Flow regulation, Flushing, Warning – Carrier AQUAZONE PCV015-060 User Manual

Page 32

32

• The condenser water limit needs to be verified

depending on design parameters and application,

whether geothermal or boiler/tower.

7. To view unit configuration settings:

a. Select the Unit Configuration softkey, then select

Unit.

b. Scroll through the unit settings by using the up and

down arrow keys. Unit settings include:

• Fan Mode: Default Continuous

• Fan Delay:

• Minimum SAT Cooling: Default 50 F

• Maximum SAT Heating: Default 110 F

• Filter Service Alarm: Must be set from 0 to 9999 hr

8. To set local schedules:

a. Select the Schedule softkey from the Configuration

screen, then press enter.

b. Select Weekly, then press enter (7 schedules

available).

c. Select day and press enter.

d. Press enter again and select ADD or DEL (DECR

or INCR) set schedule.

e. Enter ON/OFF time, then press continue.

f. Press OK to apply and save to a particular day of

the week.

g. Continue to add the same or different schedule spe-

cific days of the week.

To add exceptions to the schedule:

i. Press Add softkey.

ii. Select exception type from following:

• Date

• Date Range

• Week-N-Day

• Calender Reference

9. Go back to Home Screen.

10. Remove BACview

6

cable from SPT sensor by reversing

the process in Step 1.

11. Perform system test.

Flow Regulation —

Flow regulation can be accom-

plished by two methods. Most water control valves have a flow

adjustment built into the valve. By measuring the pressure drop

through the unit heat exchanger, the flow rate can be deter-

mined. See Table 23. Adjust the water control valve until the

flow of 1.5 to 2 gpm is achieved. Since the pressure constantly

varies, two pressure gages may be needed in some

applications.

An alternative method is to install a flow control device.

These devices are typically an orifice of plastic material de-

signed to allow a specified flow rate that are mounted on the

outlet of the water control valve. Occasionally these valves

produce a velocity noise that can be reduced by applying some

back pressure. To accomplish this, slightly close the leaving

isolation valve of the well water setup.

Flushing —

Once the piping is complete, units require final

purging and loop charging. A flush cart pump of at least 1.5 hp

is needed to achieve adequate flow velocity in the loop to purge

air and dirt particles from the loop. Flush the loop in both

directions with a high volume of water at a high velocity. Fol-

low the steps below to properly flush the loop:

1. Verify power is off.

2. Fill loop with water from hose through flush cart before

using flush cart pump to ensure an even fill. Do not allow

the water level in the flush cart tank to drop below the

pump inlet line to prevent air from filling the line.

3. Maintain a fluid level in the tank above the return tee to

avoid air entering back into the fluid.

4. Shutting off the return valve that connects into the flush

cart reservoir will allow 50 psig surges to help purge air

pockets. This maintains the pump at 50 psig.

5. To purge, keep the pump at 50 psig until maximum

pumping pressure is reached.

6. Open the return valve to send a pressure surge through

the loop to purge any air pockets in the piping system.

7. A noticeable drop in fluid level will be seen in the flush

cart tank. This is the only indication of air in the loop.

NOTE: If air is purged from the system while using a 10 in.

PVC flush tank, the level drop will only be 1 to 2 in. since

liquids are incompressible. If the level drops more than this,

flushing should continue since air is still being compressed in

the loop. If level is less than 1 to 2 in., reverse the flow.

8. Repeat this procedure until all air is purged.

9. Restore power.

Antifreeze may be added before, during or after the flushing

process. However, depending on when it is added in the

process, it can be wasted. Refer to the Antifreeze section for

more detail.

Loop static pressure will fluctuate with the seasons. Pres-

sures will be higher in the winter months than during the

warmer months. This fluctuation is normal and should be con-

sidered when charging the system initially. Run the unit in

either heating or cooling for several minutes to condition the

loop to a homogenous temperature.

When complete, perform a final flush and pressurize the

loop to a static pressure of 40 to 50 psig for winter months or

15 to 20 psig for summer months.

After pressurization, be sure to remove the plug from the

end of the loop pump motor(s) to allow trapped air to be

discharged and to ensure the motor housing has been flooded.

Be sure the loop flow center provides adequate flow through

the unit by checking pressure drop across the heat exchanger.

Compare the results to the data in Table 23.

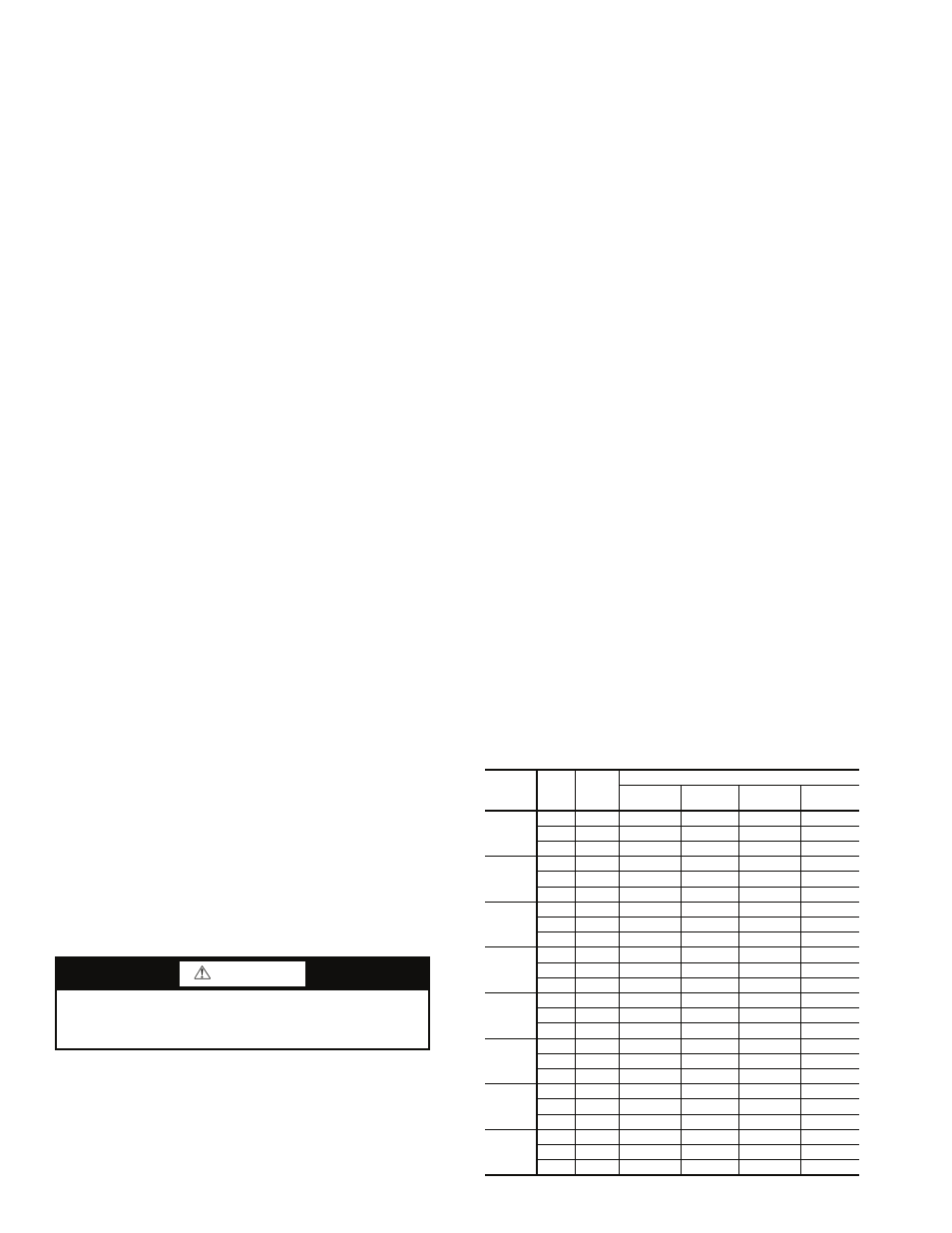

Table 23 — Coaxial Water Pressure Drop

WARNING

To avoid possible injury or death due to electrical shock,

open the power supply disconnect switch and secure it in

an open position before flushing system.

50PC

UNIT

SIZE

gpm

L/s

PRESSURE DROP, psi (kPa)

30 F

(-1 C)

50 F

(10 C)

70 F

(21 C)

90 F

(32 C)

015

1.9

0.12

1.0 (6.9)

0.6 (4.4)

0.5 (3.4)

0.4 (2.8)

2.8

0.18

1.8 (12.4)

1.4 (9.3)

1.1 (7.6)

1.0 (6.9)

3.8

0.24

3.3 (22.7)

2.5 (17.5)

2.1 (14.7)

1.9 (13.1)

018

2.3

0.14

2.1 (14.5)

1.4 (9.9)

1.1 (7.6)

0.9 (6.2)

3.4

0.21

3.4 (23.4)

2.6 (17.6)

2.1 (14.7)

1.8 (12.4)

4.5

0.28

5.9 (40.6)

4.6 (31.5)

3.9 (26.9)

3.4 (23.4)

024

3.0

0.19

2.2 (15.2)

1.7 (11.6)

1.4 (9.6)

1.2 (8.3)

4.5

0.28

4.0 (27.6)

3.2 (22.2)

2.8 (19.3)

2.5 (17.2)

6.0

0.38

7.2 (49.6)

5.9 (40.6)

5.2 (35.8)

4.7 (32.4)

030

3.8

0.24

1.3 (9.0)

0.9 (6.1)

0.7 (4.8)

0.6 (4.1)

5.6

0.35

2.3 (15.8)

1.8 (12.5)

1.5 (10.3)

1.4 (9.6)

7.5

0.47

4.2 (28.9)

3.4 (23.2)

2.9 (20.0)

2.6 (17.9)

036

4.5

0.28

1.8 (12.4)

1.4 (9.6)

1.2 (8.3)

1.0 (6.9)

6.8

0.43

3.1 (21.4)

2.4 (16.8)

2.1 (14.7)

1.9 (13.1)

9.0

0.57

5.4 (37.2)

4.4 (30.0)

3.8 (26.2)

3.4 (23.4)

042

5.3

0.33

2.3 (15.8)

1.8 (12.1)

1.5 (10.3)

1.3 (9.0)

7.9

0.50

4.3 (29.6)

3.5 (24.2)

3.1 (26.4)

2.8 (19.3)

10.5

0.66

7.9 (54.4)

6.5 (44.8)

5.7 (39.3)

5.2 (35.8)

048

6.0

0.38

1.8 (12.4)

1.5 (10.1)

1.3 (9.0)

1.2 (8.3)

9.0

0.57

3.4 (23.4)

3.0 (20.4)

2.7 (18.6)

2.6 (17.9)

12.0

0.76

6.2 (42.7)

5.5 (37.9)

5.1 (35.1)

4.8 (35.1)

060

7.5

0.47

3.4 (23.4)

2.8 (19.2)

2.4 (16.5)

2.2 (15.2)

11.3

0.71

6.8 (46.9)

5.9 (40.8)

5.4 (37.2)

5.0 (34.5)

15.0

0.95

12.6 (86.8) 11.1 (76.8) 10.3 (71.0)

9.6 (66.1)