Carrier AQUAZONE PCV015-060 User Manual

Page 10

10

Insulation is not required on loop water piping except where

the piping runs through unheated areas or outside the building

or when the loop water temperature is below the minimum ex-

pected dew point of the pipe ambient. Insulation is required if

loop water temperature drops below the dew point.

Pipe joint compound is not necessary when Teflon threaded

tape is pre-applied to hose assemblies or when flared-end

connections are used. If pipe joint compound is preferred, use

compound only in small amounts on the male pipe threads of

the fitting adapters. Prevent sealant from reaching the flared

surfaces of the joint.

NOTE: When anti-freeze is used in the loop, assure that it is

compatible with Teflon tape or pipe joint compound employed.

Maximum allowable torque for brass fittings is 30 ft-lb. If a

torque wrench is not available, tighten finger-tight plus one

quarter turn. Tighten steel fittings as necessary.

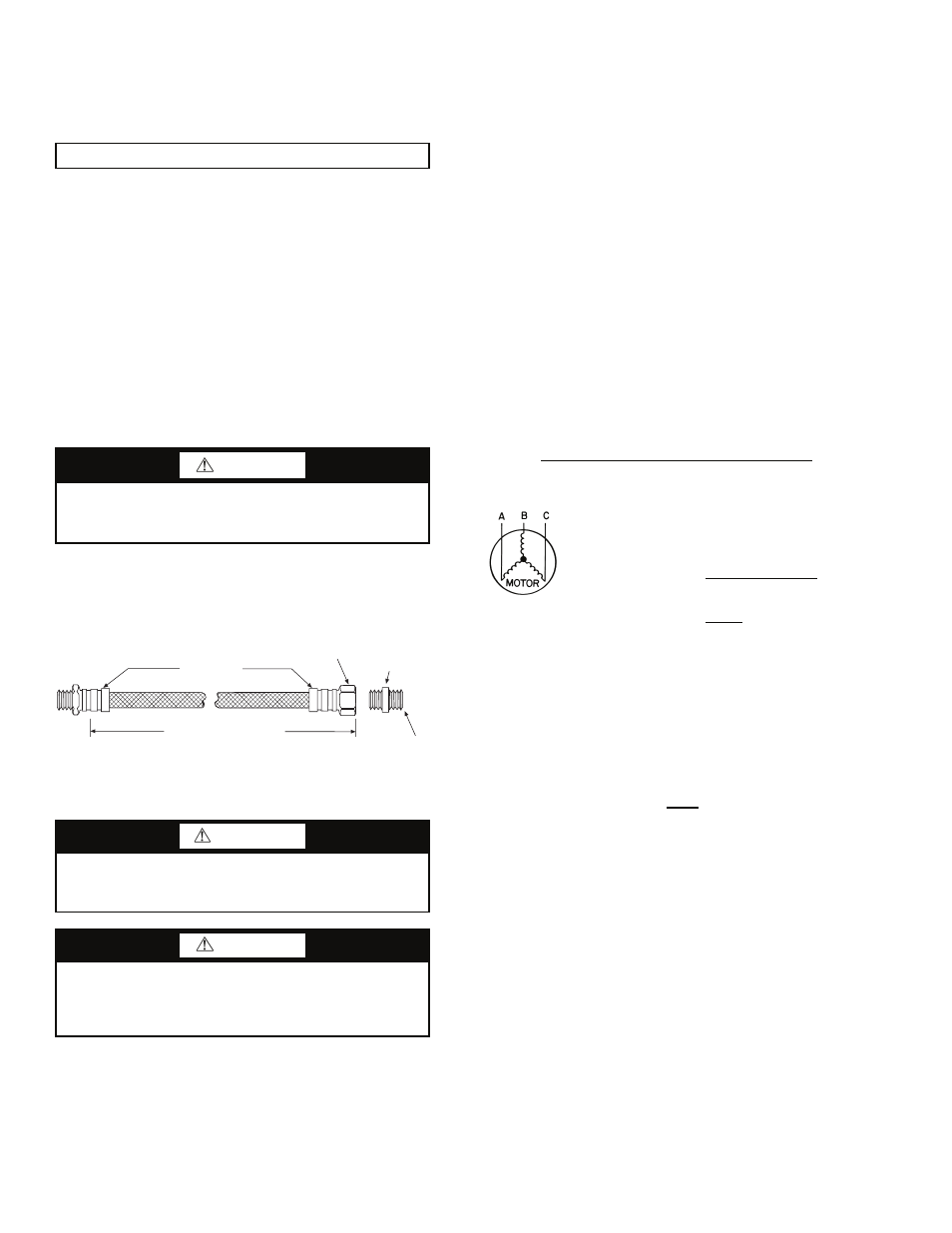

Optional pressure-rated hose assemblies designed specifi-

cally for use with Carrier units are available. Similar hoses can

be obtained from alternate suppliers. Supply and return hoses

are fitted with swivel-joint fittings at one end to prevent kink-

ing during installation.

Refer to Fig. 12 for an illustration of a supply/return hose

kit. Male adapters secure hose assemblies to the unit and risers.

Install hose assemblies properly and check them regularly to

avoid system failure and reduced service life.

Step 8 — Wire Field Power Supply

All field installed wiring, including the electrical ground,

MUST comply with the National Electrical Code (NEC) as

well as applicable local codes. In addition, all field wiring must

conform to the Class II temperature limitations described in the

NEC.

Refer to unit wiring diagrams Fig. 13-22 for a schematic of

the field connections, which must be made by the installing (or

electrical) contractor. Refer to Table 3 for fuse sizes.

Consult the unit wiring diagram located on the inside of the

compressor access panel to ensure proper electrical hookup.

The installing (or electrical) contractor must make the field

connections when using field-supplied disconnect.

Operating voltage must be the same voltage and phase as

shown in Table 3.

Make all final electrical connections with a length of flexi-

ble conduit to minimize vibration and sound transmission to

the building.

POWER CONNECTION — Make line voltage connection

by connecting the incoming line voltage wires to the L side

of the CC terminal as shown in Fig. 23. See Table 3 for cor-

rect wire and maximum overcurrent protection sizing.

SUPPLY VOLTAGE — Operating voltage to unit must be

within voltage range indicated on unit nameplate.

On 3-phase units, voltages under load between phases must

be balanced within 2%. Use the following formula to deter-

mine the percentage voltage imbalance:

% Voltage Imbalance

Example: Supply voltage is 460-3-60.

AB = 452 volts

BC = 464 volts

AC = 455 volts

Determine maximum deviation from average voltage:

(AB) 457 – 452 = 5 v

(BC) 464 – 457 = 7 v

(AC) 457 – 455 = 2 v

Maximum deviation is 7 v.

Determine percent voltage imbalance.

This amount of phase imbalance is satisfactory as it is

below the maximum allowable 2%.

Operation on improper line voltage or excessive phase

imbalance constitutes abuse and may cause damage to electri-

cal components.

NOTE: If more than 2% voltage imbalance is present, contact

your local electric utility.

208-VOLT OPERATION — All 208-230 volt units are factory

wired for 208 volts. The transformers may be switched to

230-volt operation by switching the red (208 volt) wire with

the orange (230 volt) wire at the L1 terminal.

460-VOLT OPERATION — Units using 460-v and internal

secondary pump will require a neutral wire from the supply

side in order to feed accessory with 265-v.

IMPORTANT: Do not bend or kink supply lines or hoses.

CAUTION

Backup wrench is required when tightening water connec-

tions to prevent water line damage. Failure to use a backup

wrench could result in equipment damage.

WARNING

To avoid possible injury or death due to electrical shock,

open the power supply disconnect switch and secure it in

an open position during installation.

CAUTION

Use only copper conductors for field-installed electrical

wiring. Unit terminals are not designed to accept other

types of conductors. Failure to follow this safety precaution

could lead to equipment damage.

= 100 x

max voltage deviation from average voltage

average voltage

Average Voltage =

452 + 464 + 455

3

=

1371

3

= 457

% Voltage Imbalance = 100 x

7

457

= 1.53%

Rib Crimped

Length

(2 ft Length Standard)

Swivel

Brass

Fitting

Brass

Fitting

MPT

Fig. 12 — Supply/Return Hose Kit

A50-7734