World class 3000 – Emerson Process Management 3000 User Manual

Page 111

Instruction Manual

Appendix A Rev. 3.8

July 2002

Rosemount Analytical Inc. A Division of Emerson Process Management

Appendices A-13

World Class 3000

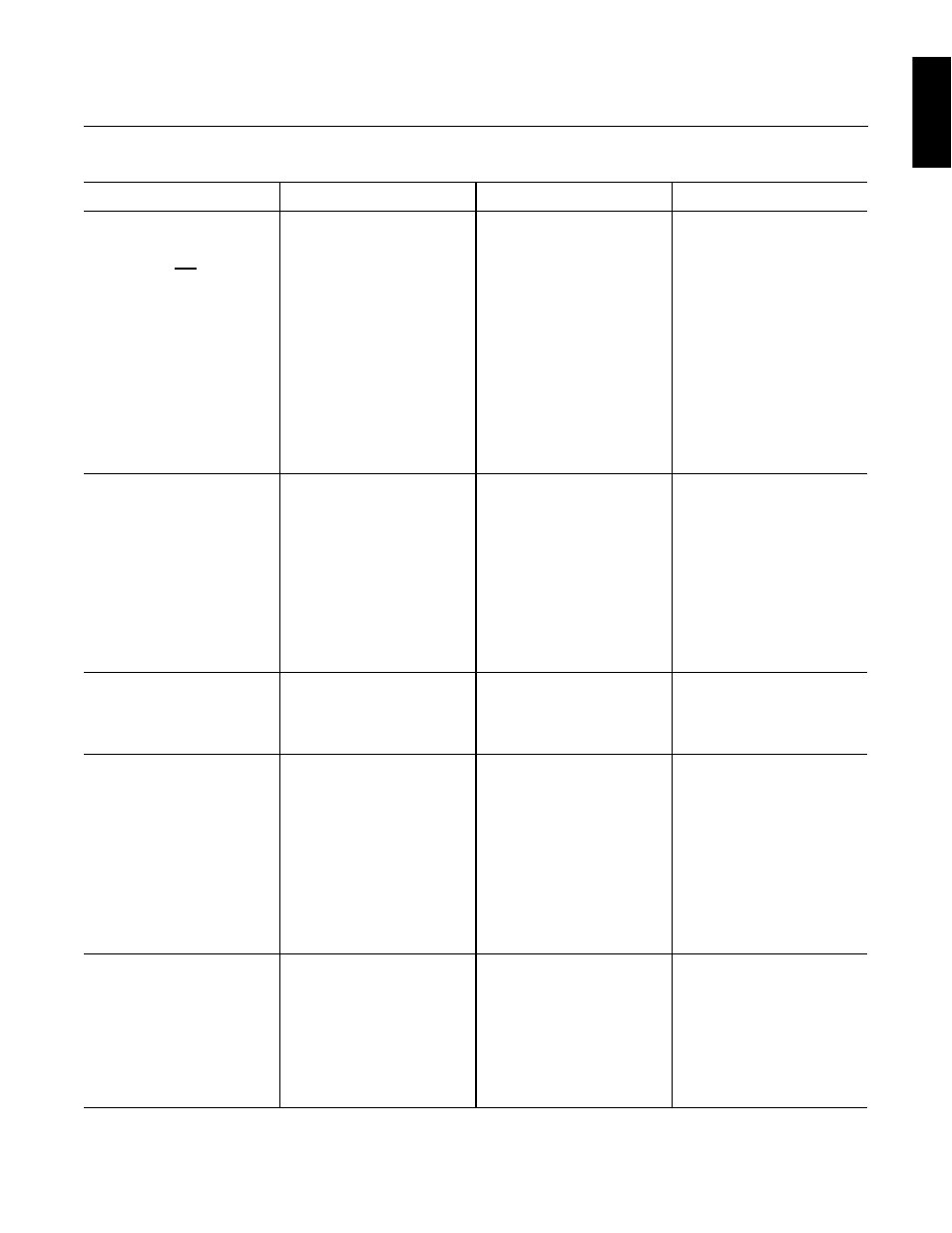

Table A-2. Fault Finding (Continued)

Symptom

Check

Fault

Remedy

2. System responds to

oxygen concentration

changes but does not

give correct indication

Recorder or remote

indicator

Calibration error

Recalibrate recorder or

indicator. Reference Re-

corder Instruction Manual.

System calibration

Calibration error

Recalibrate system.

Probe mounting and con-

dition of duct

Air ingress into duct

Stop air leaks or resite

probe.

Good response, with

incorrect indication

Cell mV input to

electronics

Failure of electronics

Check electronics

package.

Calibration gas input port

Blocked port

Clean port. If the flue gas

is condensing in the cali-

bration gas line, insulate

the back of the probe.

Make sure that the cali-

bration gas line is capped

between calibrations, or a

check valve is installed.

3. System does not give

accurate indication of

applied calibration gas

Ceramic diffusion element Diffusion element cracked,

broken, or missing

Replace diffusion element.

4. System takes a long

time to return to flue

gas value after calibra-

tion gas is turned off

Diffusion element

Plugged diffusion element Change diffusion element

or snubber diffusion

element.

Check calibration gas fit-

ting.

Leak in gasket, or calibra-

tion gas fittings or tubing.

Repair leak.

Check calibration gas

hoses or tubing.

Leak in calibration gas

hose or tubing.

Repair hose or tubing

.

Cell flange corrugated

seal.

Leaking seal.

Replace seal.

5. Probe passes calibra-

tion, but appears to

read high.

If equipped with a

n abra-

sive shield, check flange

mounting gasket.

Leaking gasket.

Replace gasket.

6. Probe passes calibra-

tion, but appears to

read low.

Flow calibration gas to the

probe until reading stabi-

lizes. Shut off calibration

gas and note the time re-

quired to return to process

gas values. Time should

be <20 sec. (<40 sec. for

hazardous area probes).

Plugged diffuser element

from high process par-

ticulate may cause a cali-

bration shift.

Replace diffuser.

A