Parr Instrument 6200 User Manual

Page 32

33

6200

Calorimeter Operating Instruction Manual

Corrosive

Samples

5

The 1108 Oxygen Bomb is made

of a corrosion resistant alloy

designed to withstand the corrosive

mixture of sulfuric and nitric acids

produced in normal fuel testing

operations. Samples containing chlorine

and particular samples containing more

than 20 mg of chlorine samples with

high sulfur contents will greatly

accelerate corrosion of the bomb. An

alternate 1108CL Bomb is available

constructed of an alloy selected to

specifically resist the corrosive effects of

samples with high chlorine or chloride.

While no material will offer complete

corrosion resistance to these samples, the

1108CL Bomb offers significantly enhanced

corrosion resistance for this service.

The 1108 and 1108CL Bombs used

in the 6200 Calorimeter have been

designed to provide highly automated

testing of routine samples. Materials

which release large volumes of gas which

detonate with explosive force or burn with

unusually high energy levels, should not be

tested with these bombs.

Rather, they should be tested in a model

1104 High Pressure Oxygen Bomb

designed specifically for these types of

samples

.

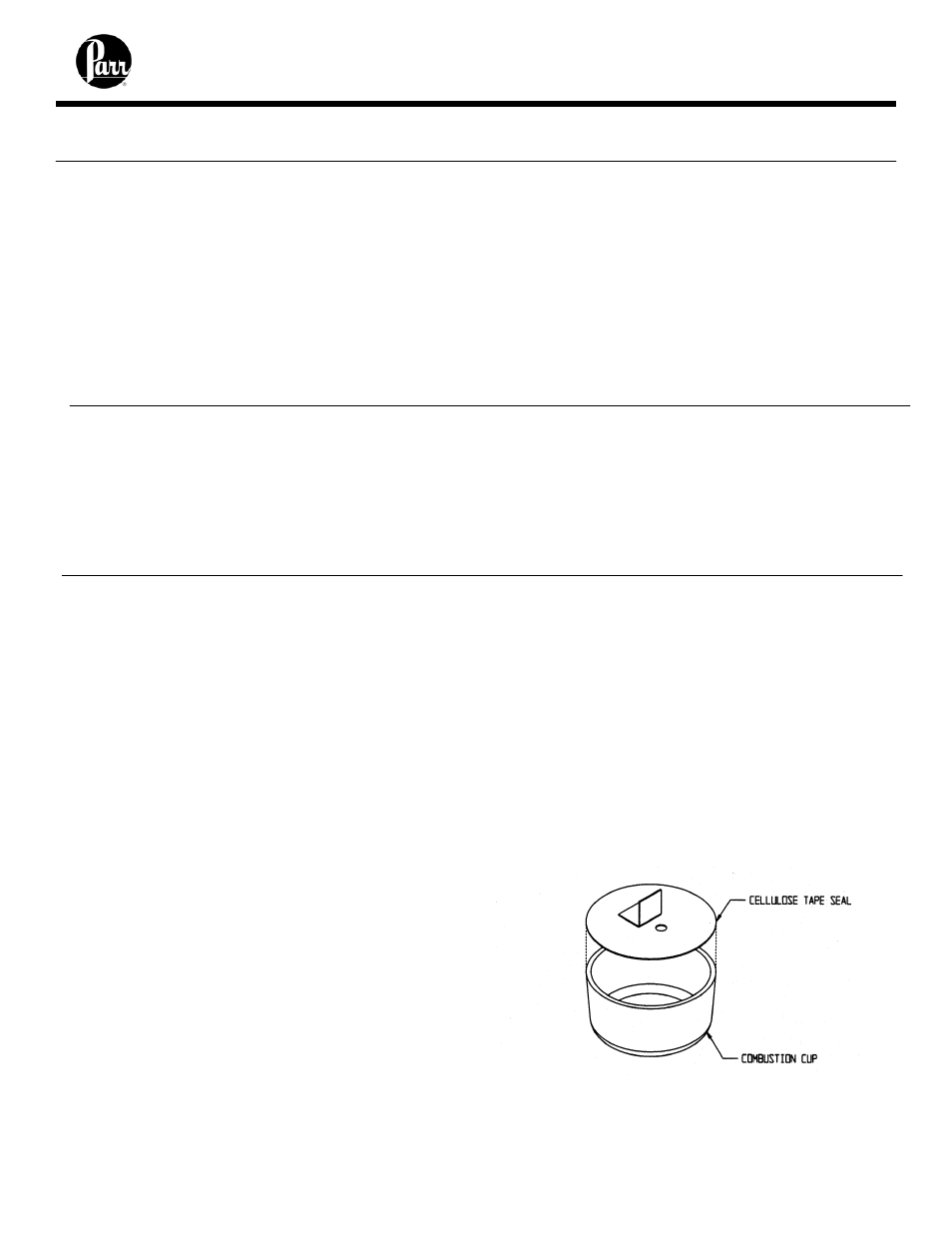

Volatile samples can be handled

in a Parr 43A6 Platinum Capsule with

a spun rim, or in a Parr 43AS Alloy

Capsule which has a sturdy wall with

a flat top rim. These holders can be sealed

with a disc of plastic adhesive tape

prepared by stretching tape across the top

of the cup and trimming the excess with a

sharp knife. The seal obtained after

pressing this disc firmly against the rim of

the cup with a flat blade will be adequate for

most volatile samples.

The tape used for

this purpose should be free of chlorine and

as low in sulfur as possible. Borden Mystic

Tape, No. M-169-C or 3M Transparent

Tape, No. 610, are recommended for this

purpose. The 3M Transparent Tape can be

ordered through Parr, Part No. 517A.

The weight of the tape disc must be

determined separately and a correction

applied for any elements in the tape which

might interfere with the

determination. This can be done by running

a blank test with tape alone using a sample

weighing 1.0 gram. The compensation for

heat of tape may be done through the spike

option; see Spike Controls, Heat of

Combustion of Spike. The heat of

combustion of the 517A tape is

approximately 6300 cal/gram.

Note:

Tape should always be stored in a

sealed container to minimize changes in

its moisture and solvent content

.

Explosives

and High

Energy

Fuels

Volatile

Sample

Holders

Figure 5-7

Combustion Capsule

with Adhesive Tape Seal

5-7