SOR Mini-Hermet User Manual

Mini-hermet pressure switches, General instructions

Form 168 (05.13) ©SOR Inc.

1/8

General Instructions

Design and

specifications are

subject to change

without notice.

For latest revision, go to

www.sorinc.com

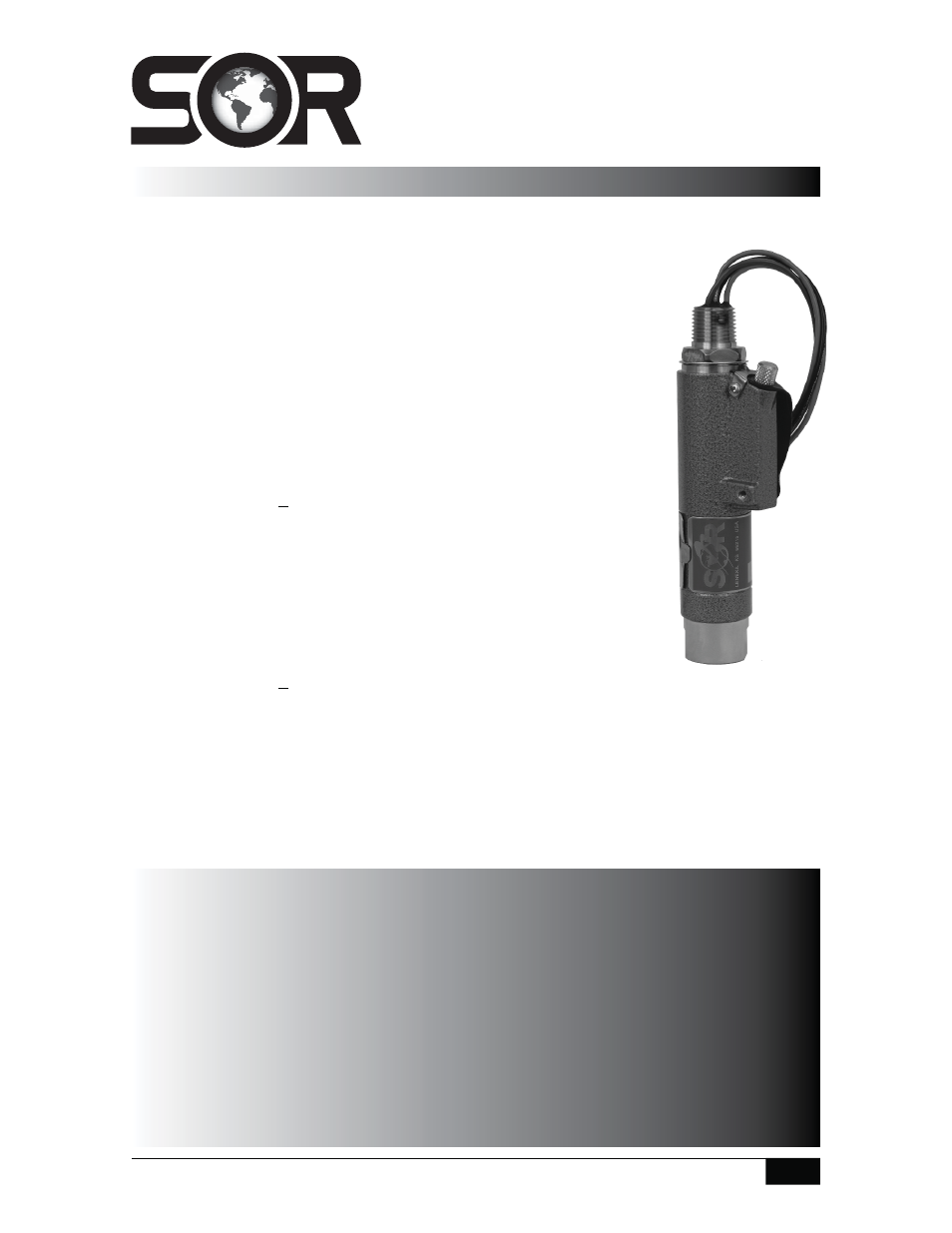

Mini-Hermet Pressure Switches

with Hermetically Sealed

Electrical Switching Elements

Table of Contents

Installation .......................................2

Process Connection ............................2

Electrical Connection ...........................3

SIL Installation ..................................4

Calibration .......................................4

Special Conditions ..............................5

Dimensions ......................................5

General Information for ATEX .................6

ATEX Marking Materials .......................7

Declaration of Conformity .....................8

Registered Quality System to ISO 9001

These instructions cover installation, process connection, electrical connection and

calibration of the SOR

®

Mini-Hermet explosion proof pressure switches.

The switching element is hermetically sealed in an explosion proof capsule

that is UL Listed and CSA Certified for hazardous locations Class I,

Groups A, B, C & D; Class II, Groups E, F & G; Divisions 1 & 2 and

SAA Approved for Ex s IIC T6 IP65 Class 1, Zone 1. When certain

options are ordered, the Pressure Switch may be ATEX Certified

EEx d IIC or UL Listed and CSA Certified Class I, Groups A, B, C & D;

Class II, Groups E, F & G; Divisions 1 & 2.

Static O-Ring Type (prefaced by 1, 5, 6, 9, 10 or 56)

Typical Model No. 6AG-EF3-N4-C1A

The static o-ring type pressure switch with optional wetted parts is

suitable for a wide variety of process applications. This type is not

recommended for high-pressure fluid power applications where

high shock pressure and high cycle rates are expected. Use SOR

pivot seal type for fluid power applications.

Pivot Seal Type (prefaced by 2 or 3)

Typical Model No. 3AH-EF45-P1-C1A

The pivot seal type pressure switch is generally suitable for fluid power hydraulic

applications where high shock pressures and high cycle rates are expected and where

only normally industrial clean hydraulic fluid is used. Use static o-ring type for other

process applications.

NOTE: If you suspect that a product is defective, contact the factory or the SOR Representative

in your area for a return authorization number (RMA). This product should only be installed by

trained and competent personnel.