Figure 4-1. typical calibration setup -4, World class 3000, Instruction manual – Emerson Process Management 3000 User Manual

Page 64

Instruction Manual

IB-106-300NH Rev. 4.2

July 2002

4-4 Calibration

Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

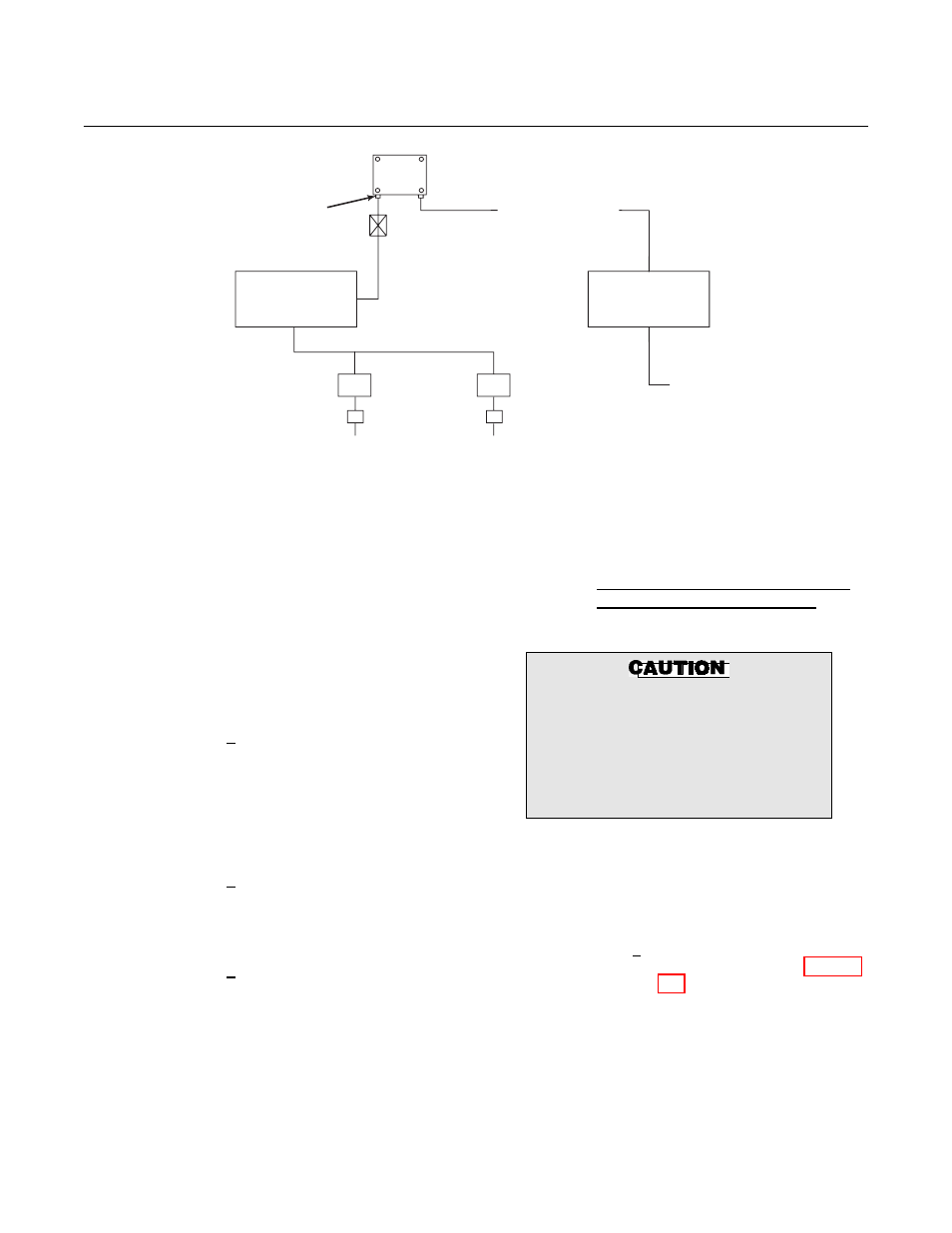

REFERENCE AIR

CONNECTION

REFERENCE

AIR

SET

FLOW METER

INSTR.

AIR

IN

LEAK TIGHT

VALVES

2 SCFH

5 SCFH

PROBE

(END VIEW)

CALIBRATE

IN-PLACE

FITTING

CHECK

VALVE

REG

0.4%

O

2

8.0%

O

2

PROBE CALIBRATION GAS FITTING

HAS A SEAL CAP WHICH MUST

BE IN PLACE AT ALL TIMES

EXCEPT DURING CALIBRATION.

NOTE:

Figure 4-1. Typical Calibration Setup

NOTE

Only set the calibration gas flowmeter

upon initial installation and after

changing the diffusion element. A

slightly lower calibration gas flow rate

may indicate a plugged diffusion

element.

2 Set the calibration gas pres-

sure regulators and the flow

meter for a flow of 5 SCFH at

20 psi (138 kPa) for both

gases. The reference air

should be flowing as in normal

operation.

3 Refer to paragraph 4-2d of

this section for Manual (Semi-

automatic) Calibration setup

and procedure using the IFT.

4 Calibration gases will be

switched on and off using the

shutoff valves.

Test Method "B" Rosemount Oxygen

Calibration Gas and Service Kit.

(a) Required Equipment

Do not use 100% nitrogen as a zero

gas. It is suggested that gas for the

zero be between 0.4% and 2.0% O

2

. Do

not use gases with hydrocarbon con-

centrations of more than 40 parts per

million. Failure to use proper gases

will result in erroneous readings.

NOTE

Ambient air is not recommended for

use as high calibration gas. An 8% O

2

balance in nitrogen is recommended

for high calibration gas.

1 Portable Rosemount Oxygen

Calibration Gas Kits (Figure

4-2), Rosemount P/N

6296A27G01, containing 8%

and 0.4% gases in a portable

carrying case with regulator,

built-in valve, hose and con-

necting adapter to the calibra-

tion gas connection.