Actual level set point set up, Calculated set point set up, Output relay wiring – SOR Multi Point RF Level Switch User Manual

Page 26

26/36

Form 677 (05.13) ©SOR Inc.

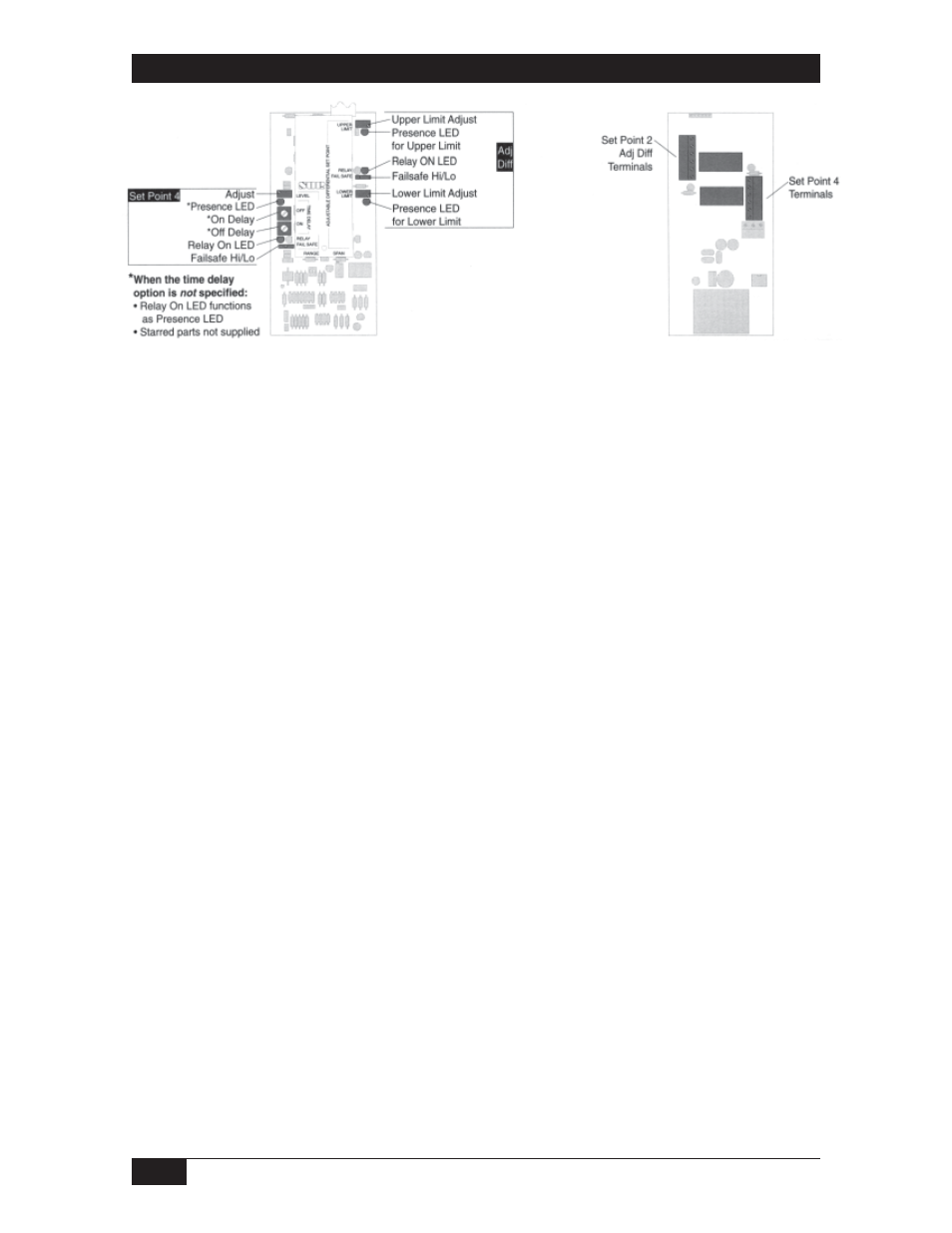

Model 667 Set Point Set up and Output Wiring

Actual Level set point set up

Continued from page 8.

Process level must be steady at the upper limit of the adjustable differential set point. Turn

upper limit (pump up) adjust pot CW until its Presence LED lights and then CCW to the

point where the LED goes off. Slowly cycle the Presence LED on and off as required to find

the precise threshold at which the LED goes off.

Lower process level to lower limit of the adjustable differential set point. Use the lower

limit (pump down) adjust pot to find the threshold of its Presence LED.

Lower process level to set point 4 level. Use the set point 4 adjust pot to find the

threshold of its Presence LED.

Continue with output wiring from the bottom of this page.

Calculated set point set up

Continued from page 9.

The pf value from worksheet line 11 should still be injected. Turn the upper limit (pump up)

adjust pot CW until its Presence LED lights and then CCW to the point where the LED goes

off. Slowly cycle the LED on and off as required to find the precise threshold at which the

LED goes off.

Inject the pf value from line 15 of the worksheet. Use the lower limit (pump down)

adjust pot to find the threshold of its Presence LED.

Inject the pf value from line 17 of the worksheet. Use the set point 4 adjust pot to find

the threshold of its Presence LED.

Disconnect the probe lead and the probe ground lead from the capacitor substitution box

terminals. Connect the probe lead and the probe ground lead to the probe. Continue with

output wiring from the right side of this page.

Output Relay Wiring

Before connecting output relays to external devices, determine which failsafe mode is best

suited for each sensing level. Refer to the continuity chart below when connecting to relay

terminal strips.