Linknet – LINK Systems LinkNet I User Manual

Page 24

LinkNet

4.2

manual rev 2.1 March 25, 1999

minute poll is multiplied by the remaining parts to

be produced as given by the part counter to get an

estimated completion time. Note that if the part

counter is turned off or the average production rate

is 0, this field will display “?:??” because there is not

enough information to calculate a completion time.

If the last 10 minute poll production rate is 0, the 15

second average strokes per minute is used instead.

Pk Tons

-

The peak forward tonnage of the

last stroke if a tonnage monitor is present.

Each of these column headings can be clicked on

to sort the machines by the heading data. For

instance, if the “Mach #” heading is clicked, the

machine will be sorted by ascending machine

number. If the heading is clicked again, the

machines will be sorted by descending machine

number. Likewise, if the “Pk Tons” heading is

clicked, the machines will be sorted by ascending

tonnage and so on for each column. A small arrow

appears in the column heading that is being used to

sort and points up for ascending order and down for

descending order.

4.2

Detail Dialogs

Additional detail can be viewed on a machine by

machine basis by double clicking anywhere on the

row for a machine in the overview window. This

brings up a tabbed dialog with several different

sections of information. Each section is a tab at the

top of the dialog box.

4.2.1

Counter Detail

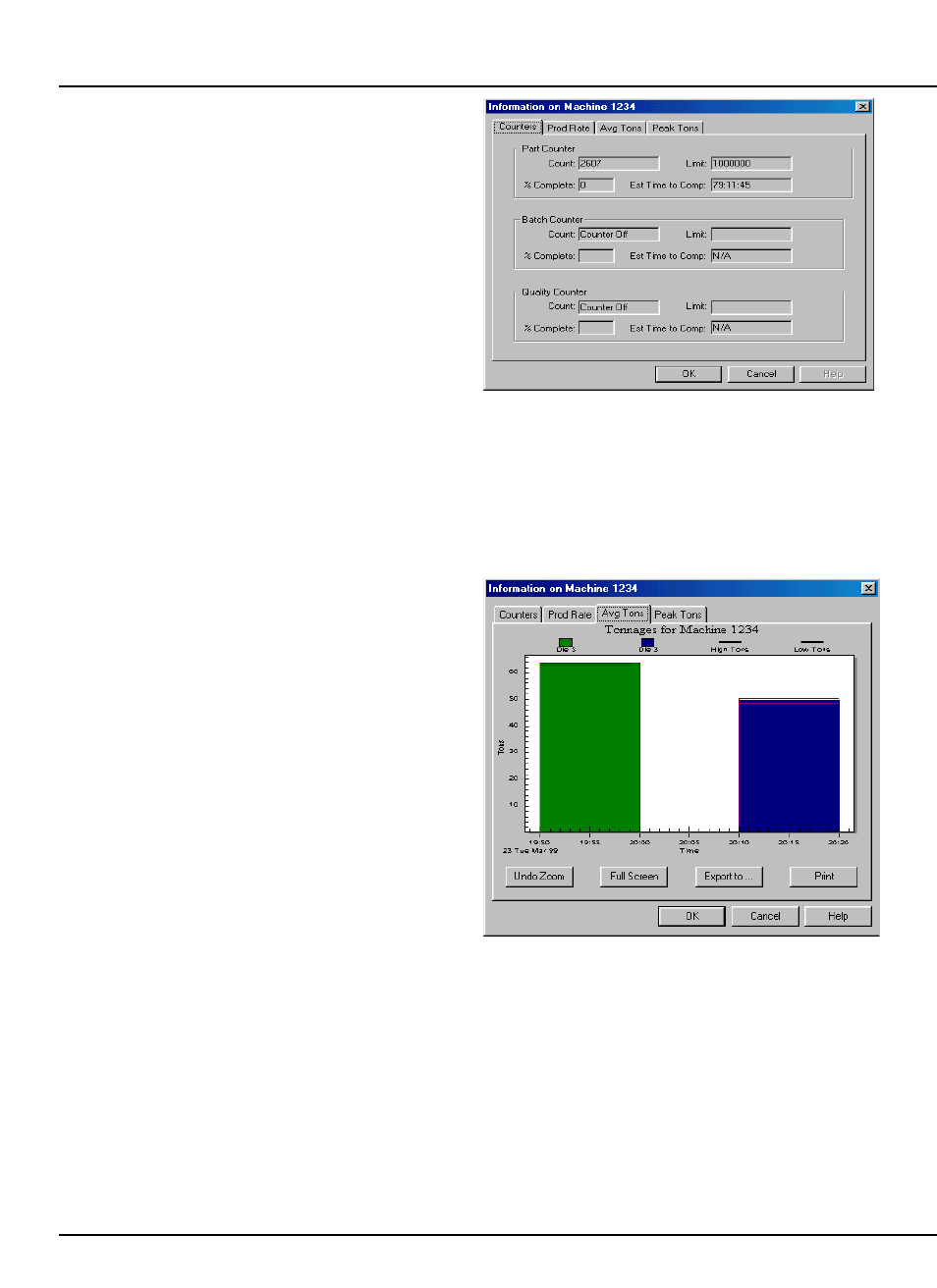

The counter detail screen (“Counters” tab - see

Figure 4.2) is the default for the tabbed dialog box.

This has the status, count, limit, and estimated time

to completion of the part, batch, and quality

counters. Estimated time to completion is given in

hours, minutes, and seconds and is calculated the

same way as the TTC field in the overview screen

(see section 4.1).

Figure 4.2:

Example of Counters Detail View

4.2.2

Average Tonnage Detail

The average tonnage detail screen (“Avg Tons”

tab - see Figure 4.3) graphically shows the average

tonnage for a machine for the current day.

Figure 4.3:

Example Average Tons Detail View

The current day starts with the first shift on that

day and ends with the last shift on that day. This

means that a “current day” may not necessarily start

or end on the same day. For instance, if on Monday

shift 1 is configured to start at 6:00AM Monday and

run to 2:00PM Monday, shift 2 is configured to start

at 2:00PM Monday and run to 10:00PM Monday,

and shift 3 is configured to start at 10:00PM

Monday and end at 6:00AM Tuesday, then

“Monday” runs from 6:00AM Monday to 6:00AM