Linknet – LINK Systems LinkNet I User Manual

Page 14

LinkNet

3.2

manual rev 2.1 March 25, 1999

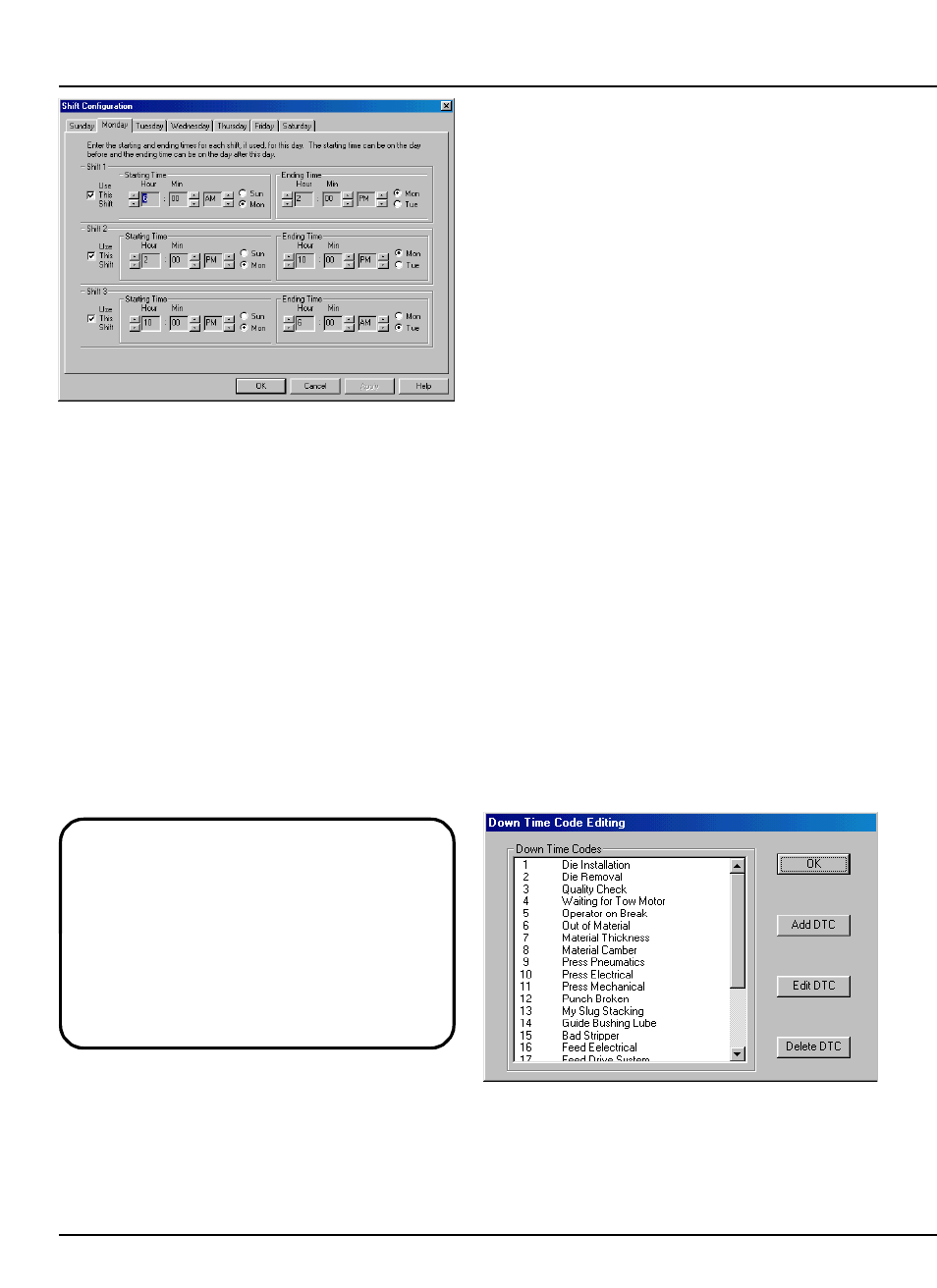

Figure 3.3:

Shift Configuration Dialog

Each day may have up to three shifts

configured. The “Use This Shift” checkbox by each

shift determines whether or not the shift will be used

for that day. Note that a shift can be used some

days and not others - each day is individually

configurable. Also note that each starting time can

be on the day before the current day, and that each

ending time can be on the day following the current

day. This allows the flexibility to assign a shift to a

day on which it does not necessarily start or end.

For example, it may be desired to have a shift that

starts at 10PM on Monday and runs until 6AM on

Tuesday to be considered a Tuesday shift. Likewise,

a shift that starts a 6PM on Monday and runs until

2AM on Tuesday can be considered a Monday shift.

NOTE: Each day except Monday has a “Set

Same as Monday” button. Since the typical

case is for Monday through Friday to have the

same shift times, set the shift times for Monday

first, and then go to each day that should be the

same as Monday and hit the “Set Same as

Monday” button to copy the shift times over to

that day. Any other days can be set according

to need.

The starting and ending time of each shift can be

configured in 10 minute intervals. Use the up and

down arrows next to the hour, minute, and AM/PM

boxes to change each setting. When the shifts are

configured as desired, click on the “OK” button.

No two shifts may overlap in time either on the

same day or across days. If any shifts overlap in

time, a message will be displayed indicating which

days have a problem.

3.3

Configuring Down Time Codes

Down time codes (DTCs) are numeric values

that have a user assigned meaning attached to them.

These codes allow the user to track the uptime,

downtime, and usage of each press. Each DTC has

a user entered description that is downloaded to the

Link equipment on the presses. When a machine has

to be stopped (or is stopped by monitoring

equipment such as tonnage monitors, die protection,

and so on) the operator can enter the reason for the

stop by selecting one of the DTC descriptions that

were downloaded to the press.

The time spent in a DTC is logged by LinkNet

into a database that can be viewed and analyzed.

Problem spots (such as repeated problems with a

feed, material, lubrication, etc.) can be easily

identified by the percentage of down time that they

cause. This enables supervisors to target limited

time, money, and other resources at the areas that

will do the most good in terms of production.

To configure down time codes, select

“Configure” and then “Down Time Codes” as shown

in Figure 3.1. A dialog box similar to Figure 3.4

should appear.

Figure 3.4:

DTC Configuration List

This dialog allows DTCs to be added, edited, or

deleted.

After all additions and changes have been made,

click the “OK” button. The DTC descriptions will