Top Flite TOPA0215 User Manual

Page 31

- 31 -

Install the Elevator, Rudder Pushrods

and Control Horns

❏

1. Locate the two 5/16" x 36" [7.9 x 914mm] wood

dowels. These will be the elevator and rudder pushrods.

Cut each of them to 24-1/2" [623mm] in length.

❏

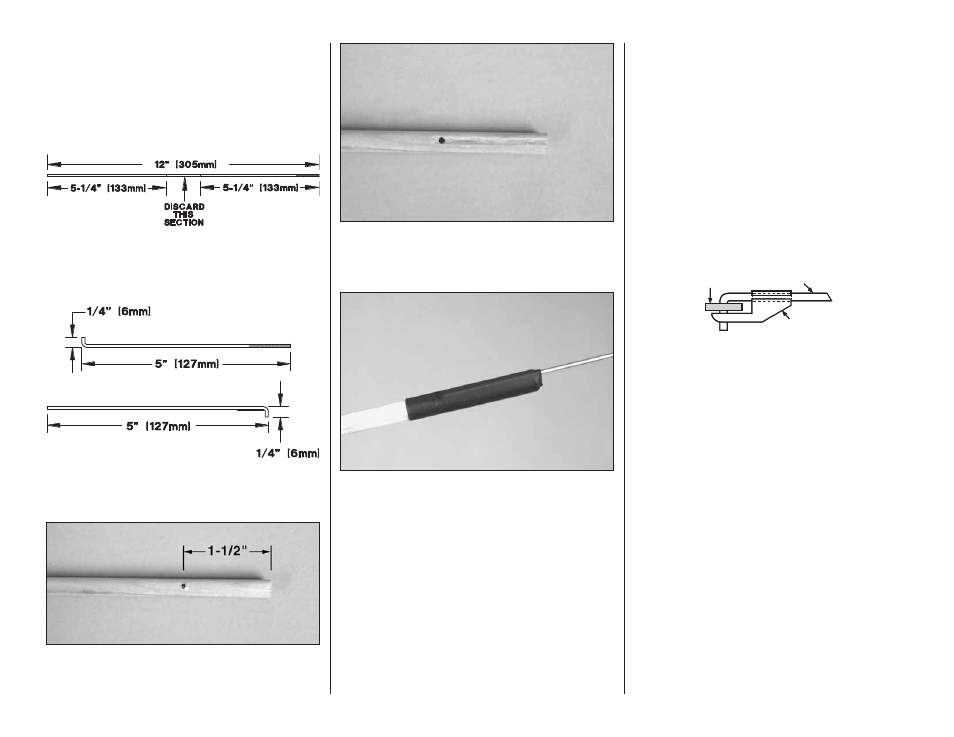

2. Locate two .074 x 12" [1.9 x 305mm] wires

threaded on one end. Cut them as shown in the sketch.

❏

3. Bend each of the wires as shown, making two

sets of wires as shown in the sketch.

❏

4. From each end of the dowel measure in 1-1/2"

[38mm]. Drill a 5/64" [2mm] hole on the mark, drilling

through the dowel.

❏

5. From the end of the dowel to the hole, cut a slot

the width of the hole.

❏

6. Insert the end of the rod with the 1/4" [6mm] bend

into the dowel. Insert the threaded rod into one end and

the un-threaded rod into the other. Apply a small

amount of thin CA to the rod and the dowel. Then allow

it to cure. Cut two pieces of heat shrink tubing to 2"

[51mm] in length, slide the heat shrink tubing over each

end of the dowel and then shrink it tight onto each of

the pushrod wires. Do this for both pushrods.

❏

7. If you would like the pushrods to match the rear

structure of the fuselage, paint or stain them to

match. If you will be painting them, mask off the heat

shrink tubing. Paint will not stick to it very well.

❏

8. Reference the plan to locate the position for the

nylon control horn on the bottom of the elevator.

Mark the location for the screw holes for the control

horn. Drill a 3/32" [2.4mm] hole through the elevator

on each of these marks then harden the holes with a

couple of drops of thin CA.

❏

9. Install the control horn onto the bottom of the

elevator. Install the two 2-56 machine screws through

the control horn and the control horn plate on the top

of the elevator.

❏

10. Repeat steps 9 and 10 for installing the control

horn on the rudder.

FasLink

2-56 (.074") Pushrod Wire

Servo Arn

❏

11. Put a silicone clevis keeper over the threaded

end of the elevator wire then install the clevis onto

the wire approximately 20 turns. Connect the clevis

to the control horn. Center the elevator and the servo

arm. Align the wire under the arm of the servo horn,

mark the location where it crosses the hole in the

arm and then bend the wire on the mark. Install the

wire onto the servo horn arm with a nylon Faslink.

Cut off any excess wire extending beyond the Faslink

more than 1/16" [1.6mm].

❏

12. Repeat step 11 for the rudder pushrod.