Linknet – LINK Systems LinkNet I User Manual

Page 13

LinkNet

3.1

manual rev 2.1 March 25, 1999

3. Configuration

After the software is installed, it must be

configured. This consists of the following steps:

@

Select a communications port for LinkNet to use

to “talk” to the presses.

@

Set the number, days, and starting times of

shifts.

@

Enter down time codes and their descriptions.

@

Tell LinkNet what machines are present.

@

Tell LinkNet what dies are present.

@

Configure Preventive maintenance.

3.1

Configuring the Comm Port

LinkNet uses a standard RS-232 serial port

(commonly called a “comm port”) to communicate

with the machines on the factory floor via an

external RS-232 to RS-485 converter. No boards

have to be installed or configured on the host

computer. There are typically two comm ports

installed in most computers, “COM1" and “COM2".

A spare comm port must be available for LinkNet to

use.

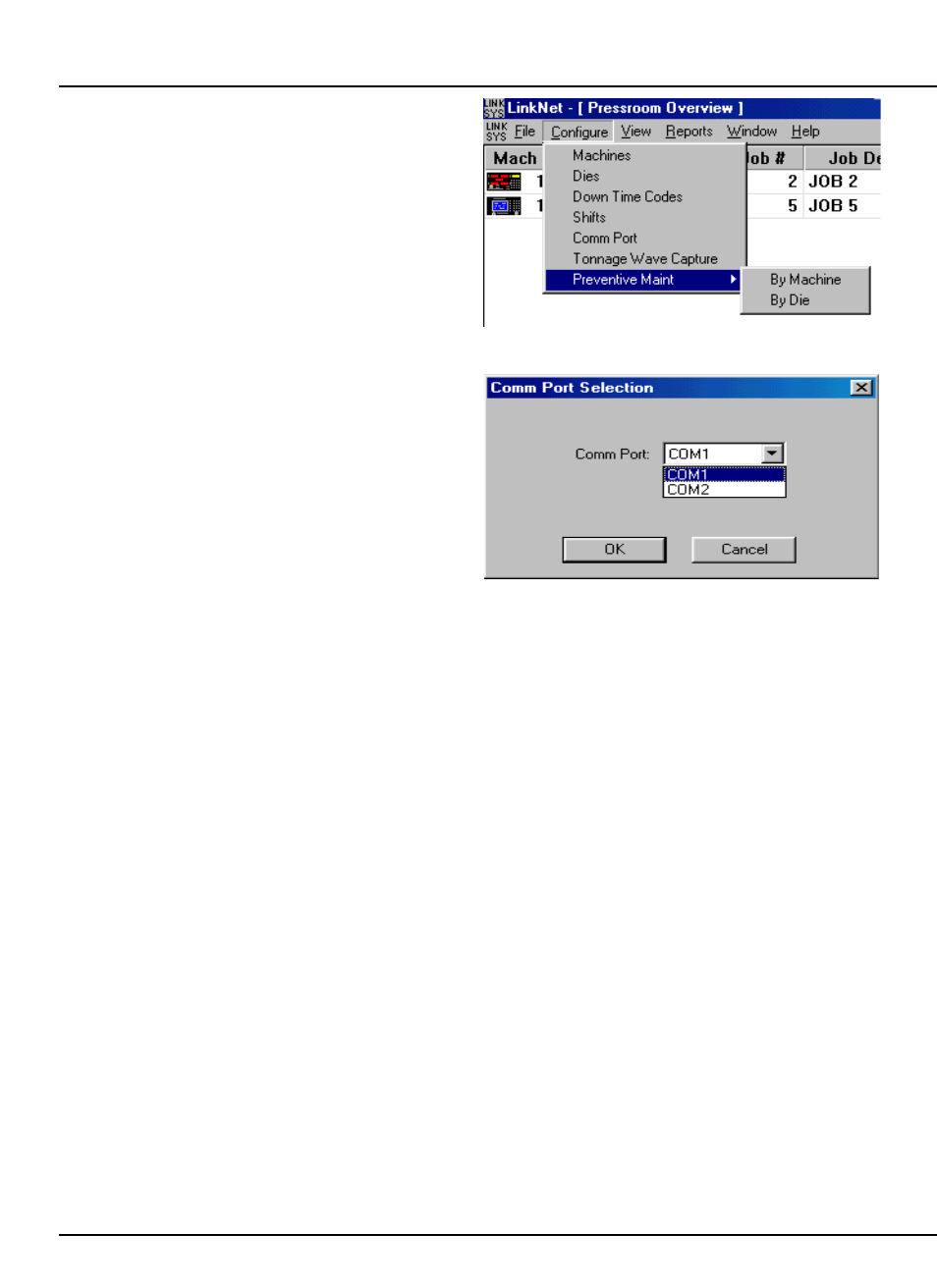

Select “Configure” and then “Comm Port” from

the menu in LinkNet as shown in Figure 3.1 and a

dialog box similar to Figure 3.2 should appear. Note

that only comm ports that are not currently in use

(by anything other than LinkNet itself) show up in

the list. Pick the comm port that will be used by

LinkNet from the list and click on the “OK” button.

Figure 3.1: Configuration Menu

Figure 3.2: Comm Port Selection Dialog

3.2

Configuring Shifts

LinkNet collects information only while in a

shift. This keeps the system from needlessly filling

up the hard drive with information not related to

production and lets many types of information be

tracked by shift. The relative performance of

different shifts can then be compared and analyzed.

To configure shifts, select “Configure” and then

“Shifts” from the LinkNet menu as shown in Figure

3.1. A dialog similar to Figure 3.3 should appear.