Top Flite TOPA0215 User Manual

Page 12

- 12 -

Finish the Bottom of the Wing

❏

❏

1. For the right wing panel, locate a 3/32" x

1-1/8" x 30" [2.4 x 28 x 760mm] balsa bottom leading

edge sheet. Cut it to a length of 29-3/4" [756mm].

Bevel one edge of the sheet as you did with the

sheeting on the top of the wing. When you are

satisfied with the fit, glue the sheeting in place on the

bottom of the wing.

❏

❏

2. Locate a 3/32" x 1" x 30" [2.4 x 25 x 760mm]

balsa bottom trailing edge sheet. Cut it to a length of

29-3/4" [756mm]. Glue it in place on the trailing edge

of the bottom of the wing.

❏

❏

3. Sheet the center section of the bottom wing

following the same procedure you used for sheeting

the center section on the top of the wing.

❏

❏

4. From 3/32" x 1/4" x 36" [2.4 x 6.4 x 914mm]

balsa sticks, cut nine cap strips. Cut each one to fit

between the leading edge sheeting and the trailing

edge sheeting on each rib.

You now need to make a decision. When the Elder

was originally introduced it had flying and landing

wires on it. Though these wires are not a structural

part of this model, they do add a great “Vintage” look

to the model. If you have ever installed wires and

turnbuckles you know there is some additional work

and cost to do this. For our model we used elastic

cord to simulate the flying wires. This was much

easier and less expensive than using actual wire. We

will give complete instructions for installing wire or

elastic flying wires as we get further into the building

process. If you choose not to install any of the wires

skip steps 5 & 6.

❏

❏

5. On the wing plan there are four locations

shown for 3/8” x 3/8” [9.5 x9.5mm] basswood blocks.

The blocks are provided in the kit and are cut to the

lengths shown on the plan. If you plan to install wire

and turnbuckles on your model, proceed with

installing the basswood blocks as shown on the plan.

If you choose to use the elastic cord as we did on our

model then you can substitute balsa blocks for the

basswood. The balsa is a little easier to work with

than the basswood and will retain the elastic cord

better than the basswood. Locate the 3/8” x 3/8” x 18”

[9.5 x 9.5 x 457mm] balsa stick and cut it to the

length specified on the plan for each of the four

blocks. Glue the blocks on the positions shown on

the plan.

❏

❏

6. Whether you have installed the balsa or

basswood blocks, drill a 1/16" [1.6mm] hole through

the center of the entire length of the block.

❏

❏

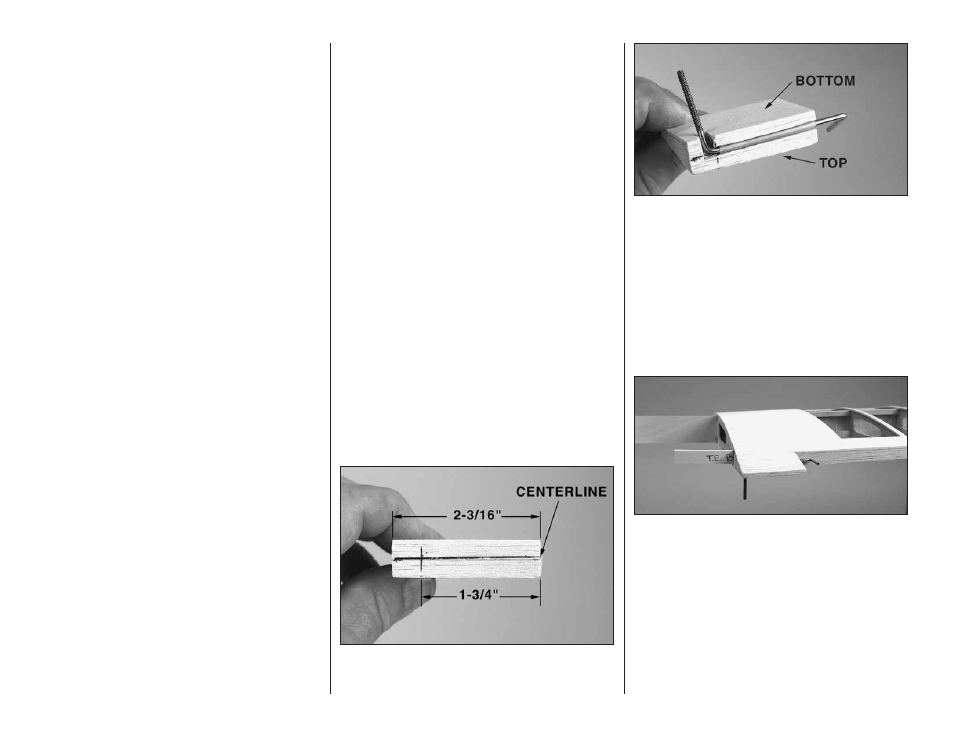

7. Locate the 30" [762mm] shaped balsa

aileron. From one end of the aileron cut a piece

2-3/16" [55.8mm] in length.

❏

❏

8. Mark a centerline on this piece of aileron

stock. Make another mark 1-3/4" [44mm] from the

end of the block.

❏

❏

9. Cut a slot as shown in the photo along the

centerline starting at the end. The slot needs to be

1/8" [ 3mm] wide to accommodate the torque rod.

The slot can be cut easily with the Great Planes®

Groove Tube™ (GPMR8140) or the slot can be cut

with your hobby knife. Notice that these blocks are

not symmetrical so make the one for the left wing the

mirror image of this one.

❏

❏

10. Cut another slot perpendicular to the slot you

just cut to accommodate the arm of the torque rod.

❏

❏

11. Glue the block with the torque rod in place

in the slot, being careful not to get any glue onto the

metal wire. Tip – Apply a small amount of petroleum

jelly to the end of the plastic bearing. This will prevent

glue from getting onto the wire. Important! Before

gluing the block in place be sure that you have the

correct torque rod in place in the block. The

un-threaded arm of the torque rod should protrude

into the area where the aileron will be attached. The

threaded end of the arm will protrude towards the

bottom of the wing. Make sure that you install the

correct rod for each wing half.