Seat adjustment, Belt replacement, Mechanical transmission drive belts – Ariens 929000 User Manual

Page 66: Intermediate shaft drive belt, Trantmistion drive belt — figure 35, Hydrostatic transmission drive belt

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Bare equal and so distance C is between 1/8" to 1/16"

less than distance D.

NOTE;

Use

following

procedure

to

shorten

or

lengthen tie rods;

1. Loosen jam nuts on both ends of tie rods,

Figure 34.

2. Rotate tie rods until distances A and B, Figure

34, are equal and distance C is 1/8" to 1/16" less than

D.

3. Tighten jam nuts securely.

SEAT ADJUSTMENT

The seat is adjustable front or back to any orie of

six

different

positions.

Adjustment

is

made

by

removing the four mounting bolts located under the

Seat,

moving

the

seat

to

the

most

comfortable

position and then replacing the mounting bolts in the

appropriate holes.

■

BELT REPLACEMENT

If it becomes necessary to replace one of the

tractor drive belts, the following diagrams show the

proper placement of the belts and belt guides. After

installing

a

belt it will be necessary to follow the

adjustment procedures outlined in the ADJUSTMENT

section of this manual.

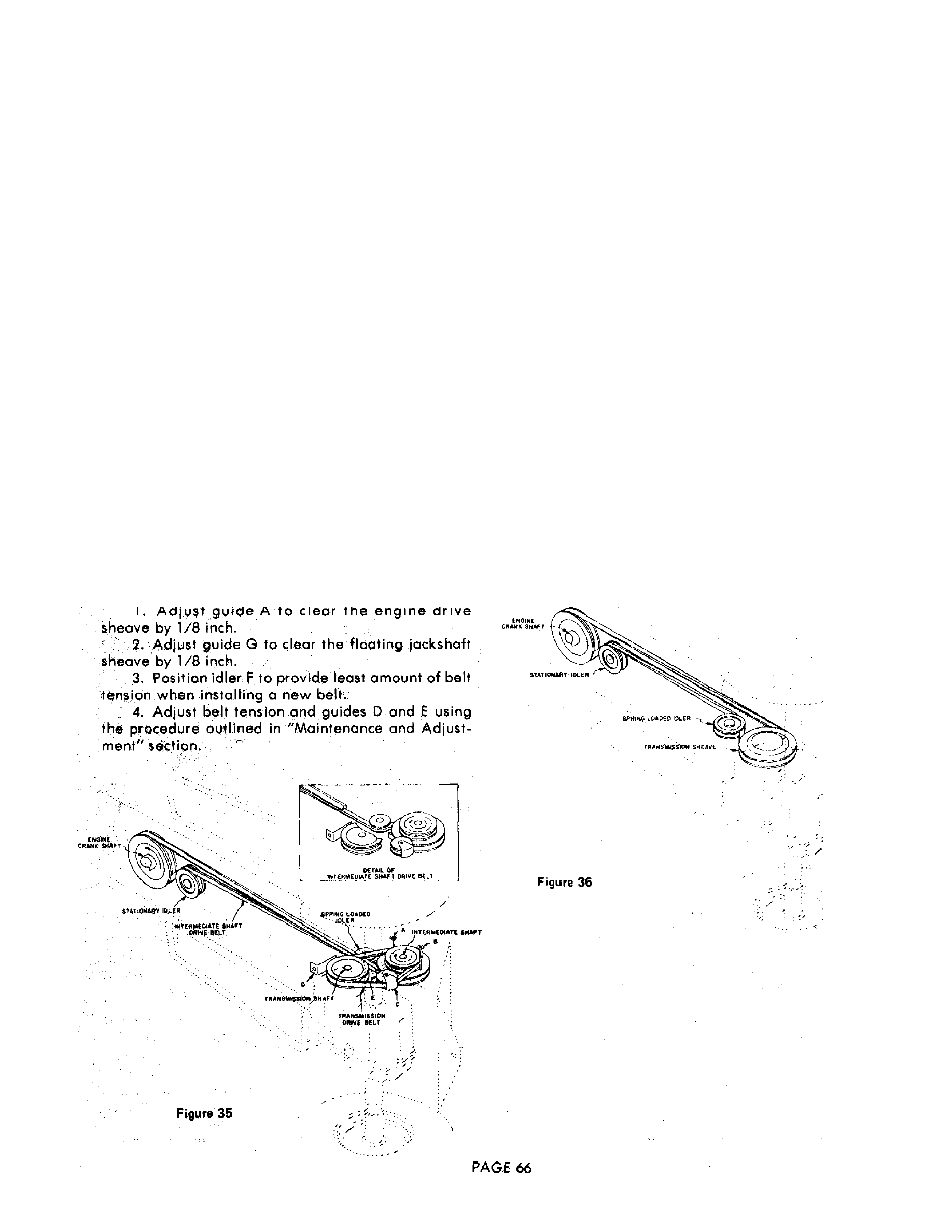

MECHANICAL TRANSMISSION DRIVE BELTS —

Figure 35

Intermediate Shaft Drive Belt

Follow the instructions outlined in the ADJUST

MENT section.

Trantmistion Drive Belt — Figure 35

1.

Position guides A and B 1/8" from drive

sheave at the points where belt is tangent to the

sheave.

2.

Position guide D, 1/8" from the transmission

sheave.

3. idler E is mounted in

a

slotted hole. Position to

provide lease amount of belt tension when installing

a

new belt.

4. Place guide C 1/8" from the belt in such a

position that it does not bind the belt in any position of

the idler. ..

5.

Adjust

belt

tension

using

the

procedure

outlined in ADJUSTMENT section.

HYDROSTATIC TRANSMISSION DRIVE BELT —

Figure 36

No

adjustments

are

necessary

when

replacing

the hydrostatic transmission drive belt Belt tension is

maintained by the spring-loaded idler.

PTO DRIVE BELT — Figure 32