SOR 534HS Two-Wire Pressure Transmitters User Manual

SOR Sensors

Form 953 (03.13) ©SOR Inc.

1/12

These instructions provide information for installation, process connection,

electrical connection and field calibration of SOR

®

534HS Pressure

Transmitters. The 534HS Pressure Transmitter consists of a field proven

thin film pressure transducer and a reliable electronic circuit. The

housing features external adjustments and stainless steel construction.

The 534HS is capable of powering long cable lengths. See Formulas

for maximum loop resistance formulas.

NOTE: This instrument is non-repairable. If you suspect that it is defective,

contact the factory or the SOR representative in your area for a return

authorization number.

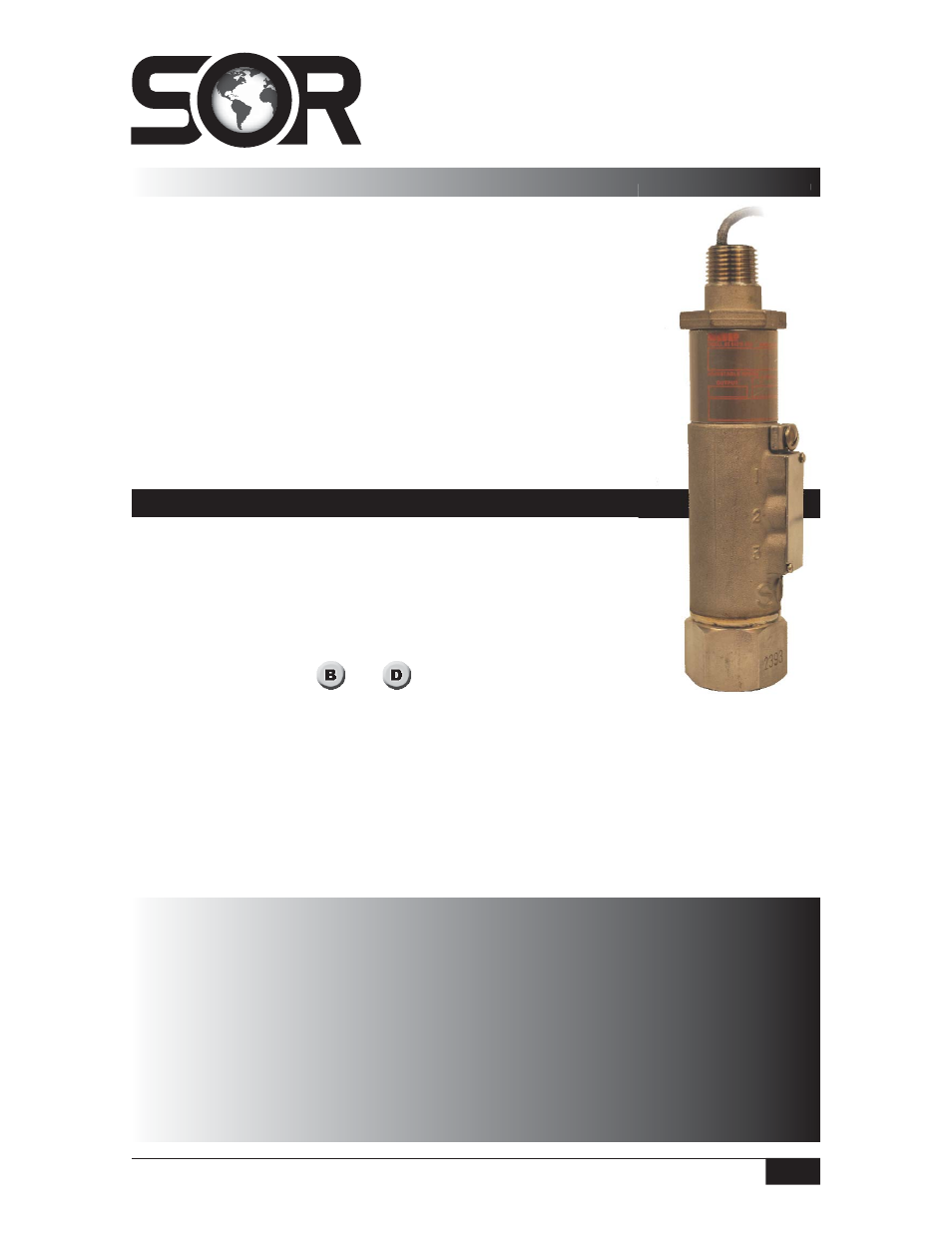

534HS

Pressure Transmitter

General Instructions

Registered Quality System to ISO 9001

Design and

specifications are

subject to change

without notice.

For latest revision, go to

www.sorinc.com

NOTE: If you suspect that a product is defective, contact the factory or the SOR Representative

in your area for a return authorization number (RMA). This product should only be installed by

trained and competent personnel.

Table of Contents

Installation .......................................1

Wiring 534HS-TN ...............................2

Calibration .......................................2

Dimensions ......................................4

Wiring 534HS-VN ...............................4

Calibration .......................................5

Dimensions ......................................7

Control Drawings ...........................8-10

Installation

Ensure that wiring conforms to all applicable local and national

electrical codes and install unit(s) according to relevant national

and local safety codes.

Normally, line mounting provides adequate support for the instrument.

When the installation is complete, the external adjustments must be

accessible. (See Figures

and

) Determine whether the process

connection or the electrical connection will be made first.

ection,

ven

on.

s

ve,

neral Instructions

ent.

e

ess

Making the Process Connection First

The process connection is threaded onto a fitting within an adequately supported process

piping system. Use two open end wrenches when connecting the pressure port to a