Top Flite TOPA0215 User Manual

Page 30

- 30 -

Join the Control Surfaces

❏

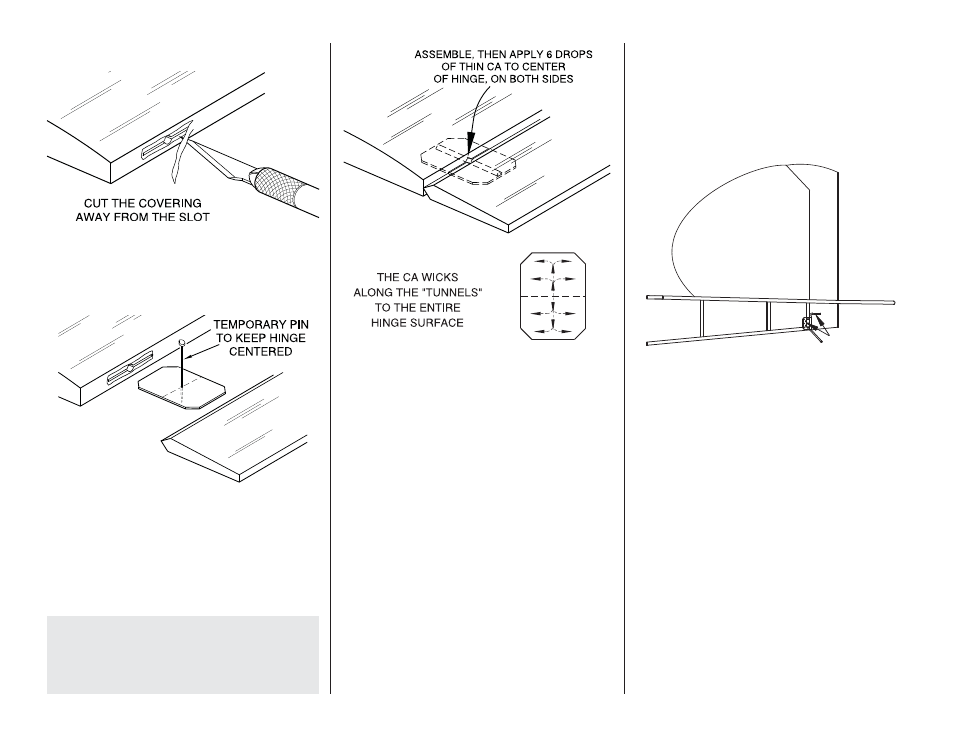

1. Start with the stab and elevator. Remove a small

strip of covering from the hinge slots.

❏

2. Test fit the hinges in only the stab or elevators

(without glue).

❏

3. Join the elevators to the stab with the hinges. If

the hinges don’t remain centered as you join the

elevators to the stab, remove the elevators and insert

a pin in the center of the hinges to keep them

centered. Make sure there is approximately a 1/64"

[.5mm] gap between the elevators and the stab so

you do not glue them together.

Do not use CA accelerator on any of the hinges

and do not glue the hinges with anything but thin

CA. Do not attempt to glue one half of the hinge

at a time. The hinges will not be properly secured

and could come out while the model is in flight.

❏

4. Cut a paper towel into 2" [50mm] squares. Add

six drops of thin CA to the center of the hinges on

both the top and bottom. The tunnels you drilled will

wick the CA into the entire hinge surface. Use the

paper towel squares to absorb excess CA from the

hinge gap before it cures.

If you have chosen to install the tailwheel assembly

instead of the tail skid, skip step 5 and follow steps

6-10. If you chose the tail skid, step 5 completes the

instructions for joining the control surfaces.

❏

5. Use the same hinging method to join the rudder to

the fin and the ailerons to the wing. When installing the

ailerons be sure the aileron torque rod wire is firmly

glued into the hole in the aileron with 6-minute epoxy.

The following steps are used only if you are using a

tail wheel.

❏

6. Trial fit the hinges and the tail wheel wire into

the rudder. Trial fit the rudder to the stab inserting the

hinges into the hinge slots and the nylon tail wheel

bearing into the slot in the fuselage cross bracing.

Epoxy

❏

7. When you are satisfied with the fit remove the

rudder from the fin. Apply epoxy to the portion of the

tail wheel wire that fits into the rudder then slide the

wire into the rudder. Be careful not to get any epoxy

into the tail wheel bearing. Hint: A small amount of

petroleum jelly applied to the area where the wire

passes through the bearing will prevent glue from

getting into the bearing.

❏

8. Apply epoxy onto the nylon bearing where it will

be inserted into the cross bracing. Apply some epoxy

in the slot in the cross bracing as well. Insert the

rudder assembly into the fin. When you are satisfied

with the fit, wipe away any excess epoxy and then

apply thin CA to the hinges the same as you did for

the elevator.

❏

9. Install the 1" [25mm] tail wheel (not included)

onto the wire with two 3/32" [2.4mm] wheel collars

and two 4-40 set screws.