Top Flite TOPA0215 User Manual

Page 22

- 22 -

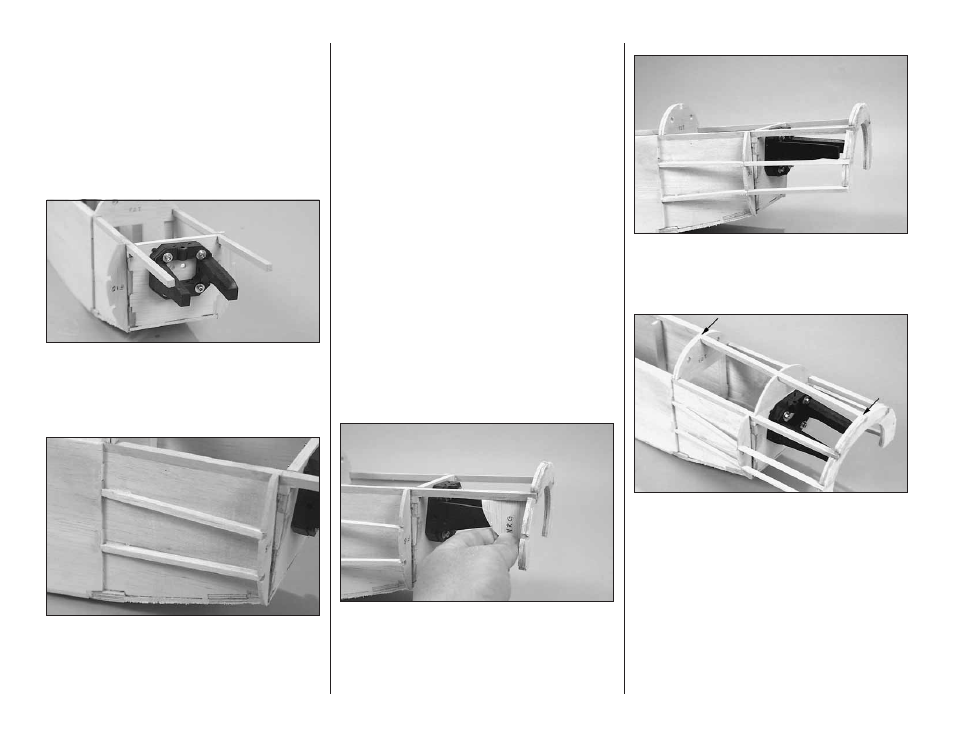

washers and four #6 lock washers. Temporarily place

your engine in the mount to set the width of the

mounting rails to fit your engine. Remove the engine

and tighten all the engine mount mounting bolts. For

our model we will be installing the engine inverted so

we have installed the engine mount inverted. Be sure to

properly install your engine mount for the position you

choose to install your motor. Drill two 3/16" [4.8mm]

holes in the firewall to accommodate the fuel line and

the engine pressure line from the fuel tank.

❏

5. Locate the two die-cut 1/8" [3mm] balsa F1S

formers. Glue them in position on both the left and

right side of the fuselage. Use the lines you have

drawn on the sides of the fuselage as reference for

gluing them in place.

❏

6. From a 3/16" x 3/16" x 36" [4.8 x4.8 x 914mm]

balsa stick cut the balsa side stringers. Sand a bevel

on the end of the sticks that are glued flush to the

fuselage side. Cut the sticks to length so they fit to

the middle of former F1S and glue them in place.

❏

7. Locate the two die-cut 1/8" [3mm] plywood nose

rings. Glue them together to form one 1/4" [6mm]

plywood nose ring.

❏

8. You are now going to install the nose ring to the

fuselage. The positioning of the nose ring is

determined by the length of your engine. Temporarily

position your engine onto the engine mount. (Do not

permanently mount your engine to the mount).

Determine where the nose ring will be positioned so

when the engine is installed the front of the engine

thrust washer is approximately 1/4" - 3/8" [6mm –

9mm] further forward than the nose ring. Mark the

location of the nose ring on the basswood rails.

❏

9. Insert the nose ring onto the basswood rails.

Locate the die-cut 1/8" [3mm] nose ring gauge

(NRG). Use it to set the angle of the nose ring as

shown. Glue the nose ring to the rails. If there is any

of the basswood rail extending beyond the nose ring,

cut it off flush with the nose ring.

❏

10. From the remainder of the 3/16" x 3/16" x 36"

[4.8 x4.8 x 914mm] balsa stick, cut, fit and glue the

remaining side stringers from F1S to the nose ring.

Do this for both sides of the fuselage.

❏

11. From a leftover 1/4" x 1/4" [6 x 6mm] basswood

stick, cut a stick for the center fuselage stringer to fit

from former F2T to the front of the nose ring. Glue it

in position. Glue the die-cut 1/8" [3mm] plywood

former F1T to the top of F1. Slide it forward or aft

slightly to fit under the basswood stick.

❏

12. You are now going to sheet the front of the

fuselage. This is going to require compound bends to

the sheeting. To accomplish this you must wet the

wood before gluing it into place. Rubbing alcohol

misted onto the wood with a spray bottle works best

but you can also accomplish the task with water.