Carrier AQUAZONE PCV015-060 User Manual

Page 24

24

Wiring a Supply Air Temperature (SAT) Sensor — The

SAT sensor is required for reheat applications.

If the cable used to wire the SAT sensor to the controller

will be less than 100 ft, an unshielded 22 AWG (American

Wire Gage) cable should be used. If the cable will be greater

than 100 ft, a shield 22 AWG cable should be used. The cable

should have a maximum length of 500 ft.

To wire the SAT sensor to the controller:

1. Wire the sensor to the controller. See Fig. 18-22.

2. Verify that the Enable SAT jumper is on.

3. Verify that the Enable SAT and Remote jumper is in the

left position.

Wiring an Indoor Air Quality (IAQ) Sensor — An IAQ

sensor monitors CO

2

levels. The WSHP Open controller uses

this information to adjust the outside-air dampers to provide

proper ventilation. An IAQ sensor can be wall-mounted or

mounted in a return air duct. (Duct installation requires an aspi-

rator box assembly.)

The sensor has a range of 0 to 2000 ppm and a linear 4 to

20 mA output. This is converted to 1 to 5 vdc by a 250-ohm,

1

/

4

watt, 2% tolerance resistor connected across the zone con-

troller’s IAQ input terminals.

NOTE: Do not use a relative humidity sensor and CO

2

sensor

on the same zone controller if both sensors are powered off the

board. If sensors are externally powered, both sensors may be

used on the same zone controller.

If the cable used to wire the IAQ sensor to the controller

will be less than 100 ft, an unshielded 22 AWG (American

Wire Gage) cable should be used. If the cable will be greater

than 100 ft, a shield 22 AWG cable should be used. The cable

should have a maximum length of 500 ft.

To wire the IAQ sensor to the controller:

1. Wire the sensor to the controller. See Fig. 18-22.

2. Install a field-supplied 250-ohm,

1

/

4

watt, 2% tolerance

resistor across the controller’s RH/IAQ and Gnd

terminals.

3. Verify the the RH/IAQ jumper is set to 0 to 5-vdc.

Wiring a Relative Humidity (RH) Sensor — The RH sensor

is used for zone humidity control (dehumidification) if the

WSHP unit has a dehumidification device. If not, the sensor

only monitors humidity.

NOTE: Do not use a relative humidity sensor and CO

2

sensor

on the same zone controller if both sensors are powered off the

board. If sensors are externally powered, both sensors may be

used on the same zone controller.

If the cable used to wire the RH sensor to the controller will

be less than 100 ft, an unshielded 22 AWG (American Wire

Gage) cable should be used. If the cable will be greater than

100 ft, a shield 22 AWG cable should be used. The cable

should have a maximum length of 500 ft.

To wire the RH sensor to the controller:

1. Strip the outer jacket from the cable for at least 4 inches.

2. Strip

1

/

4

in. of insulation from each wire.

3. Wire the sensor to the controller.

PRE-START-UP

System Checkout —

When the installation is complete,

follow the system checkout procedure outlined below before

starting up the system. Be sure:

1. Voltage is within the utilization range specifications of the

unit compressor and fan motor and voltage is balanced

for 3 phase units.

2. Fuses, breakers and wire are correct size.

3. Low voltage wiring is complete.

4. Piping and system flushing is complete.

5. Air is purged from closed loop system.

6. System is balanced as required. Monitor if necessary.

7. Isolation valves are open.

8. Water control valves or loop pumps are wired.

9. Condensate line is open and correctly pitched.

10. Transformer switched to lower voltage tap if necessary.

11. Blower rotates freely — shipping support is removed.

12. Blower speed is on correct setting.

13. Air filter is clean and in position.

14. Service/access panels are in place.

15. Return-air temperature is between 40 to 80 F heating and

50 to 110 F cooling.

16. Air coil is clean.

17. Control field-selected settings are correct.

AIR COIL — To obtain maximum performance, clean the air

coil before starting the unit. A ten percent solution of dish-

washer detergent and water is recommended for both sides of

the coil. Rinse thoroughly with water.

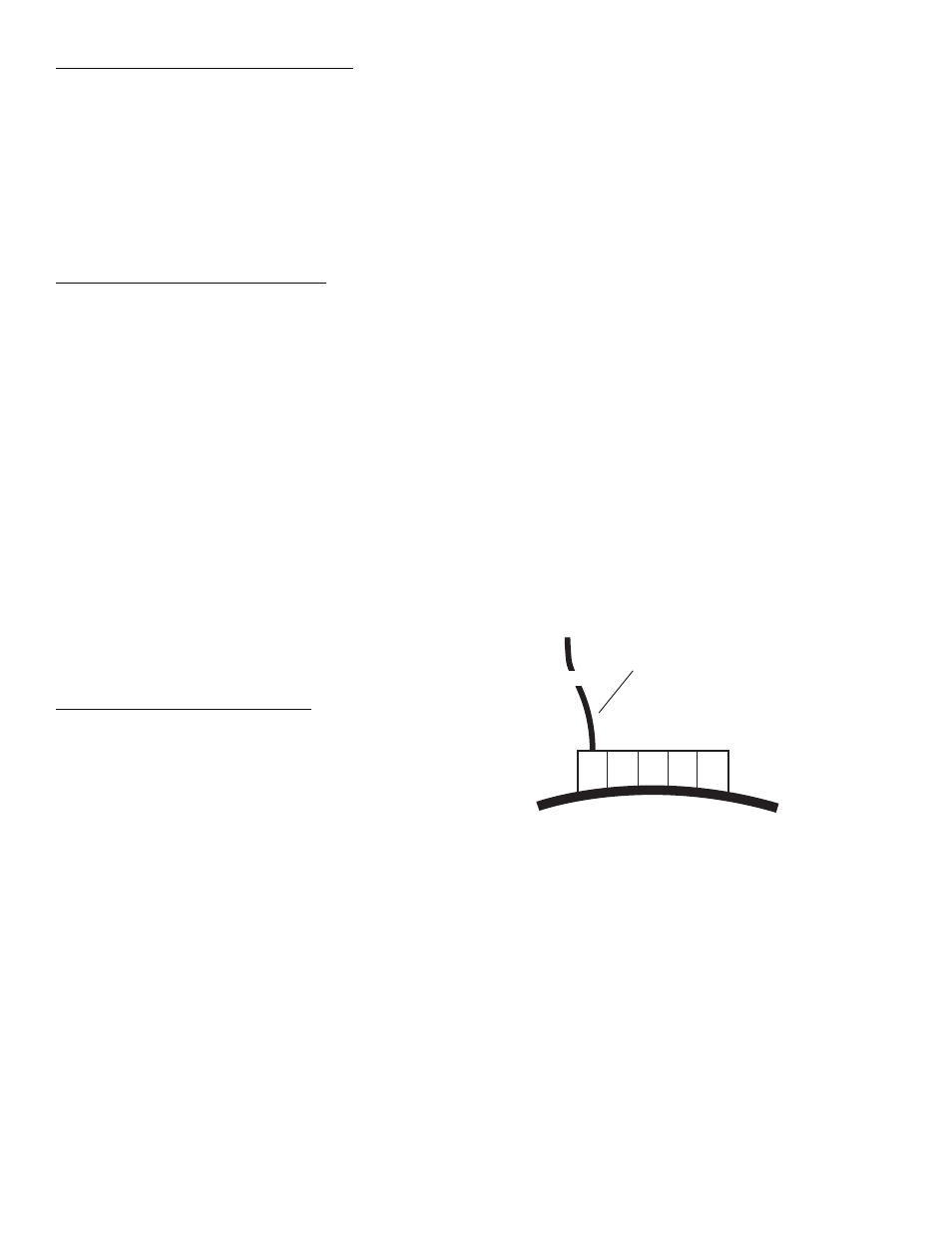

PSC (Permanent Split Capacitor) Blower

Speed Selection —

All water source heat pumps are

factory set to deliver rated airflow at nominal static (0.15 in.

wg) on medium speed. Where higher static is needed, high

speed can be utilized (0.4 to 0.5 in. wg). Low speed will

deliver approximately 85% of rated airflow (0.10 in. wg). The

PSC blower fan speed can be changed on all units by swapping

wires connected to the relay contacts that control the fan. See

Fig. 30.

The PSC blower fan speed can be changed by moving the blue

wire on the fan motor terminal block to the desired speed as

shown in Fig. 30. The 50PC units are designed to deliver rated

airflow at nominal static (0.15 in. wg) on medium speed

(factory setting) and rated airflow at a higher static (0.4 to

0.5 in. wg) on high speed for applications where higher static is

required. Low speed will deliver approximately 85% of rated

airflow at 0.10 in. wg. An optional ‘high static’ blower is avail-

able by using the special option code in the model

nomenclature.

NOTE: Blower performance is shown in Tables 8-11.

CONNECT THE BLUE WIRE TO:

FAN MOTOR

MEDIUM FACTORY SETTING

H FOR HIGH SPEED FAN

M FOR MEDIUM SPEED FAN

L FOR LOW SPEED FAN

H

M

L

BLU

Fig. 30 — Blower Speed Selection