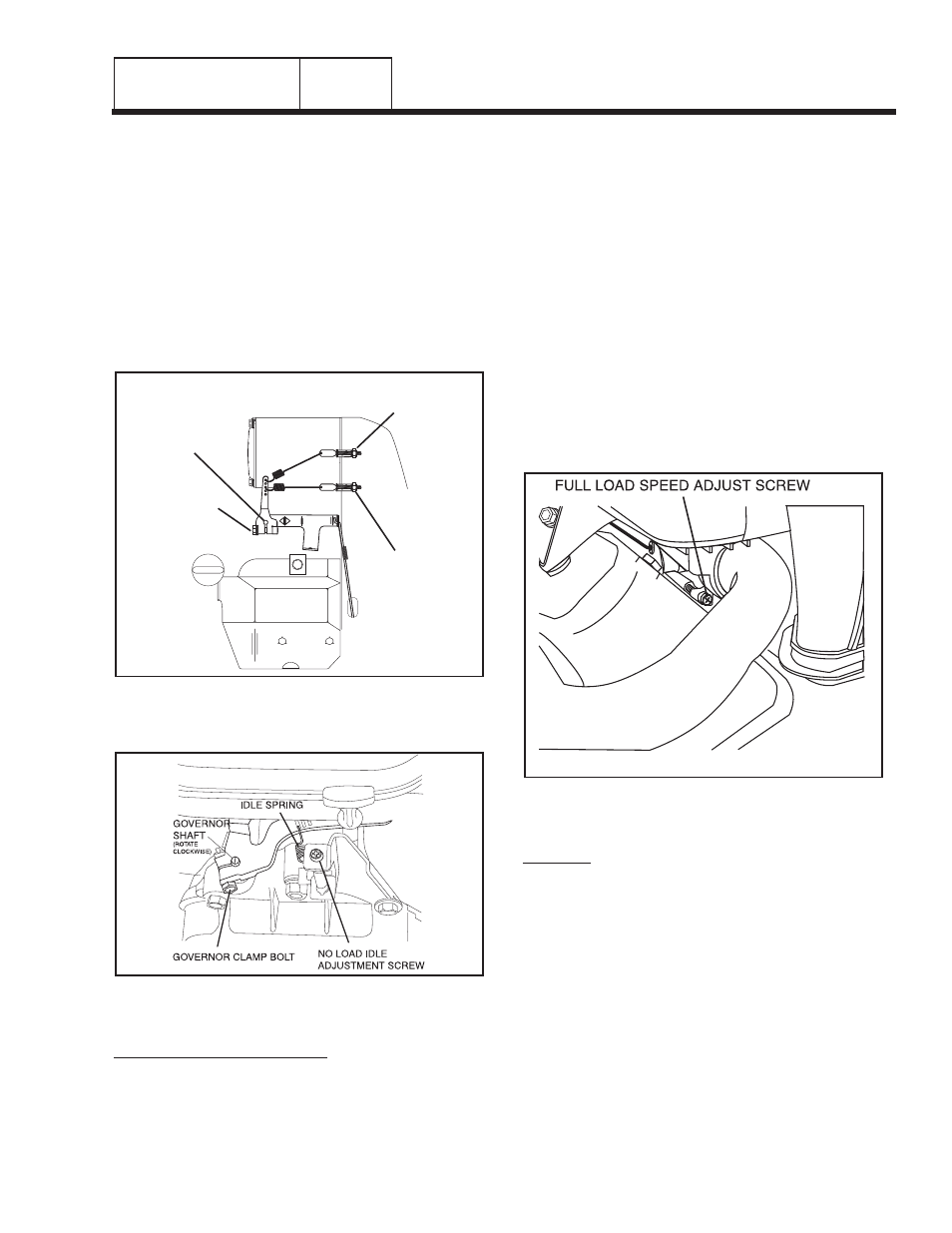

Figure 9. Engine Governor Adjustment Single

Cylinder Engines

Figure 10. Engine Governor Adjustment

V-twin Engines

PROCEDURE (12/15 KW UNITS):

1. Loosen governor clamp bolt (See Figure 10).

2. Completely remove the idle spring.

3. With governor arm at wide open throttle position, rotate

governor shaft fully clockwise. Tighten clamp bolt to 84

inch-pounds.

4. Start unit and apply full load. Use full load speed adjust

screw (Figure 11) to adjust frequency to 58 Hz.

5. Remove load, stop engine, loosen the idle adjust screw

and reconnect the idle spring.

6. Using your hand, push the governor arm to the closed

throttle position. Make sure the idle spring does not

stretch at all.

7. Restart the unit.

8. Slowly turn the idle adjust screw to adjust the no-load

idle speed to 62.5 Hz.

9. The governor is now set.

Figure 11. Full Load Speed Adjust

Screw V-twin Engines

RESULTS:

1. If, after adjusting the engine governor, frequency and

voltage are good, tests may be discontinued.

2. If frequency is now good, but voltage is high or low, go to

Test 13.

3. If engine was overspeeding, check linkage and throttle

for binding. If no governor response is indicated refer to

engine service manual.

4. If engine appears to run rough and results in low

frequency, proceed to Problem 11, Section 4.3.

GOVERNOR

SHAFT

PRIMARY

ADJUST

SCREW

GOVERNOR

CLAMP

BOLT

SECONDARY

ADJUST SCREW

PART 2