Multiprobe calibration gas sequencer installation, Figure 2-18. mps module -22, World class 3000 – Emerson Process Management 3000 User Manual

Page 54: Instruction manual, Figure 2-18. mps module

Instruction Manual

IB-106-300NH Rev. 4.2

July 2002

2-22 Installation

Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

2-4

MULTIPROBE CALIBRATION GAS

SEQUENCER INSTALLATION

a. Mechanical

Installation

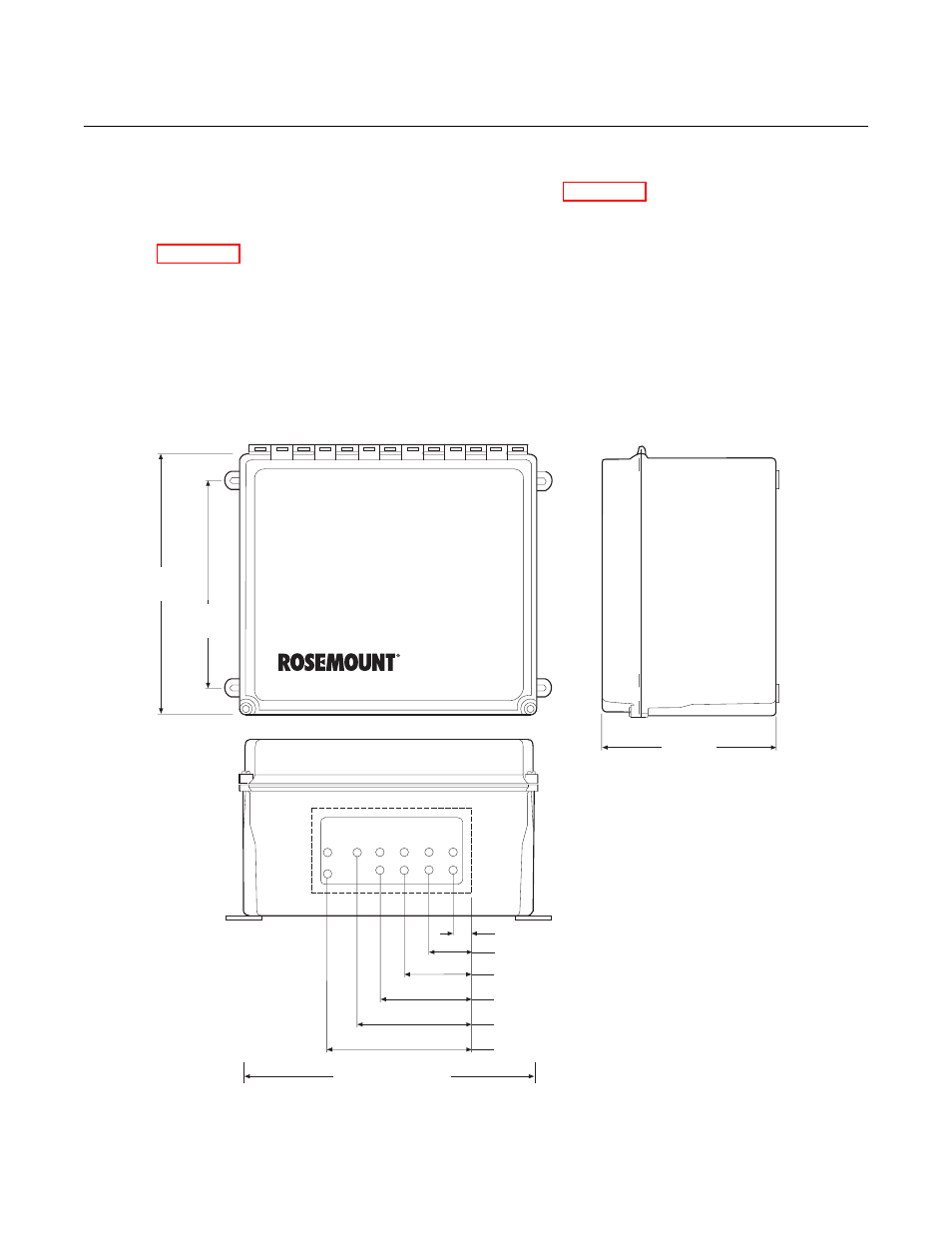

The outline drawing of the MPS module in

Figure 2-18 shows mounting centers and

clearances. The box is designed to be

mounted on a wall or bulkhead. The MPS

module should be installed no further than

300 feet (91 mz) piping distance from the

probe, and no more than 1000 feet (303 m)

cabling distance from the IFT. Install the

MPS module in a location where the ambi-

ent temperature is between -20° and 160°F

(-30° and 71°C).

b. Gas

Connections

Figure 2-19 shows the bottom of the MPS

where the gas connections are made. 1/4

inch threaded fittings are used.

1. Connect the reference air supply to

INSTR. AIR IN. The air pressure regu-

lator valve is set at the factory to 20 psi

(138 kPa). If the reference air pressure

should need readjustment, turn the

knob on the top of the valve until the

desired pressure is obtained.

2. Connect the high O

2

calibration gas to

HIGH GAS. The calibration gas pres-

sure should be set at 20 psi (138 kPa).

HIGH CAL

GAS IN

LOW CAL

GAS IN

CAL GAS

OUT

REF AIR

OUT

INSTR

AIR

REF AIR

OUT

REF AIR

OUT

REF AIR

OUT

CAL GAS

OUT

CAL GAS

OUT

CAL GAS

OUT

PROBE 1

PROBE 2

PROBE 3

PROBE4

0.84 (21.34)

27270013

1.96 (49.78)

4.21 (106.93)

3.09 (78.49)

5.25 (133.35)

5.54 (140.72)

14.00 (355.60) REF

12.00

(304.80)

12.00

(304.80)

10.00

(254.00)

NOTE: DIMENSIONS ARE IN INCHES

WITH MILLIMETERS IN

PARENTHESES.

Figure 2-18. MPS Module