Transmission cooling system, Bleeding the transmission – Ariens 929000 User Manual

Page 60

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

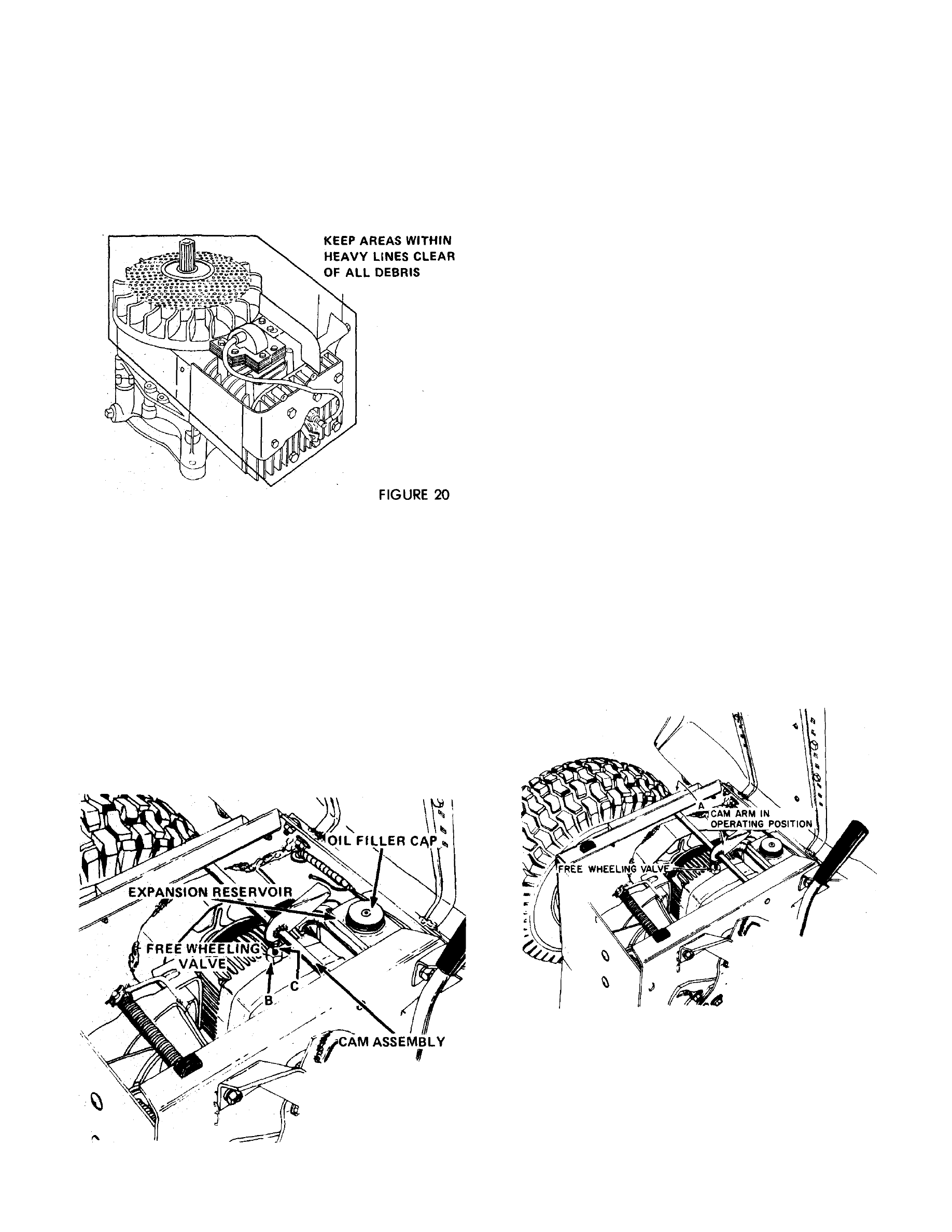

It is essential that the rotating screen, engine

cooling fins and the exhaust system be kept free of

dirt and debris which could cause the engine to

overheat.

To avoid overheating and possible engine dam

age, periodically remove the shrouding from

around

the cooling fins. Figure 20, and clean the area shown

within the heavy black line of all grass, dirt or chaff

accumulation.

TRANSMISSION COOLING SYSTEM

Dirt and grime occumulations on transmission

cooling fins can cause overheating. Check and clean

the cooling fins every 50 hours of operation or

quarterly. In extremely dusty or dirty conditions,

clean the cooling fins more frequently.

C A U T IO N :

R E S E R V O IR .

K E E P

WATER

A W A Y A N D O F F

Check the hydrostatic cooling fan blades periodi

cally to assure that the blades are not bent or broken

and that the fan is in good condition.

FiGURE 21

BLEEDING THE TRANSMISSION

If for any reason the oil level is ever permitted to

fall below the expansion reservoir, air may enter the

system causing the transmission to malfunction. If this

should occur, use the following procedure to "bleed"

(remove air from the transmission);

1. Thoroughly clean all dust, dirt and grime from

the free-wheeling valve, the oil filler cap and sur

rounding areas. Figure 21.

2. Remove nut A, Figure 22 from the left end of

the com assembly shaft and slide the cam assembly to

the right until the cam arm is free of the valve

actuating rod.

3. Loosen nut B first and then valve actuating rod

C, Figure 21, and remove the rod. Be extremely

careful not to allow dirt to enter the transmission.

4. Remove the expansion reservoir filler cap and

add 'Type A" transmission fluid until the reservoir is

Vi full.

5. Jack up rear of the tractor, start the engine

and operate at a slow idle speed.

6. With engine running, move speed control

lever to both forward and reverse positions until oil

appears at the free-wheeling valve hole.

7. Replace free-wheeling valve actuating rod C

and tighten nut B, Figure 2l, to 30 inch-pounds.

Tighten both parts carefully to prevent the small

rubber o-rings inside the cap from becoming dam

aged.

8. Replace cam assembly. Figure 22. Tighten nuts

A so the cam arm intersects the center of the valve

actuating rod and the shaft has 1/32" end play.

9. Recheck the oil level. If necessary add oil until

the reservoir is half full.

FIGURE 22

N O T E : T H E C A M A R M M U S T B E IN T H E F O R W A R D

P O S IT IO N

BEFORE THE

T R A C T O R C A N B E O P E R A T E D .

PAGE 60