Attention, Figure 3 – Tuffy Security 167 User Manual

Page 3

Page 3 of 4 – 10/13/2010 – Rev6/8/2011

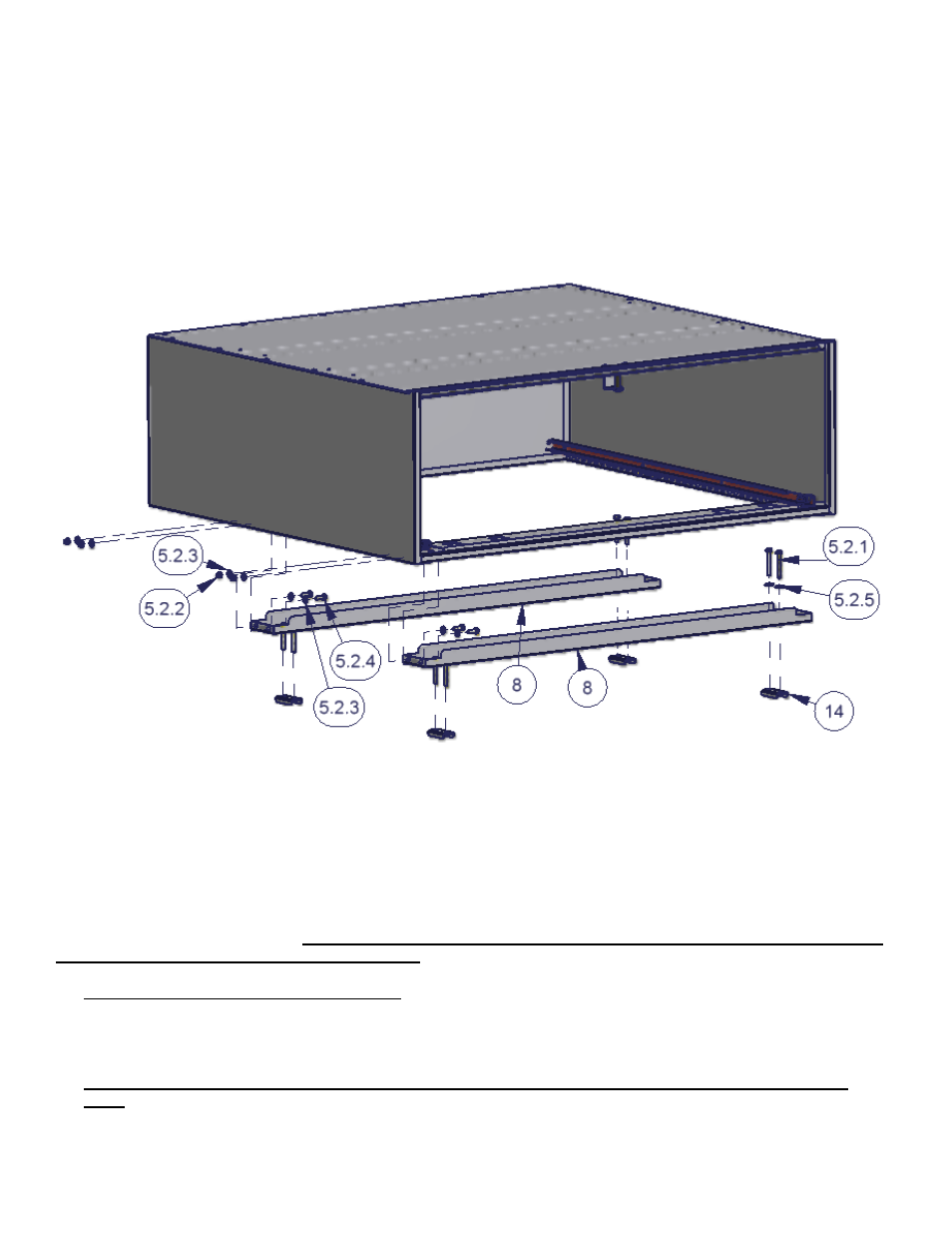

5. With the enclosure placed in the desired mounting location insert the (4) #14 clamps on the underside of the seat

anchors in the vehicle floor and

using a ½” socket, extension, and ratchet fasten them to the #8 mounting brackets

with the #5.2.1 Bolts and #5.2.5 Washers (#5.2.6 Bolts are a shorter length and may alternately be required for

mounting in some vehicles). Be sure the anchor point is completely enclosed between the B

olts and is “sandwiched”

between the #14 clamp and #8 mounting bracket and cannot slip out from behind it. Do not over tighten these bolts

or damage to the #8 mounting brackets will occur due to the necessary gap. (See Figure 3)

6. Insert the drawer and test the operation. Make sure there is clearance between the drawer handle and the rear

tailgate. Test to make sure that access to any important compartments in the floor or side panels are maintained.

FIGURE 3

ATTENTION:

FREQUENT LUBRICATION IS NECESSARY ON THE LOCKING SYSTEM

Th

e pushbutton lock contains an “O” ring seal to protect the interior from dust and water. If this mechanism is not

lubricated regularly it will become difficult to operate and it may not return to its home position preventing the key from

operating the lock. If this happens simply pull up on the pushbutton to manually bring it back to its home position.

Lubricate the pushbutton with a light lubricant such as silicone spray. The pushbutton may have to be periodically

disassembled and cleaned.

Required Periodic maintenance: Failure to perform periodic maintenance can result in the loss of access inside

the security enclosure and failure of components.

Lubrication is required for all moving parts. The schedule will vary depending on the level of usage and

environmental conditions. Once a month is a good starting point. Be sure to lubricate all friction points

completely. Use high temperature lithium grease. Key lubrication points are shown on the illustration below

for the latch system with the optional pushbutton combination lock. Some lube points in the illustration will

not be present on other latch systems. (See figure 4)

If the latch handle is removed or has been bumped out of alignment it will need to be adjusted correctly

again. The gap shown between the knob and the stop is critical and can vary slightly. If the gap is too small

the knob cannot be turned enough to unlock the latch. If the gap is too large then the knob can be turned

past its stop point which trips the internal clutch and will not unlock the latch. Adjust the handle so the gap