Scroll compressor rotation, Unit start-up cooling mode – Carrier AQUAZONE PCV015-060 User Manual

Page 28

28

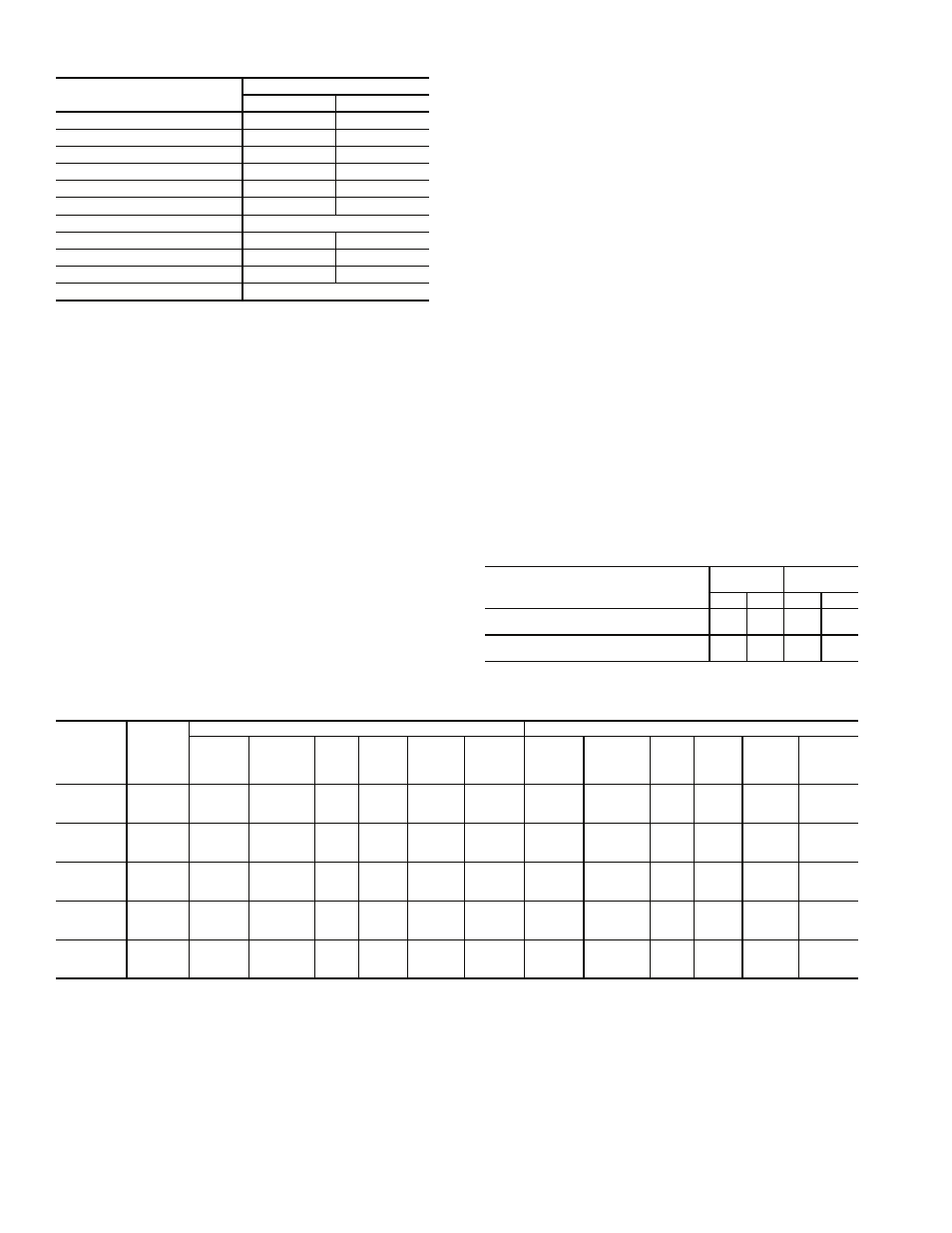

Table 14 — Operating Limits — 50PCH,PCV Units

LEGEND

Scroll Compressor Rotation —

It is important to

be certain compressor is rotating in the proper direction. To

determine whether or not compressor is rotating in the prop-

er direction:

1. Connect service gages to suction and discharge pressure

fittings.

2. Energize the compressor.

3. The suction pressure should drop and the discharge

pressure should rise, as is normal on any start-up.

If the suction pressure does not drop and the discharge

pressure does not rise to normal levels:

1. Turn off power to the unit. Install disconnect tag.

2. Reverse any two of the unit power leads.

3. Reapply power to the unit and verify pressures are correct.

The suction and discharge pressure levels should now move

to their normal start-up levels.

When the compressor is rotating in the wrong direction, the

unit makes more noise and does not provide cooling.

After a few minutes of reverse operation, the scroll com-

pressor internal overload protection will open, thus activating

the unit lockout. This requires a manual reset. To reset, turn the

thermostat on and then off.

NOTE: There is a 5-minute time delay before the compressor

will start.

Unit Start-Up Cooling Mode

1. Adjust the unit thermostat to the warmest position.

Slowly reduce the thermostat position until the compres-

sor activates.

2. Check for cool air delivery at unit grille a few minutes

after the unit has begun to operate.

3. Verify that the compressor is on and that the water flow

rate is correct by measuring pressure drop through the

heat exchanger using P/T plugs. See Table 15. Check the

elevation and cleanliness of the condensate lines; any

dripping could be a sign of a blocked line. Be sure the

condensate trap includes a water seal.

4. Check the temperature of both supply and discharge wa-

ter. Compare to Tables 16-22. If temperature is within

range, proceed. If temperature is outside the range, check

the cooling refrigerant pressures in Tables 16-22.

5. Check air temperature drop across the coil when com-

pressor is operating. Air temperature drop should be

between 15 and 25 F.

Table 15 — Water Temperature Change

Through Heat Exchanger

Table 16 — 50PC015,018 Typical Unit Operating Pressures and Temperatures

LEGEND

AIR LIMITS

50PCH,PCV

Cooling (F)

Heating (F)

Min. Ambient Air – db

45

39

Rated Ambient Air – db

80.6

68

Max. Ambient Air – db

110

85

Min. Entering Air – db/wb

50

40

Rated Entering Air – db/wb

80.6/66.2

68

Max. Entering Air – db/wb

110/83

80

WATER LIMITS

Min. Entering Water

30

20

Normal Entering Water

50-110

30-70

Max. Entering Water

120

90

Normal Water Flow

2.5-3.0 gpm per ton

db — Dry Bulb

wb — Wet Bulb

WATER FLOW RATE (GPM)

COOLING

RISE (F)

HEATING

DROP (F)

Min

Max

Min

Max

For Closed Loop: Ground Source or

Cooling/Boiler Systems at 3 gpm/ton

9

12

4

8

For Open Loop: Ground Water Systems at

1.5 gpm/ton

20

26

10

17

ENTERING

WATER

TEMP

(F)

WATER

FLOW

(GPM/ton)

COOLING

HEATING

Suction

Pressure

(psig)

Discharge

Pressure

(psig)

Super-

heat

(F)

Sub-

cooling

(F)

Water

Temp

Rise

(F)

Air Temp

Drop

(F) DB

Suction

Pressure

(psig)

Discharge

Pressure

(psig)

Super-

heat

(F)

Sub-

cooling

(F)

Water

Temp

Drop

(F)

Air Temp

Rise

(F) DB

30

1.5

120-130

155-175

27-32

11-16

16.9-19.9

16-22

73- 83

268-288

8-13

4- 9

6.1- 8.1

15-21

2.25

120-130

142-162

27-32

9-14

12.5-14.5

17-23

75- 85

270-290

8-13

4- 9

4.4- 6.4

16-22

3

120-130

128-148

27-32

9-14

8.1-10.1

17-23

78- 88

272-292

8-13

4- 9

2.9- 4.9

16-22

50

1.5

137-147

220-240

16-21

10-15

17.0-19.0

16-22

102-112

295-315

8-13

8-13

9.1-11.1

20-26

2.25

137-147

206-226

16-21

8-13

12.6-14.6

17-23

106-116

297-317

8-13

8-13

6.9- 8.9

21-27

3

137-147

192-212

16-21

8-13

8.4-10.4

17-23

110-120

299-319

8-13

8-13

4.7- 6.7

21-27

70

1.5

142-152

287-307

7-12

10-15

15.9-17.9

16-22

131-141

324-344

9-14

10-15

12.1-14.1

25-33

2.25

142-152

273-239

7-12

8-13

11.8-13.8

17-23

137-147

326-346

9-14

10-15

9.3-11.3

26-34

3

142-152

259-279

7-12

8-13

7.8- 9.8

17-23

144-154

328-348

9-14

10-15

6.6- 8.6

26-34

90

1.5

146-156

375-395

6-11

10-15

14.9-16.9

16-22

174-184

360-380

10-15

12-17

15.8-17.8

32-40

2.25

146-156

361-381

6-11

8-13

11.0-13.0

17-23

180-190

367-387

11-16

12-17

11.9-13.9

33-41

3

146-156

347-367

6-11

8-13

7.2- 9.2

17-23

187-197

374-394

12-17

12-17

8.0-10.0

33-41

110

1.5

154-164

478-498

6-11

10-15

14.0-16.0

16-22

—

—

—

—

—

—

2.25

154-164

461-481

6-11

8-13

10.2-12.2

16-22

—

—

—

—

—

—

3

154-164

445-465

6-11

8-13

6.5- 8.5

16-22

—

—

—

—

—

—

DB

— Dry Bulb

—

— No Heating Operation in This Temperature Range