Top Flite TOPA0215 User Manual

Page 32

- 32 -

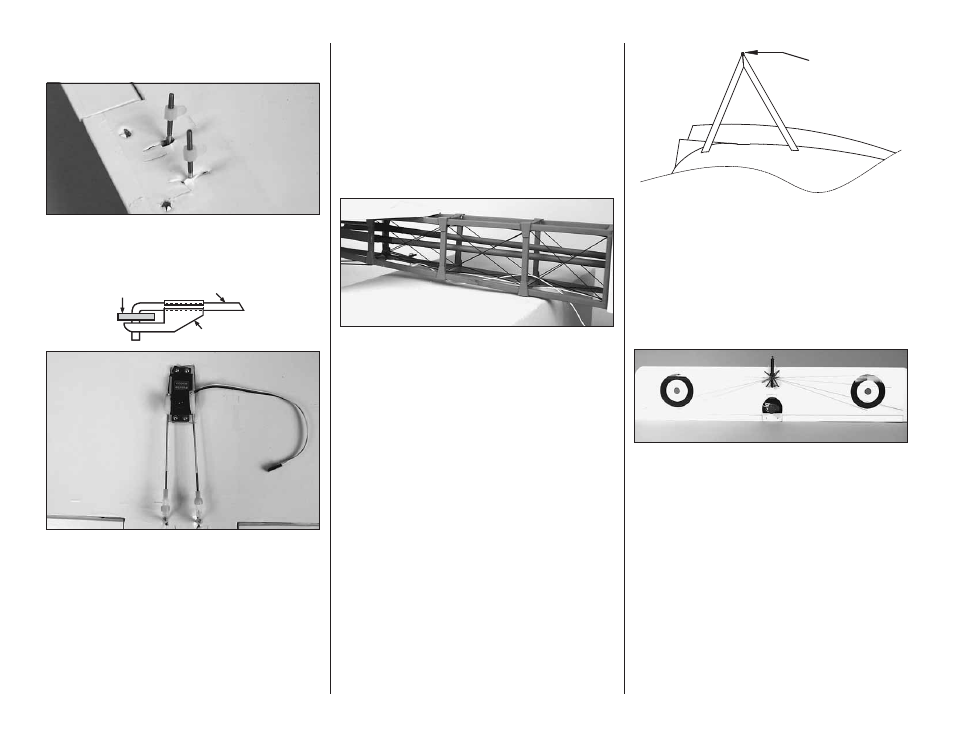

Install the Aileron Pushrods and

Control Horns

❏

1. Locate the two nylon torque rod connectors.

Screw them onto the aileron torque rods approximately

half way down the threaded rod.

FasLink

2-56 (.074") Pushrod Wire

Servo Arn

❏

2. Locate two 6" [152mm] .072 wire pushrods

threaded on one. Put a silicone clevis keeper over

each of the wires. Install a nylon clevis on each wire

approximately 20 turns and then install the clevis

onto the torque rod connector. Center the ailerons

and the servo arm. Align the wires under the arms of

the servo arm, mark the location where it crosses the

hole in the arm and then bend the wire on the mark.

Install the wire onto the servo arm with a nylon

Faslink. Cut off any excess wire extending beyond

the Faslink more than 1/16" [1.6mm].

Scale Details

Looking at the photo on the box you will see that we

added a few extra details to our model. They are not

necessary for any structural integrity but we felt they

added a bit of nostalgic detail that you might want to

consider adding to your model.

Kingposts and Flying Wires

❏

1. The open area at the rear of the fuselage has the

appearance of being rigged with wire. You could choose

to actually rig this area with a lightweight wire but we

used an elastic cord that you can easily obtain from a

fabric store. (This round cord is often used for making

elastic cuffs in a sleeve or pant leg). The benefit of the

elastic is that they always stay under tension and do not

sag like wire can, plus they are much easier to install.

Start by gluing one end of the elastic cord to one corner

with CA glue. With a little tension, pull the cord to the

next corner and glue it in place. Continue this until you

have formed an “X” pattern inside each of the formers

on the top, bottom and side.

❏

2. On the top of the wing and the bottom of the

fuselage we have installed the kingposts. The kingpost

on top of the wing are made from four 1/4" x 4-1/2"

[6mm x 115mm] hardwood dowels (not included in

the kit). The kingpost on the bottom of the fuselage is

made from four 1/4" x 2-1/2" [6mm x 64mm] dowels.

The dowels are cut at an angle and glued together

where the four dowels meet. The bottom of the post

is sanded to match the surface of the wing/fuselage.

The dowels should be glued together and glued to

the wing/fuselage with 6-minute epoxy.

Cotter pin

❏

3. The flying wires are also made from the same

elastic cord and the installation is similar to the tail

structure. Drill a small hole in the top of the kingpost

on the wing. Make the hole large enough to accept a

small cotter pin. We used a small brass cotter pin

from a Robart hinge but you can also find small ones

in a hardware store. Glue the cotter pin into the

Kingpost so that the small loop faces out towards

each wing tip.

❏

4. You may recall when building the wing that there

were four blocks installed in each wing half to attach the

wire to. Locate the previously drilled 1/16" [1.6mm] hole

in each of the blocks in the top of the wing. Punch a

hole in the covering with a T-pin through the hole in

each of the four blocks. Cut a piece of the elastic cord

that is long enough to reach from the blocks closest to

the leading edge of the wing. Apply a drop of thin CA to

the tip of the elastic cord and roll the tip in your finger.

The cord will stiffen from the glue and can then be

easily inserted into the hole in the block. Insert the

stiffened cord into the hole you drilled in the block.

Apply a drop of thin CA to keep it in place. Feed the

cord through the cotter pin in the top of the kingpost and

then stiffen the end of the cord and insert it into the hole

in the other wood block. Repeat this for all four wires in

the top of each wing half.