Steering gears, Intermediate steering shaft, Grease fittings – Ariens 929000 User Manual

Page 59: Points to oil, General, Air cleaner service, Engine cooling system, Maintenance

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

STEERING

gears

Apply a light coat of Ariens Moly Lithium grease

to the steering gears every 50 hours of operation. See

Figure 12.

INTERMEDIATE STEERING SHAFT

Apply oil to the bearing surfaces of the blocks

every 50 hours of operation. See figure 16.

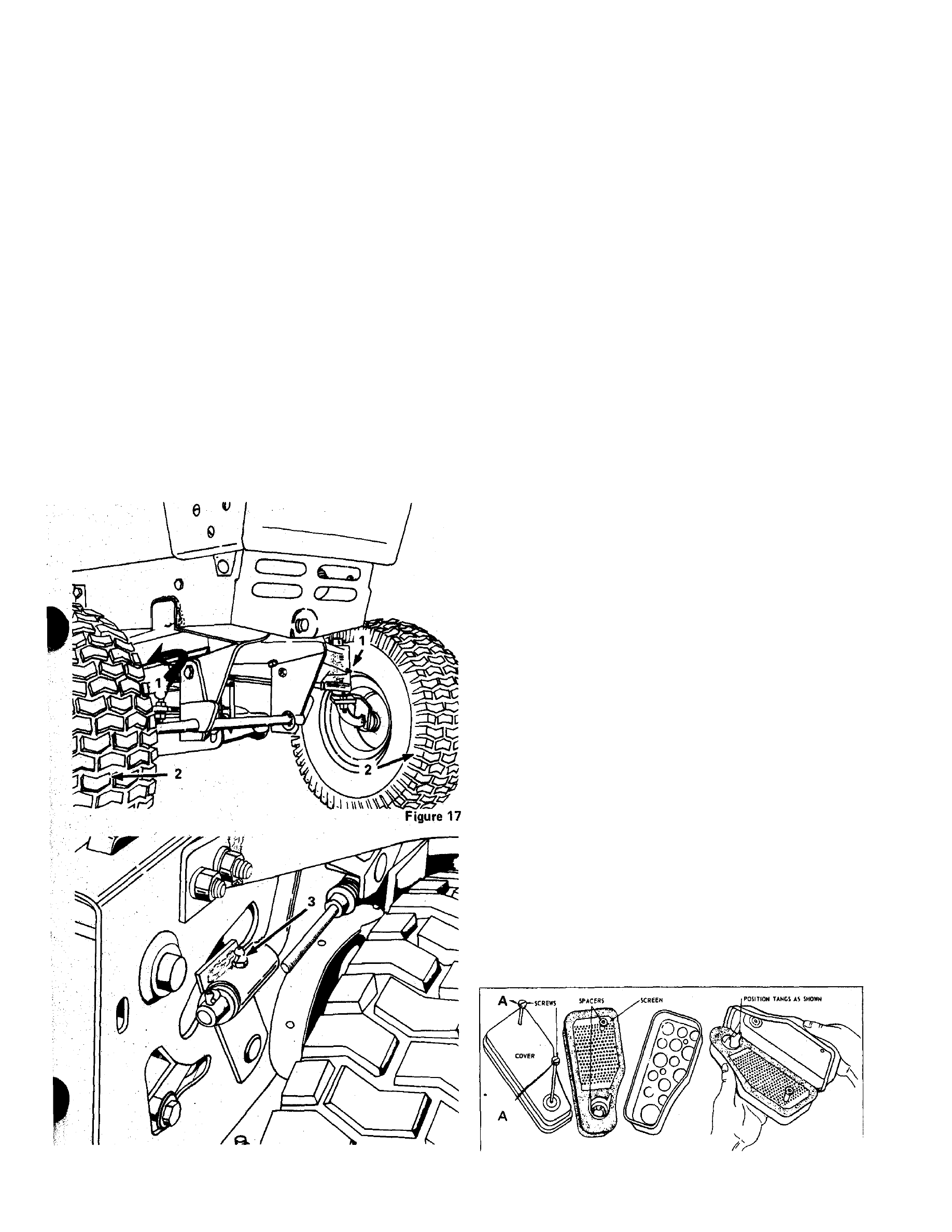

GREASE FITTINGS

Following is a list of the grease fittings with

reference numbers that identify each location on the

corresponding pictures. Figures 17 & 18. Each fitting

should be wiped clean before and after lubrication.

Grease each fitting every 50 hours of operation with

Ariens Moly Lithium gr«ase.

1. Figure 17 — Right and left king pin.

2. Figure 17 — Right and left front wheel.

3. Figure 18 — Hydrostatic control arm pivot

(hydrostatic models).

POINTS TO OIL

Periodically oil the lift point pivots, front axle

pivot, control linkage pivots and the floating inter

mediate shaft pivots to insure long life and smooth

operation of the parts.

There is no lubrication required on the mower.

IM P O R T A N T :

K E E P G R E A S E A N D O IL O F F T H E

B E L T S T O P R E V E N T B E L T S L IP P A G E A N D D E T E R IO R A

T IO N .

MAINTENANCE

GENERAL

Ariens dealers will provide any service which

may be required to keep the Lawn Tractor operating

at peak efficiency. Ariens Company recommends that

you contact an Ariens dealer before making any

adjustments to this tractor. Refer to the engine in

struction manual and engine nameplate for engine

maintenance instructions. If repairs or service are

required for the engine, see your Ariens dealer or the

nearest authorized engine service station.

AIR CLEANER SERVICE

Clean the air cleaner and re-oil the element every

25 hours under normal operating conditions. When

operating in extremely dusty conditions, perform this

service at more frequent intervals. Use the following

procedure to service the air cleaner:

1. Raise the tractor hood. Remove screws A,

Figure 19, and lift off complete air cleaner assembly.

2. Remove screen and spacers from the foam

element. Figure 19.

3. Wash foam element in kerosene or liquid

detergent and water to remove dirt. Wrap foam in

cloth and squeeze dry. Let dry overnight.

4. Saturate foam element in clean engine.

Squeeze to remove the oil.

5. Re-assemble parts and re-install complete

assembly on the carburetor.

N O T E :

W h e n r e -a s s e m b lin g th e p a rt s, m a k e

c e rta in th e fo a m e le m e n t e x te n d s o v e r th e e d g e o f

th e a ir c le a n e r b o d y . T h e fo a m e le m e n t w ill f o r m a

p r o te ct iv e s e a l.

IM P O R T A N T :

N E V E R R U N T H E E N G IN E W IT H

T H E A IR C L E A N E R R E M O V E D !

ENGINE COOLING SYSTEM

The engine is air cooled. Grass particles, chaff

and dirt may clog the cooling system, especially when

mowing dry grass or operating in extremely dusty

conditions. Continued operation with a clogged

cooling system may cause severe overheating and

possible engine damage.

Figure 18

Figure 19

PAGE 59