Service, Filters, Water coil – Carrier AQUAZONE PCV015-060 User Manual

Page 38: Condensate drain pans, Refrigerant system, Compressor, Fan motors, Condensate drain cleaning, Air coil cleaning

38

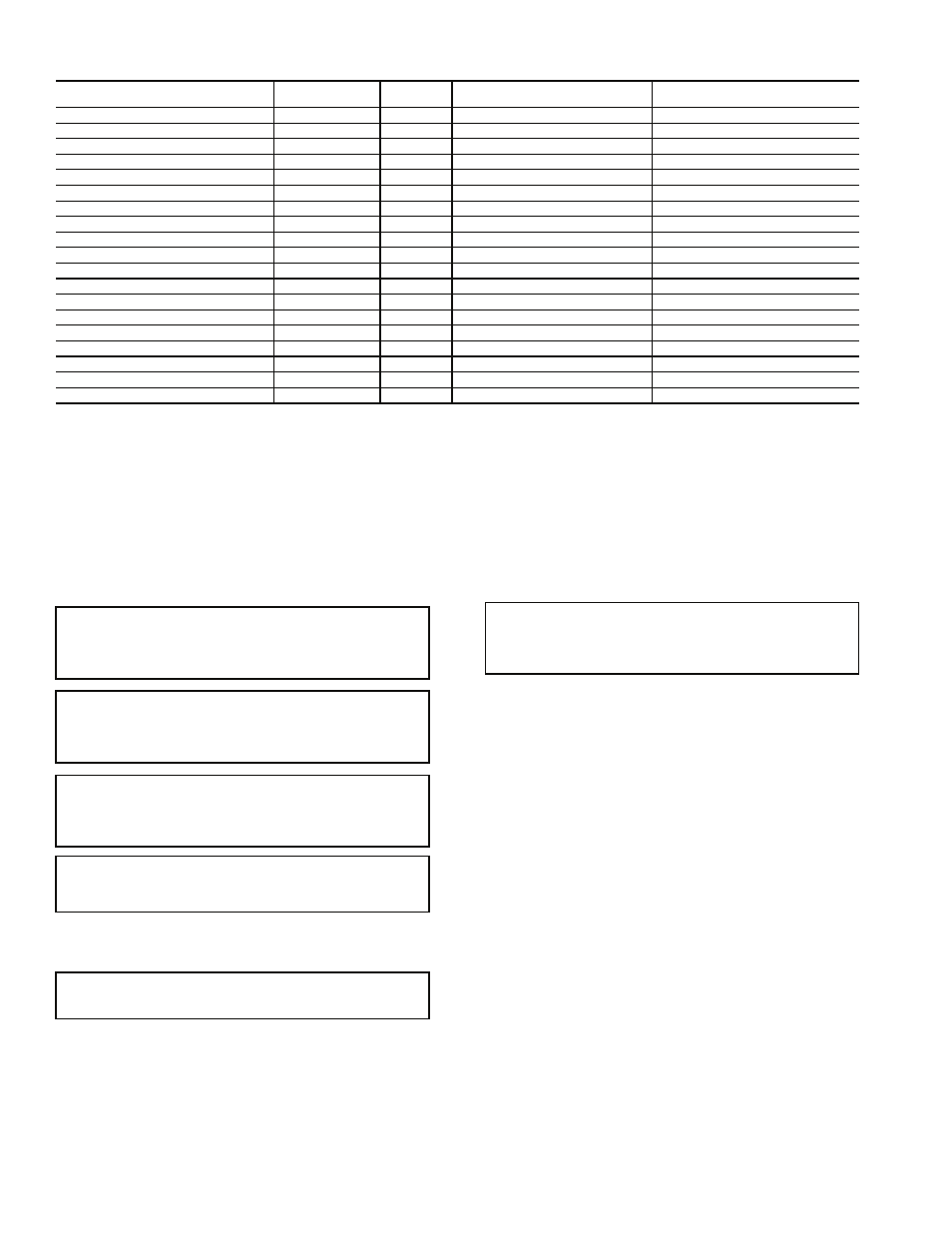

Table 28 — Aquazone Deluxe D Control Current LED Status and Alarm Relay Operations

LEGEND

NOTES:

1. If there is no fault in memory, the Fault LED will flash code 1.

2. Codes will be displayed with a 10-second Fault LED pause.

3. Slow flash is 1 flash every 2 seconds.

4. Fast flash is 2 flashes every 1 second.

5. EXAMPLE: “Flashing Code 2” is represented by 2 fast flashes followed by a

10-second pause. This sequence will repeat continually until the fault is

cleared.

SERVICE

Perform the procedures outlined below periodically, as

indicated.

Filters —

Filters must be clean for maximum performance.

Inspect filters every month under normal operating conditions.

Replace when necessary.

Water Coil —

Keep all air out of the water coil. Check

open loop systems to be sure the well head is not allowing air

to infiltrate the water line. Always keep lines airtight.

Inspect heat exchangers regularly, and clean more frequent-

ly if the unit is located in a “dirty” environment. Keep the heat

exchanger full of water at all times. Open-loop systems should

have an inverted P trap placed in the discharge line to keep

water in the heat exchanger during off cycles. Closed-loop

systems must have a minimum of 15 psig during the summer

and 40 psig during the winter. Generally, the higher the water

flow through the bail, the lower the chance for sealing.

Check P trap frequently for proper operation.

Condensate Drain Pans —

Check condensate drain

pans for algae growth twice a year. If algae growth is apparent,

consult a water treatment specialist for proper chemical treat-

ment. Applying an algaecide every three months will typically

eliminate algae problems in most locations.

Refrigerant System —

Verify air and water flow rates

are at proper levels before servicing. To maintain sealed circuit-

ry integrity, do not install service gauges unless unit operation

appears abnormal.

Check to see that unit is within the superheat and subcool-

ing temperature ranges shown in Tables 16-22. If the unit is not

within these ranges, recover and reweigh in refrigerant charge.

Compressor —

Conduct annual amperage checks to en-

sure that amp draw is no more than 10% greater than indicated

on the serial plate data.

Fan Motors —

All units have lubricated fan motors. Fan

motors should never be lubricated unless obvious, dry opera-

tion is suspected. Periodic maintenance oiling is NOT recom-

mended as it will result in dirt accumulating in the excess oil

and cause eventual motor failure. Conduct annual dry opera-

tion check and amperage check to ensure amp draw is no more

than 10% greater than indicated on serial plate data.

Condensate Drain Cleaning —

Clean the drain line

and unit drain pan at the start of each cooling season. Check

flow by pouring water into drain. Be sure trap is filled to main-

tain an air seal.

Air Coil Cleaning —

Remove dirt and debris from evap-

orator coil as required by condition of the coil. A 10% solution

DESCRIPTION

STATUS LED

(Green)

TEST LED

(Yellow)

FAULT LED (Red)

ALARM RELAY

Normal Mode

On

Off

Flash Last Fault Code in Memory

Open

Normal Mode with PM

On

Off

Flashing Code 8

Cycle (closed 5 sec, open 25 sec, …)

Deluxe D Control is non-functional

Off

Off

Off

Open

Test Mode

—

On

Flash Last Fault Code in Memory

Cycling Appropriate Code

Night Setback

Flashing Code 2

—

Flash Last Fault Code in Memory

—

ESD

Flashing Code 3

—

Flash Last Fault Code in Memory

—

Invalid T-stat Inputs

Flashing Code 4

—

Flash Last Fault Code in Memory

—

No Fault in Memory

On

Off

Flashing Code 1

Open

HP Fault

Slow Flash

Off

Flashing Code 2

Open

LP Fault

Slow Flash

Off

Flashing Code 3

Open

FP1 Fault

Slow Flash

Off

Flashing Code 4

Open

FP2 Fault

Slow Flash

Off

Flashing Code 5

Open

CO Fault

Slow Flash

Off

Flashing Code 6

Open

Over/Under Voltage

Slow Flash

Off

Flashing Code 7

Open (closed after 15 minutes)

HP Lockout

Fast Flash

Off

Flashing Code 2

Closed

LP Lockout

Fast Flash

Off

Flashing Code 3

Closed

FP1 Lockout

Fast Flash

Off

Flashing Code 4

Closed

FP2 Lockout

Fast Flash

Off

Flashing Code 5

Closed

CO Lockout

Fast Flash

Off

Flashing Code 6

Closed

CO

— Condensate Overflow

HP

—

High Pressure

ESD

— Emergency Shutdown

LP

—

Low Pressure

FP

— Freeze Protection

PM

—

Performance Monitor

IMPORTANT: When a compressor is removed from this

unit, system refrigerant circuit oil will remain in the com-

pressor. To avoid leakage of compressor oil, the refrigerant

lines of the compressor must be sealed after it is removed.

IMPORTANT: All refrigerant discharged from this unit

must be recovered without exception. Technicians must fol-

low industry accepted guidelines and all local, state and fed-

eral statutes for the recovery and disposal of refrigerants.

IMPORTANT: To avoid the release of refrigerant into the

atmosphere, the refrigerant circuit of this unit must only be

serviced by technicians who meet local, state and federal

proficiency requirements.

IMPORTANT: To prevent injury or death due to electrical

shock or contact with moving parts, open unit disconnect

switch before servicing unit.

IMPORTANT: Units should never be operated with-

out a filter.

IMPORTANT: To avoid fouled machinery and extensive

unit clean-up, DO NOT operate units without filters in

place. DO NOT use equipment as a temporary heat source

during construction.