General wiring information, Wire gauge and clamp screw torque – Delta RMC151 User Manual

Page 29

Appendix A: Wiring

General Wiring Information

For CE compliance and to minimize electrical interference:

• Use twisted pairs for all wiring where possible.

• Use shielded cables for all wiring.

• Keep RMC wiring separate from AC mains or conductors carrying

high currents, especially high frequency switching power such as

conductors between servo drives and motors or amplifiers and

proportional valves.

For UL and CUL compliance:

• Power supply must be Class 2.

• All RMC inputs and outputs must be connected to Class 2 circuits

only.

For products labeled Class I, Division 2:

• Conductors must be copper only. Follow wire gauge and clamp

screw torque as listed below.

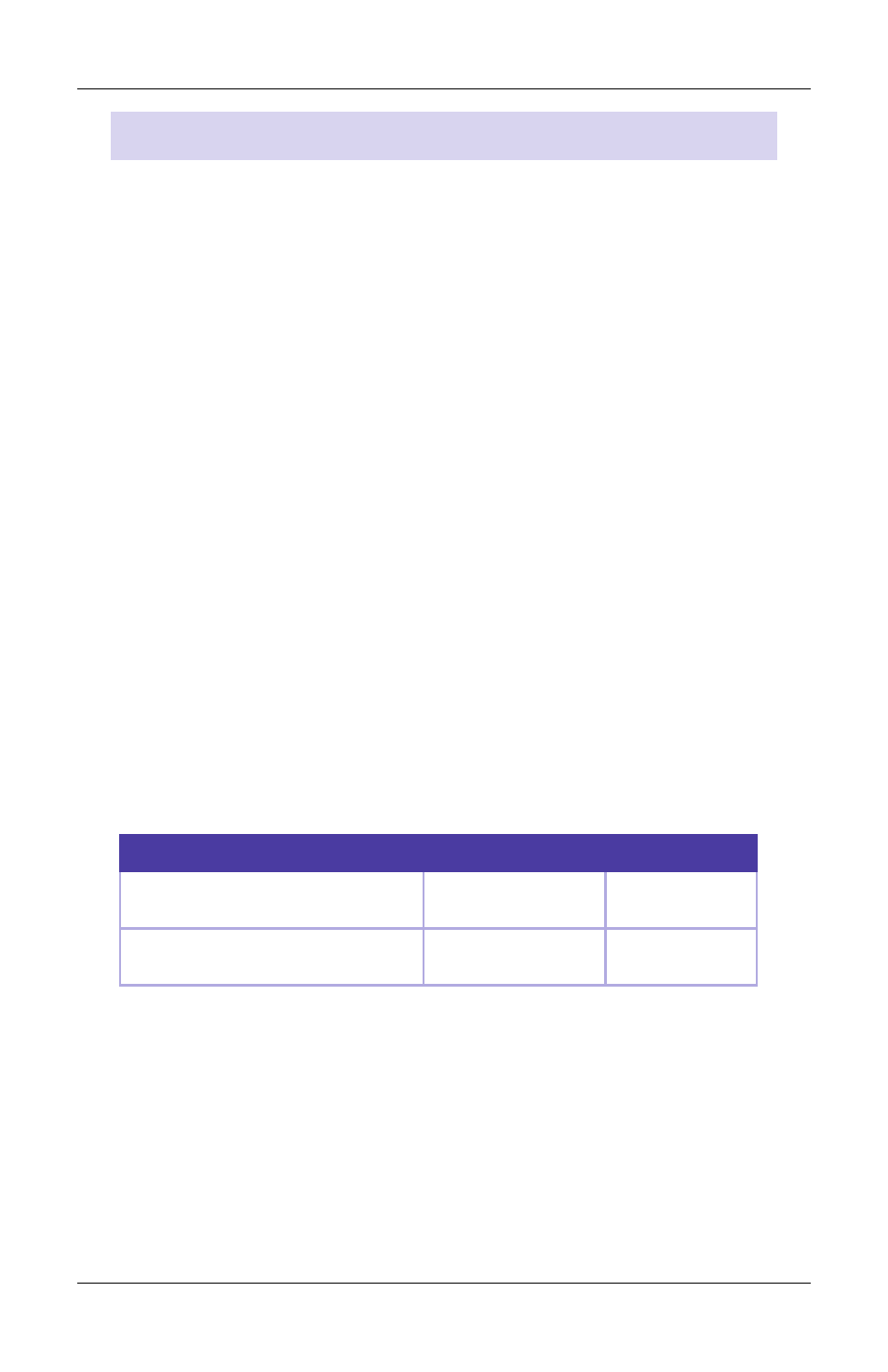

Wire Gauge and Clamp Screw Torque

Use the table below to determine proper wire gauge and torque for

the clamp screws on the terminal blocks.

Module

Gauge

Torque

RMC150E, MDT (M), SSI (S),

Analog (H, A, G), RES (R)

26-12 AWG

( 0.13 - 3.3 mm

2

)

4.5 lb-in

(0.51 Nm)

DI/O, UI/O

28-16 AWG

( 0.08 - 1.3 mm

2

)

2.2 lb-in

(0.25 Nm)

deltamotion.com

27