SOR High Static Operation User Manual

102 differential pressure switch

Form 420 (01.13) ©SOR Inc.

1/8

These instructions provide information for installation, electrical connection, process con-

nection and calibration of 102 Differential Pressure Switches.

Process pressure is sensed by a piston assembly. The piston responds to differential

pressure and moves a lever connected to a torsionally stiff cross-shaft. One end of the

cross-shaft is connected to a lever that is biased by the range spring. The other end has a

lever that actuates (deactuates) an electrical switching element.

102

Differential Pressure Switch

General Instructions

Registered Quality System to ISO 9001

Design and

specifications are

subject to change

without notice.

For latest revision, go to

www.sorinc.com

Table of Contents

Installation .......................................2

SIL Installation ..................................2

Process Connection ............................2

Electrical Connection ...........................2

Special Conditions ..............................3

Calibration .......................................4

Dimensions ......................................5

ATEX General Information .....................6

Declaration of Conformity .....................7

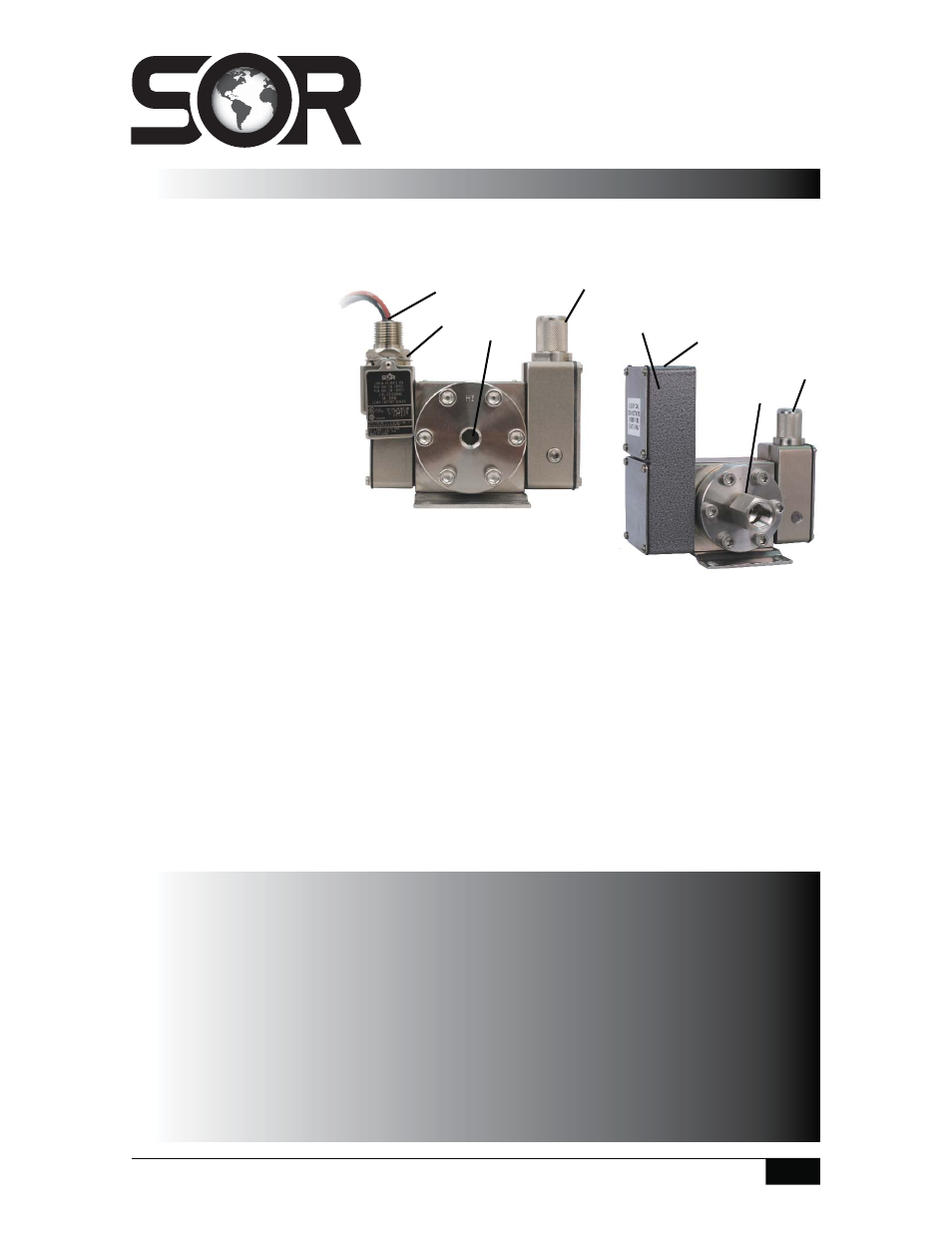

Knurled cap over set

point adjustment

High side process

connection 1/4 NPT(F)

[1/2” NPT(F) optional]

Hermetically sealed

switching element

capsule with 18 AWG

wire leads, 18” (45.7

cm) in length

1/2” NPT(M) electrical

Explosion Proof – AD Housing

ATEX Certified EEx d IIC - CL Accessory

Weathertight – W1 Housing

conduit connection

3/4” NPT (F) electrical conduit connection

Weathertight switching element housing (terminal block under cover)

NOTE: If you suspect that a product is defective, contact the factory or the SOR

®

Representative

in your area for a return authorization number (RMA). This product should only be installed by

trained and competent personnel.

PT(F)

onal]

d

AWG

5.7

rical

under cover)