World class 3000, Instruction manual – Emerson Process Management 3000 User Manual

Page 39

Instruction Manual

IB-106-300NH Rev. 4.2

July 2002

Rosemount Analytical Inc. A Division of Emerson Process Management

Installation 2-7

World Class 3000

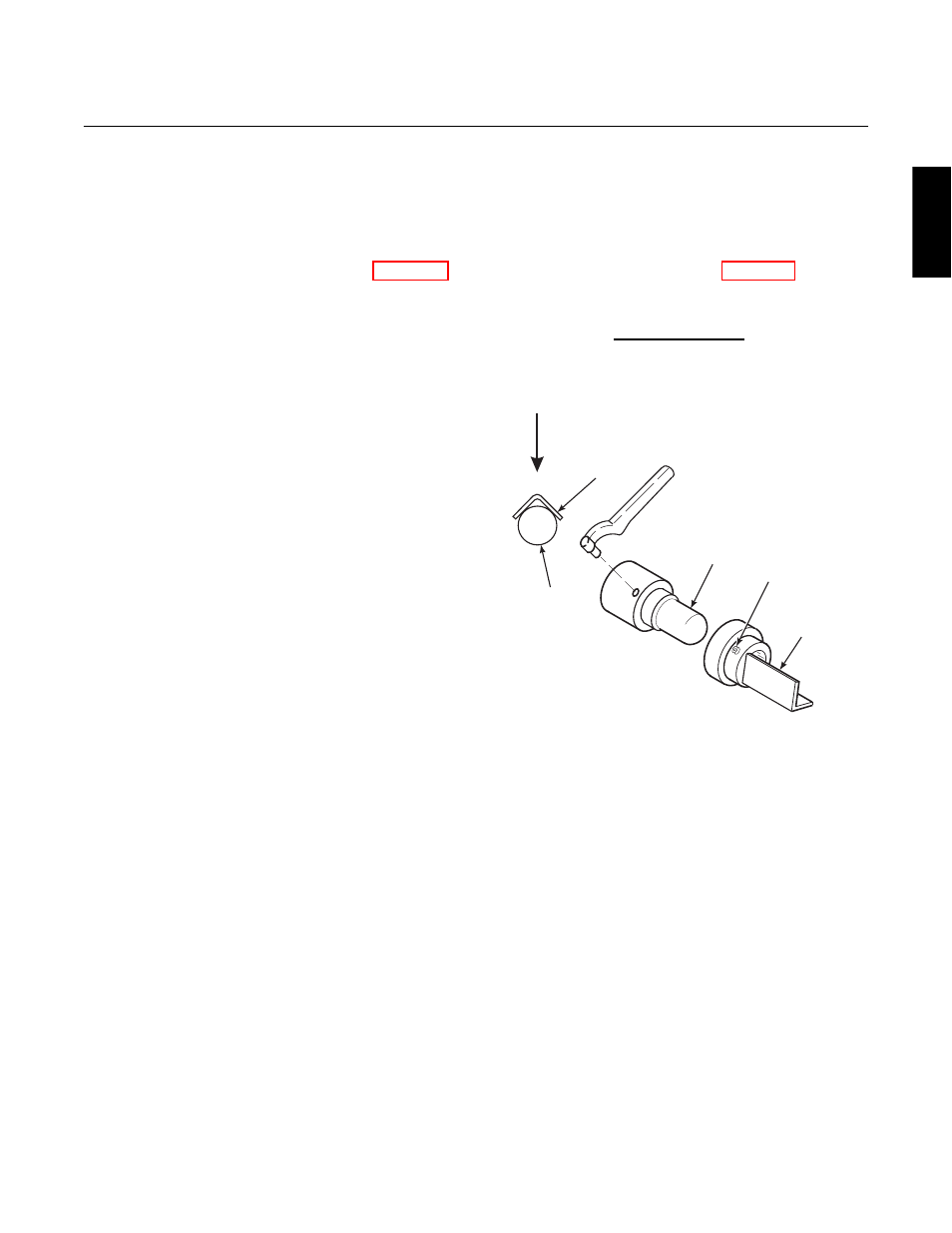

4. If using the optional ceramic diffusor

element, the vee deflector must be cor-

rectly oriented. Before inserting the

probe, check the direction of flow of the

gas in the duct. Orient the vee deflector

on the probe so that the apex points

upstream toward the flow (Figure 2-2).

This may be done by loosening the

setscrews, and rotating the vee de-

flector to the desired position.

Retighten the setscrews.

5. In horizontal installations, the probe

junction box should be oriented so that

the system cable drops vertically from

the probe junction box. In a vertical in-

stallation, the system cable can be ori-

ented in any direction.

6. If the system has an abrasive shield,

check the dust seal packings. The

joints in the two packings must be

staggered 180°. Also, make sure that

the packings are in the hub grooves as

the probe slides into the 15° forcing

cone in the abrasive shield.

NOTE

If process temperatures will exceed

392°F (200°C), use anti-seize com-

pound on stud threads to ease future

removal of probe.

7. Insert probe through the opening in the

mounting flange and bolt the unit to the

flange. When probe lengths selected

are 9 or 12 ft (2.75 or 3.66 m), special

brackets are supplied to provide addi-

tional support for the probe inside the

flue or stack. See Figure 2-1, sheet 5.

NOTE

Probe Installation

To maintain CE compliance, ensure

there is a good connection between

the chassis of the probe and earth.

VEE

DEFLECTOR

VEE

DEFLECTOR

DIFFUSION

ELEMENT

SETSCREW

FILTER

GAS FLOW

DIRECTION

APEX

624017

Figure 2-2. Orienting the Optional Vee Deflector

2