Ethernet communication module dvpen01-sl – Delta Electronics Ethernet Communication Module DVPEN01-SL User Manual

Page 51

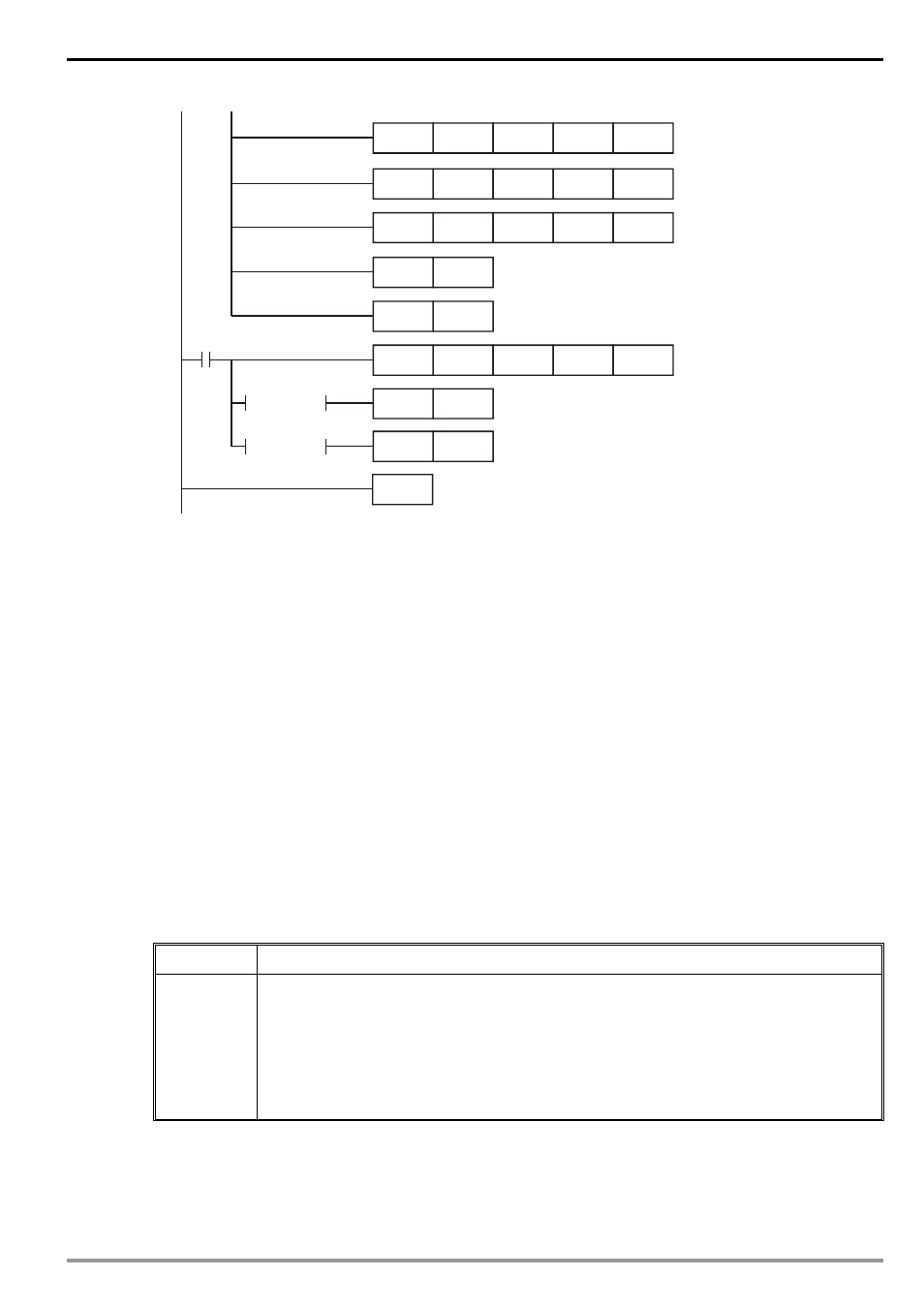

Ethernet Communication Module DVPEN01-SL

DVP-PLC Application Manual

49

END

SET

M2

M1

RST

K100

K1

M2

K14

D14

RST

M2

RST

M2

= D14 K2

= D14 K3

FROM

K100

K1

TOP

K100

TOP

K1

K1

K0

K14

K13

K100

TOP

K1

K86

H1064

Explanations:

•

The data exchange will be executed every one second.

•

Write “0” into CR#28, and PLC_B will use CR#25 ~ CR#26 as the IP address of the destination

PLC.

•

Write the IP address of PLC_A into CR#25 and CR#26. The first two IP codes (192.168 =

H’C0A8) should be written into CR#26, and the last two IP codes (0.4 = H’0004) into CR#25.

•

Write the Modbus address of D0 (H’1000) in PLC_A into CR#81 and CR#84.

•

Write the Modbus address of D100 (register of RTC) (H’1064) into CR#86.

•

Write the number of registers K7 into CR#85.

•

Write “1” into CR#13 to start the data exchange.

•

CR#14 = 2 refers to successful execution. CR#14 = 3 refers to failed execution.

•

Once the data exchange is successful, the values in D1313 ~ D1318 in PLC_B will be written into

D0 ~ D6 of PLC_A.

6.12 Application of Modbus TCP Master (1)

Application

Compiling Modbus instrcution by PLC_B, making Y0 of PLC_A flashing

Network

requirement

(1) Adopting static IP.

(2) IP of PLC_A: 192.168.0.4

(3) IP of PLC_B: 192.168.0.5

(4) Update from PLC_B to PLC_A

(5) Use Modbus instrcution 050500FF00 to set “On” Y0.

(6) Use Modbus instrcution 0505000000 to set “Off” Y0.

(7) Y0 goes between On/Off once every one second.

1. See 6.1 for how to set up the communication.

2. Compile the ladder diagram in the MPU and download it to PLC_B. See below for the program design.

We do not need to write any corresponding ladder diagram into PLC_A.