Pressure sensor high/low calibration, Arc 6000 ce & s – TeeJet ARC-6000 User Manual

Page 14

98-05017

Rev.- 1

2-4

ARC 6000

CE & S

TANDARD

V

ERSION

Once the initial calibration number has been entered into the console, proceed to section 2.6.1.4 to fine tune the flowmeter

for maximum accuracy.

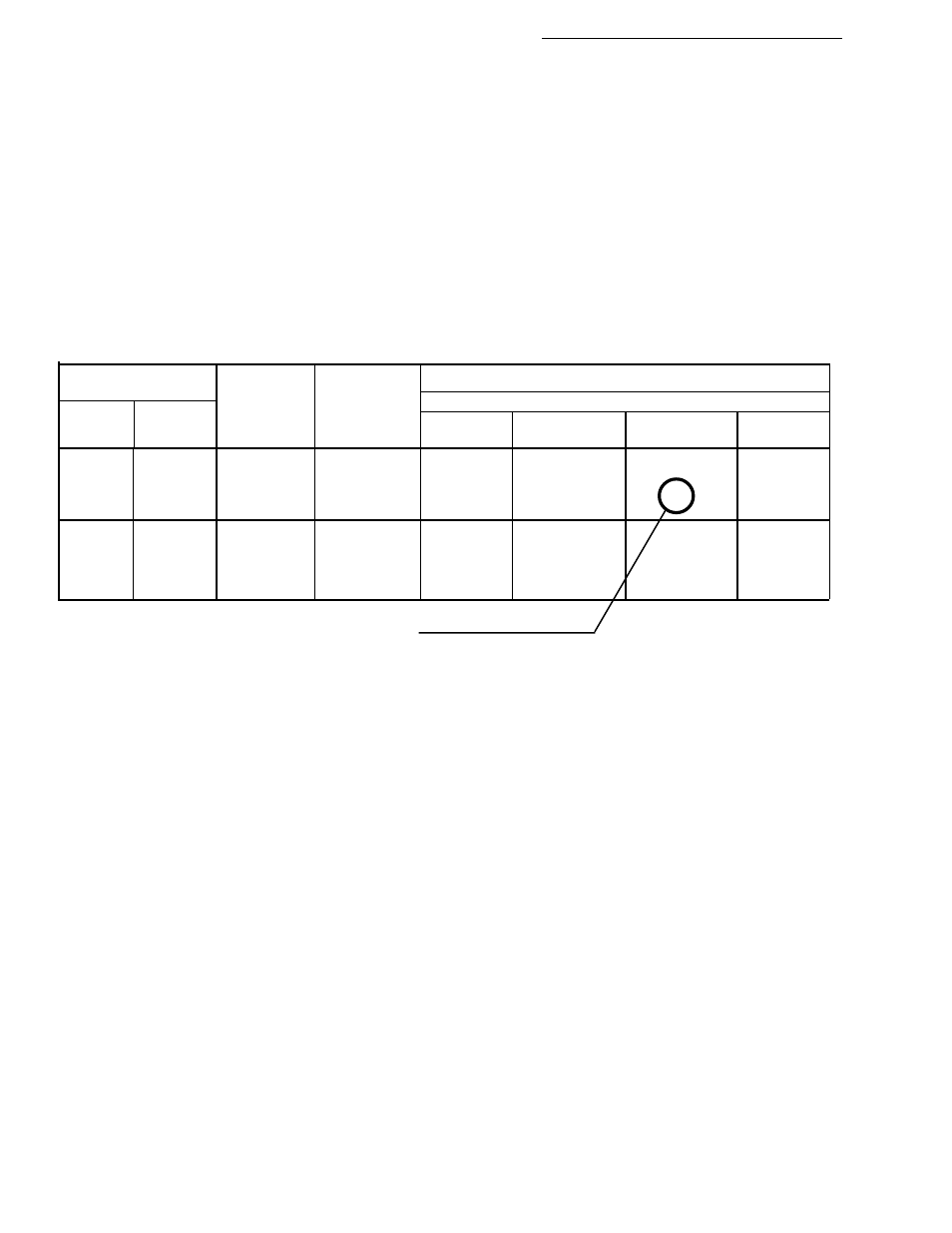

2.6.1.2. DETERMINING THE PRESSURE SENSOR INITIAL CALIBRATION NUMBER

The Pressure Sensor Calibration Number can be found by determining the "Gallons per Acre" rating for the type of nozzles

being used. First find the chart that represents the nozzle series you will use and the nozzle spacing of your boom. Then find

the nozzle size needed for the range of speeds and the rate needed. When the nozzle has been selected find the column of

nozzle ratings in "Gallons per Acre" at 10 MPH. Then, on the left of the chart, find the horizontal line representing the

ratings at 30 PSI. Where the column and row intersect you will find the "Gallons per Acre" rating of your nozzles at 10

MPH and 30 PSI. This is the value to enter into the console as the pressure sensor Cal. #. For example, in the following chart,

for a floodjet K-SS10 nozzle, the row for 30 PSI and column for 10 MPH cross at 26.0 gallons per acre, the pressure sensor

cal. number for this particular nozzle.

NOTE: We recommend that these tests be done using water, and only after neutralizing the tank and system.

4

Gallons per Acre

Type

Floodjet

Tip No.

TK-SS10

TK-SS15

Liquid

Capacity

40" Spacing

Floodjet

Pressure

in

6

8

10

12

Nozzle

in PSI

GPM

MPH

MPH

MPH

MPH

10

1.0

25.0

16.6

14.9

12.4

K-SS10

20

1.4

35.0

26.0

21.0

17.5

30

1.7

43.0

32.0

26.0

21.0

40

2.0

50.0

37.0

30.0

25.0

10

1.5

37.0

28.0

22.0

18.6

K-SS15

20

2.1

53.0

39.0

32.0

26.0

30

2.6

64.0

48.0

39.0

32.0

40

3.0

74.0

56.0

45.0

37.0

Use this number as the cal. number in this example.

Use the following procedure to enter the flow sensor calibration number.

A. Set the console to the following positions;

Power

ON

Mode Selector

SET- UP

Master Switch

OFF

Display Selector

TOTAL APPLIED

B. Use the INC/DEC switch to select the desired flow sensor calibration number.

2.6.1.3. PRESSURE SENSOR HIGH/LOW CALIBRATION

The pressure sensor's low and high values must be set to match the readings from your pressure gauge following the proce-

dure below.

SETTING THE LOW SIDE:

A. Set the console to the following positions;

Power Switch

ON

Setup/Operate Switch

OPERATE

Display Selector Switch

PRIME

Master Switch

ON

At least one Boom Switch

ON (to release any trapped pressure)

(May have to remove nozzle if it has a check valve)

Ground speed

0 (zero)

GSO Switch

OFF