Important notes concerning the, Operation of the exhaust waste vapor condenser, Notice – VACUUBRAND PC 3012 VARIO plastic housing User Manual

Page 46

page 46 of 129

wise dangerous mixtures. If in doubt, use inert gas.

To reduce condensation in the pump, do not pump vapor

before the pump has reached its operating temperature.

Open the gas ballast valve when pumping condensable

vapors. Turn gas ballast cap to open valve.

For

condensable vapors (water vapor, sol-

vents, etc.):

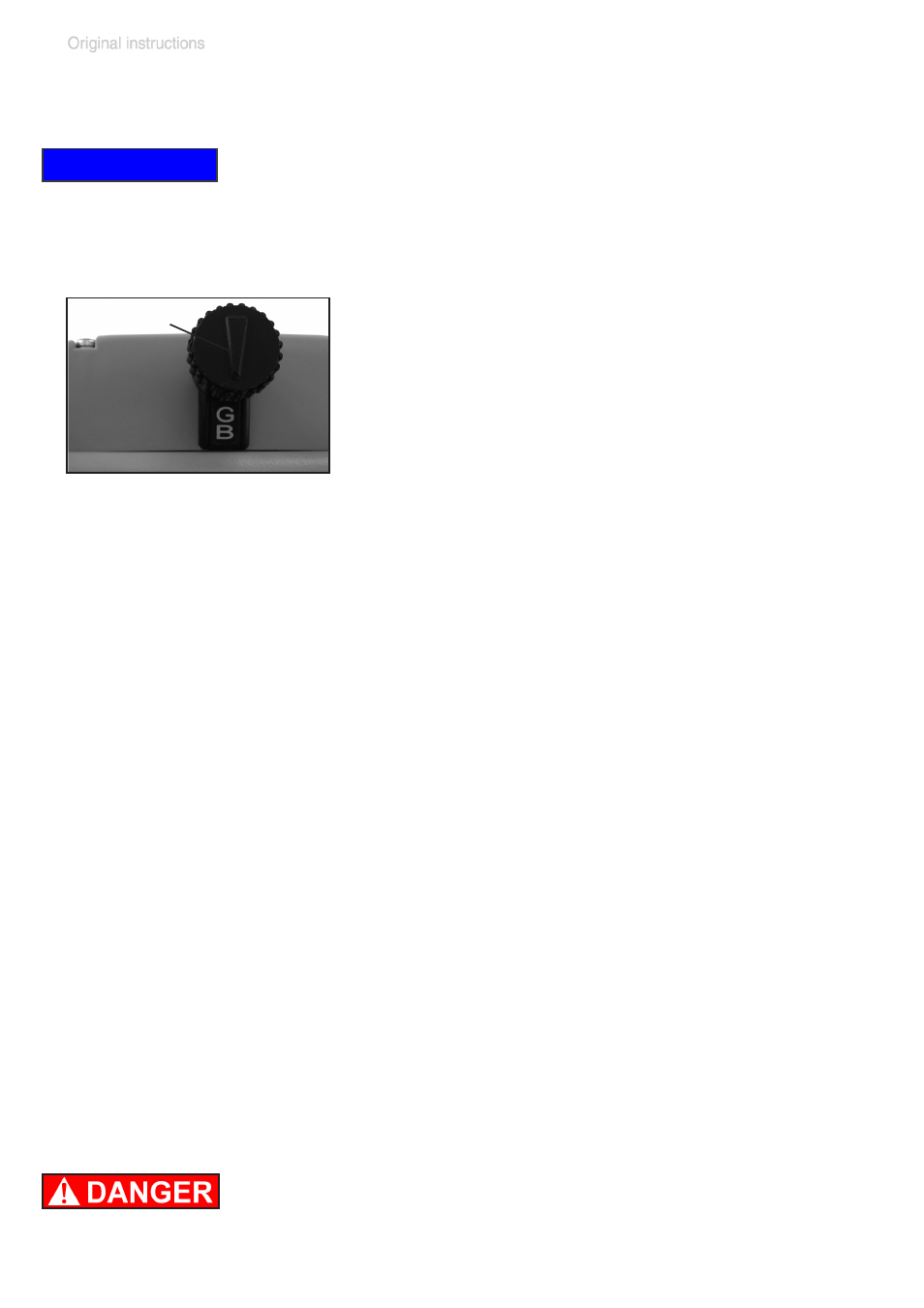

- The gas ballast valve is open if the arrow on

the gas ballast cap is pointing towards the

labelling ”GB”.

MD 12C/MV 10C VARIO-B and PC 301x

VARIO: The gas ballast valve is open if

the arrow on the gas ballast cap is pointing

away from the pump‘s inlet.

- With gas ballast valve open, the ultimate vacuum will

be reduced.

- Use inert gas for gas ballast to avoid the formation of

explosive mixtures. A special adapter fitting is needed

to connect an inert gas supply line (see “Accessories”,

pg. 92). This adapter replaces the standard gas bal-

last cap and allows for an inert gas line to be connect-

ed via a KF DN 16 small flange at a maximum supply

pressure of 17.5 psi (1.2 bar) absolute.

- Close the gas ballast valve by turning the cap 180°.

In case of low boiling solvents (when the formation of

condensate is unlikely), the use of gas ballast might be

unnecessary. Operating the pump without gas ballast in-

creases the solvent recovery rate at the exhaust waste

vapor condenser.

Important notes concerning the operation of

the exhaust waste vapor condenser

➨

Connect the exhaust to a suitable treatment system to

prevent the discharge of dangerous gases and vapors

to the surrounding atmosphere.

NOTICE

gas ballast (9)

(open)