HITEC Eclipse 7 User Manual

Page 22

Aircraft(ACRO) Section

22

REV - Servo Reversing

The servo reverse function may be used when you need

to change the direction that a servo responds to a control

stick motion. When you use this function,

BE SURE THAT

YOUR CONTROL IS MOVING THE CORRECT DIRECTION.

If you are using any preprogrammed mixers such as

flaperon, be sure to set correct travels in the REV menu

setting up the preprogrammed function.

Reversing Servos

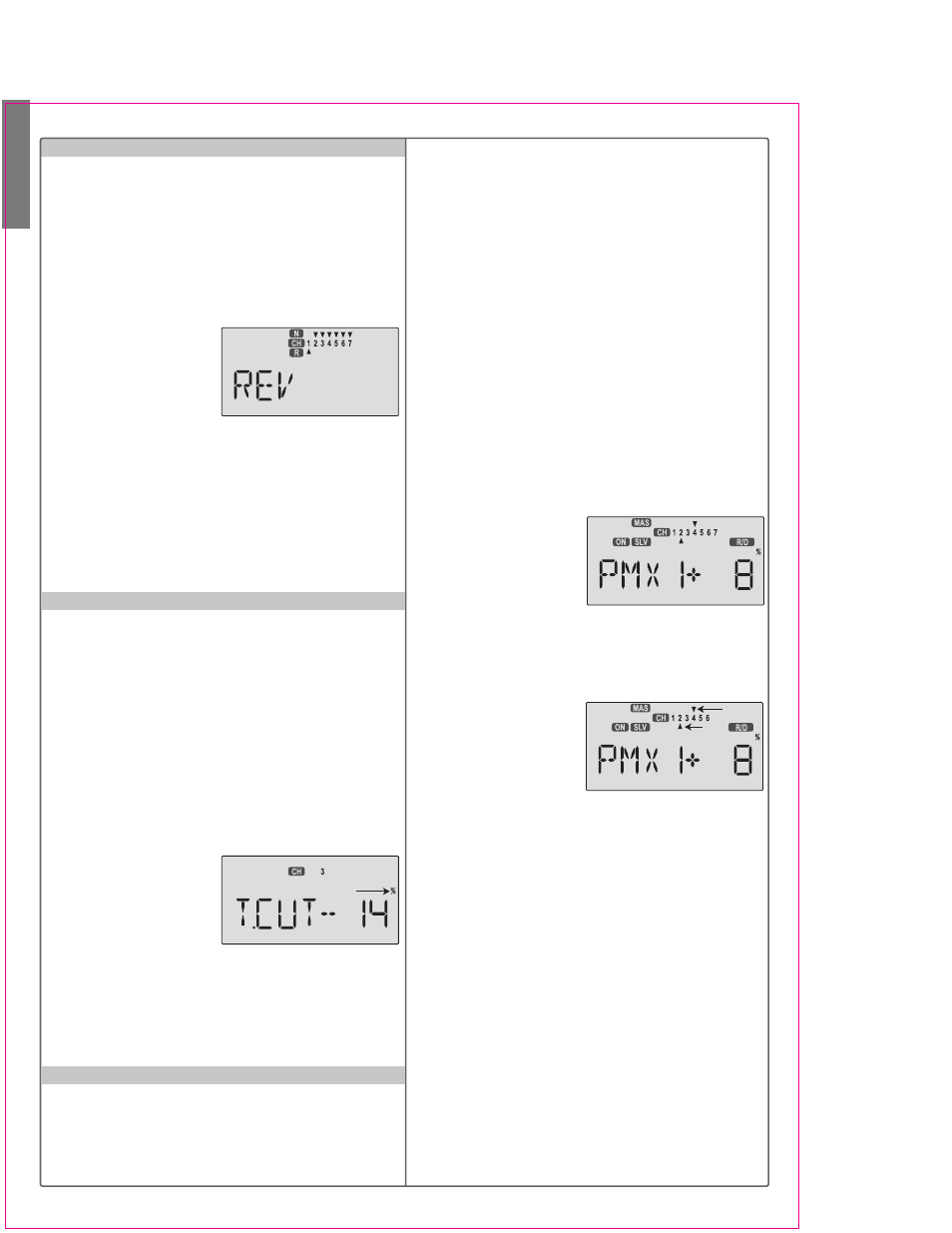

1. Get to the REV screen with the Edit Up Down keys.

2. Use the Data +Increase

or -Decrease key to select

the channel you wish to

reverse. The active channel

number will flash.

3. Toggle between normal (N) and reverse (R) with the

Active/Inhibit (Clear) key. The arrow above the number

indicates normal travel, while the arrow below indicates

reversed travel (the figure shows all channels normal,

none reversed).

4. Repeat this procedure for each channel needing to

be reversed.

5. Return to the regular operating mode by pressing the

two Edit Up Down keys simultaneously.

T.CUT - Throttle Cut (Engine Shut off) Function

The Throttle Cut function provides you an easy way to

stop the engine by simply pressing a button with the

throttle stick at idle, which commands the throttle servo to

move a prescribed amount. The throttle servo moves to

the selected cut position when the Cut button is pressed

and the throttle stick is below 50%. Above 50% throttle,

the cut button has no effect. The activation direction may

be chosen by the owner.

Setting up the Throttle Cut function

1. Get to the T.CUT screen with the Edit Up Down keys.

2. Place the throttle at its idle position (towards bottom

of transmitter). Use the Data -Decrease key to select the

amount of motion of the throttle servo you wish - normally

you want to completely

close the carburetor, but be

careful not to choose too

much travel which will stall

the servo. You may see the

servo move when you press the Active/Inhibit (Clear)

button. A maximum of 72% may be chosen, but only use

the amount you need to fully close the carburetor without

stalling the servo.

3. Return to the regular operating mode by pressing the

two Edit Up Down keys simultaneously.

Flashing

Your

Eclipse 7 system contains FIVE separate program-

mable mixers (PMX1 - PMX5) with unique capabilities.

You may use mixing to correct unwanted tendencies of

the aircraft during aerobatics. Each one of these mixers

may be programmed to do things that are not built-in

PMX1 to PMX5 - Programmable Mixes 1, 2, 3, 4, & 5

Master

Slave

programs. This makes them useful for all sorts of

different things. Note that the mixers must be turned on

by flipping a switch - if you need them to be on all the

time, you must not touch that switch. The elevator

dual-rate switch in its down position turns on mixers (if

they've been activated). The method to be used to prog-

ram mixers is given for Mixer #1, but the other mixers

may be programmed in an identical fashion. You can use

both PMXs to create a custom dual elevator function,

where you use two servos for your elevator control, one

for each side, the second plugged into an unused

receiver channel and mixed from elevator (if you do this,

you must be careful to keep the mixer on at all times).

Or you may also use the mixers for correcting unwanted

flying tendencies, like automatically applying a bit of

rudder with throttle to account for torque/P-factor effects,

to a corrective elevator motion during knife-edge flight to

correct for an undesired tucking tendency (the latter is

described in the ACRO model setup section and below).

1. Call up the mixer screen

by repeatedly pressing one

of the Edit Up Down keys

until a PMX window

appears. The default is for

the function to be inhibited. To activate, press the

Active/Inhibit (Clear) key. This will cause the INH dis-

play to change to a display showing 100%, Master and

Slave indicators, and a flashing ON or OFF depending on

the position of the mixer's on-off switch.

2. Now you'll select the

Master channel for the

mixing, the channel that

causes the mixing to occur.

Press the Cursor Right key

to get the master channel indicator MAS flashing on and

off, then press the Data +Increase or -Decrease keys to

move the top arrow over the number of the desired

master channel, 1 - 7.

3. Next you'll put in the Slave channel, the one that is

affected by motion of the master channel. Press the

Cursor Right key to get slave channel indicator SLV

flashing on and off, then press the Data +Increase or

-Decrease keys to move the bottom arrow underneath

the number of the desired slave channel.

4. Now we'll input the mixing percentage, which tells how

much the slave channel responds to the master channel.

Press the Cursor Right key to cause the percent(%) sign

to the right of the large number to flash on and off.

Note that you can set the percentage for the mixer on

each side of the master channel's control's motion by

moving the master channel's control back and forth.

The motion of the master channel's control is also

indicated by the R/D (= Right/Down) or L/U (= Left/Up)

indicator in the window.

5. Hold the master channel's control to one side, and then

Using the Programmable mixers