Hydrostatic control lever brake adjustment, Front wheel toe-in adjustment – Ariens 929000 User Manual

Page 65

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

í

HYDROSTATIC TRANSMISSION DRIVE BELT

(HYDROSTATIC MODEL ONLY)

The

hydrostatic

drive

belt

does

not

require

tightening. Belt tension is achieved by a spring-loaded

idler. Replace the belt if it has stretched or worn to the

point where it begins to slip.

HYDROSTATIC NEUTRALIZER PEDAL ADJUSTMENT

(HYDROSTATIC MODEL ONLY)

The linkage should be adjusted to automatically

return the hydrostatic control lever to the "park-start"

(neutral) position when the neutralizer pedal is de

pressed.

To adjust the neutralizer pedal, place control

lever in the "park-start" position, loosen bolt A,

Figure 33, depress the foot pedal and apply the brake

lock, then retighten bolt A.

FRICTION BRAKE'-

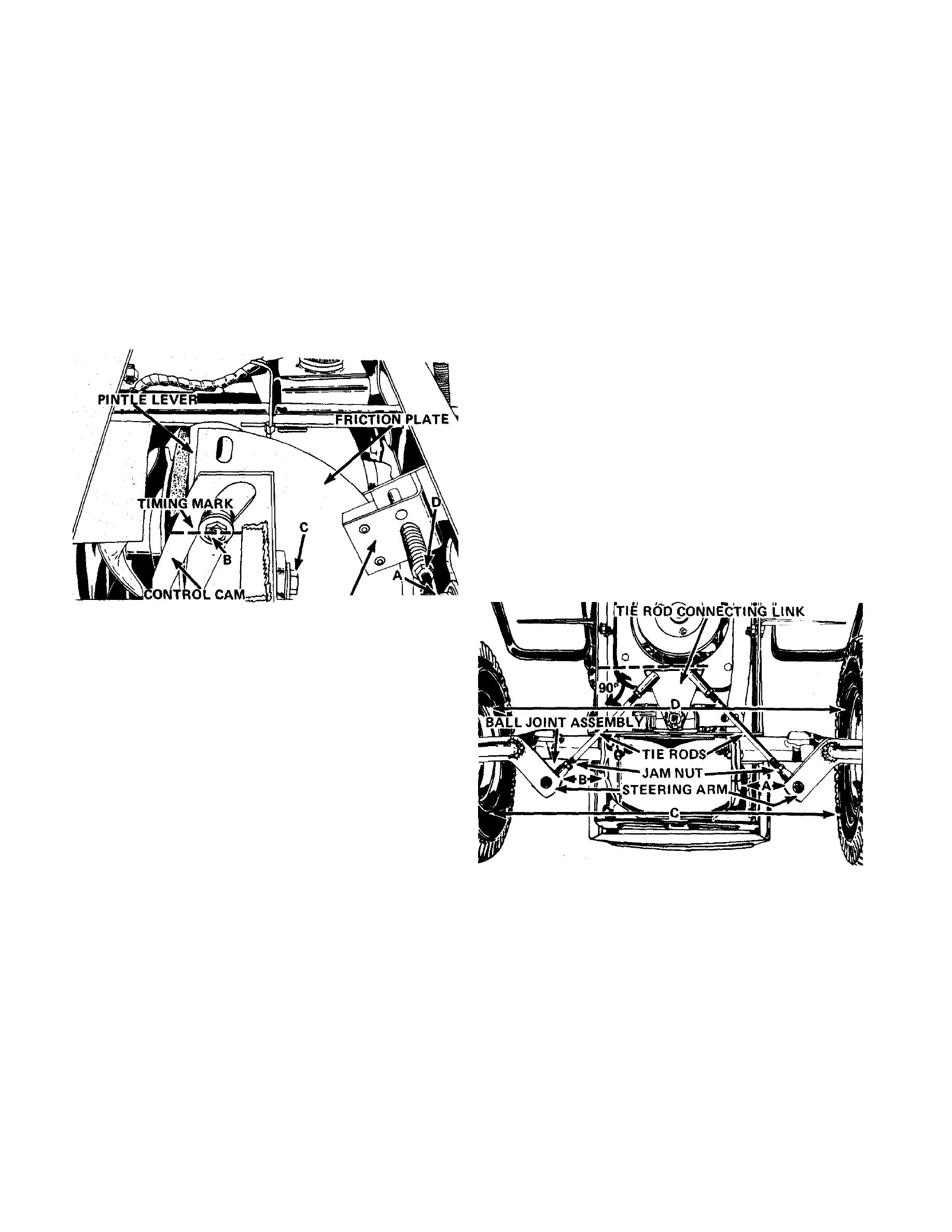

Figure 33

Release brake lock, move the control lever to a

forward position then depress the foot pedal. The

control lever should return to "park-start" (neutral).

Repeat process by placing control lever in reverse.

When the adjustment is properly made, the control

lever will automatically return to neutral from either

forward or reverse when the neutralizer pedal is

depressed.

IMPORTANT:

NEVER

DEPRESS

BRAKE

PEDAL

AND

MOVE

THE.

HYDROSTATIC

CONTROL

SIMUL

TANEOUSLY.

THE

LINKAGE

IS

INTERCONNECTED

AND

DAMAGE

OR

MIS-ADJUSTED

LINKAGE

COULD

RESULT.

on the cam. If the timing mark does not align with the

bolt head, loosen bolt C and move the cam up or down

as required to align the bolt head with the timing

mark.

Tighten

nut

C

securely

after

making

the

adjustment.

3. Jack up rear of the tractor until rear tires are

clear of the ground.

4.

Start engine and increase speed to full

throttle.

5.

Loosen bolt B slightly. Insert a screwdriver

through the slots in the friction plate and the pintle

lever. Figure 33. Pivot the pintle lever left or right

until the rear tires stop rotating and retighten bolt B.

A

WARNING:

KEEP

HANDS

AND

ANY

LOOSE

CLOTHING

AWAY

FROM

THE

HYDROSTATIC

COOLING

FAN

AND

DRIVE

BELT

WHEN

MAKING

ADJUSTMENT.

THESE

PARTS

MUST

ROTATE

WHEN

MAKING

THE

NEUTRAL

ADJUSTMENT.

HYDROSTATIC CONTROL LEVER BRAKE ADJUSTMENT

The hydrostatic control lever friction brake must

be adjusted so the control lever moves through the

"forward" and "reverse" modes with a minimum of

force. However, due to the neutral tendency of a

hydrostatic transmission to neutralize, the brake must

be tightened sufficiently so the tractor maintains any

selected speed setting.

To adjust the friction brake, tighten or loosen bolt

D, Figure 33, until the proper braking is reached.

Figure 34

I

HYDROSTATIC NEUTRAL ADJUSTMENT

(HYDROSTATIC MODEL ONLY)

The hydrostatic controls should be adjusted so the

rear tires stop rotating when the control lever is

returned to neutral either manually or with the

neutralizer pedal.

Use the following procedure to adjust neutral:

1.

Check

HYDROSTATIC

NEUTRALIZER

PEDAL

ADJUSTMENT.

If

required,

adjust

as

previously

explained.

2. Check position of the timing mark on control

cam. With the shift lever in the "park-start" position

and brake lock engaged, the center line of bolt head

B, Figure 33, should be aligned with the timing mark

FRONT WHEEL TOE-IN ADJUSTMENT

Proper toe-in of the front wheels is necessary to

assure proper steering and to reduce tire wear.

Correct toe-in is when the front of the wheels are 1/8"

to 1/16" closer together than the rear of the wheels

(measured at the horizontal center line of the rim

flanges).

If the steering develops a wandering character

istic or if excessive tire wear develops, the toe-in of

the front wheels should be checked. If the toe-in is not

correct, adjust as follows:

1. Turn steering wheel until the rear edge of the

tie rod connecting link is perpendicular (90 degrees)

to the tractor frame as shown in Figure 34.

2. Adjust length of tie rods until distances A and

PAGE 65